Part number 463622

DFD, FD, FSD Series

Grille Installation

Installation Instruction Supplement

Refer to:

‘Installation Instructions for FD, DFD, SSFD Models Fire’

(Part #452763)

‘Installation Instructions for FSD-XXX, DFD-XXX, CFSD-XXX, &

SSFSD-XXX, Series Fire & Combination Fire Smoke Damper’

(Part #461336)

‘Installation Instructions for FD & DFD 150X Series Curtain Fire

Damper’ (Part #453946)

“UL CLASSIFIED

(see complete marking on product)”

“UL CLASSIFIED to Canadian safety standards

(see complete marking on product)”

Standards UL555 & UL555S

Classifications filed at UL under Listing #R13317

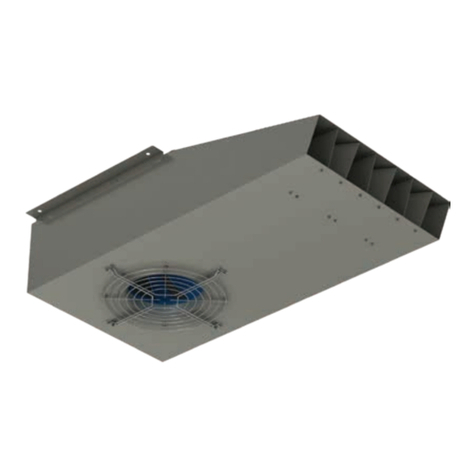

11/2in. x 11/2in.

16 ga. angles

(minimum)

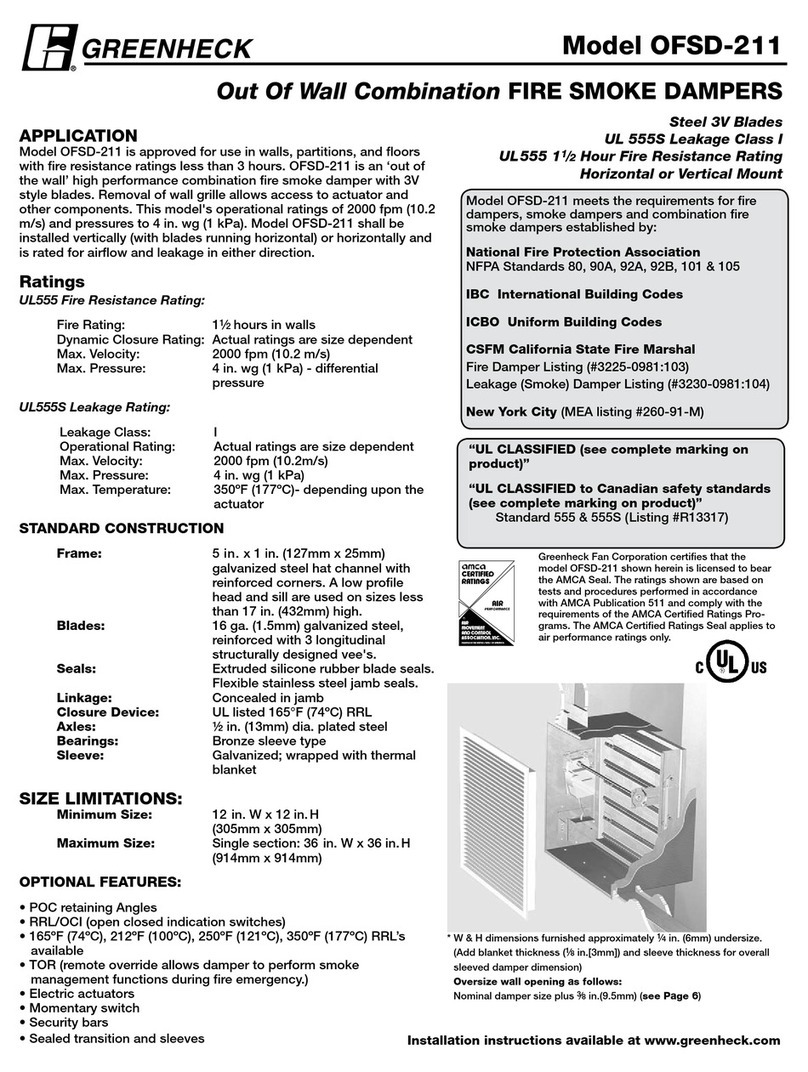

Grille (supplied

by others)

Damper sleeve

Fig. 2

Copyright ©2007 Greenheck Fan Corporation

Grille Installation Supplement R3 July 2007

Clearance Requirements

There is no minimum clearance requirement between the wall opening and

the sleeve exterior. However, to facilitate installation, clearances between the

wall opening and the damper sleeve are recommended. Although there is no

maximum allowable clearance, a minimum overlap of ½ in. (13mm) between the

wall and the flange/retaining angle must be maintained.

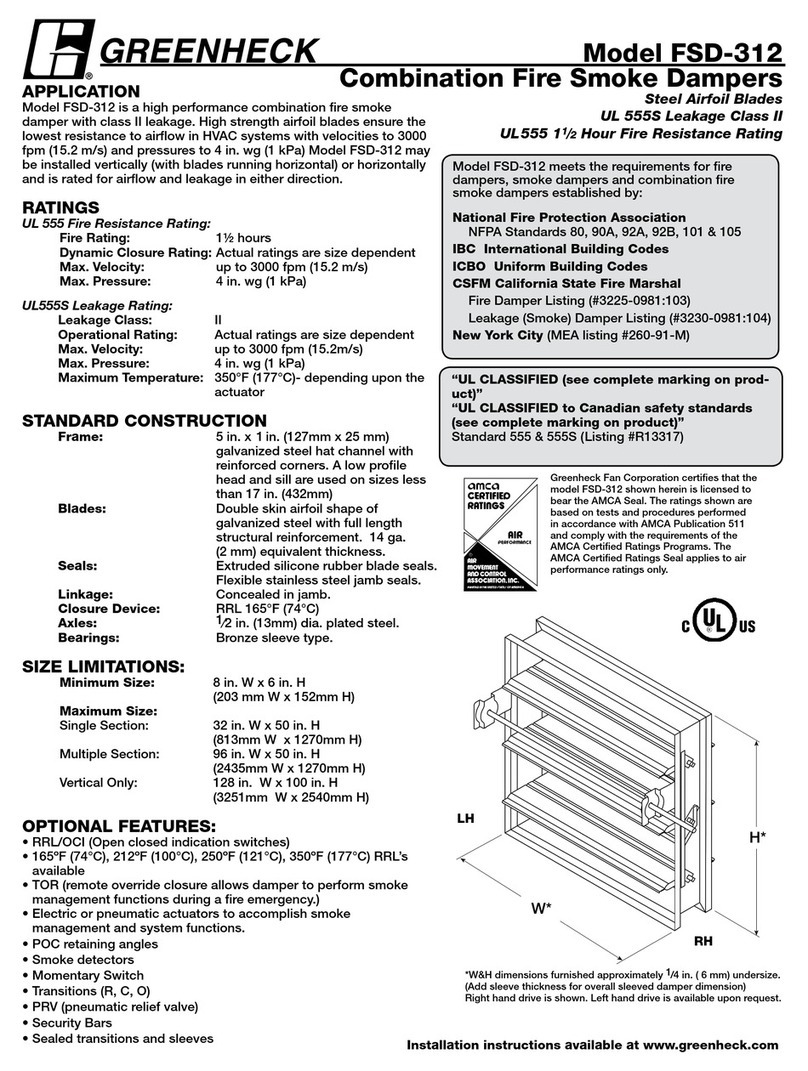

1. Single Flange Method

Damper/sleeve assemblies must be installed in wall openings using flanges

and sheet metal screws as illustrated and describe below. This method is only

applicable to 1½ hour rated damper; the 3 hour damper and dampers larger than

36 in. x 36 in. (914mm x 914mm) will require a minimum of 1½ in. x 1½ in. (38mm

x 38mm) legs.

• Flange on front (grille end) of sleeve must be a minimum of 16 ga. (1.6mm)

steel and have a 5/8 in. minimum flange leg. Using #10 sheet metal screws,

screw from inside of sleeve through the rear portion of the studs (as shown

in Figure 1). Space screws a maximum of 6 in. (152mm) on center and a

maximum of 2 in. (51mm) from the corners (minimum of two screws per side).

No retaining angles are required on the side of wall opposite from the grille.

2. Retaining Angle Method

Damper/sleeve assemblies must be installed in wall and floor openings using

retaining angles on at least one side of the wall or floor as described below:

• Retaining angles must be a minimum of 16 ga. (1.6mm) and have a minimum of

1½ in. x 1½ in. (38mm x 38mm) legs (see Figure 2).

• For grille installation on fire damper up to 36 in. x 36 in. (914mm x 914mm)

maximum, angle legs may be reversed and one leg inserted into the wall/floor

opening providing the required clearance is maintained between angle leg

fastener and the wall/floor opening. Note: Screws used to attach grille are

allowed to penetrate reversed angle leg.

• Retaining angles must be attached to the damper using one or more of the

following methods of attachment (refer to label on outside of sleeve for ‘No

Screw’ area):

• Tack or spot welds

• #10 (¾ in. [19mm] max.) sheet metal screws

• ¼ in. (6mm) bolts and nuts

• 3/16 in. (4mm) steel pop rivets

A minimum of two connections per side, top and bottom, 12 in. (305mm) O.C.

maximum. The angles must be attached to all four sides of the sleeve. Ensure

that attachment device does not interfere with the operation of the damper and

the free movement of the damper blades. The angles need not be attached to

each other at the corners.

• Retaining angles must be attached to the partition using one of the methods

below (see single side retaining angle-vertical mount supplement part

#462099):

• Drywall screws of a length such that the screw engages the steel

stud/track by ½ in. (13mm) (steel framing).

• Drywall screws of a length such that the screw engages the wood

stud by 1¾ in. (44mm) (wood framing).

• Steel anchors or self tapping concrete screws penetrating masonry or

block 1¼ in. (31mm).

Grille (supplied

by others)

Steel stud

5/8 in. x 1 in.

16 ga. angles

minimum

#10 sheet metal

screws spaced 6 in.

on center and a

maximum of 2 in.

from the corners

(minimum of 2

screws per side).

Screw into rear

portion of the studs

so as to avoid space

conflicts with the

grille assembly.

Fig. 1