Greenheck CUBE-098 Installation guide

Other Greenheck Fan manuals

Greenheck

Greenheck SQ User manual

Greenheck

Greenheck Vektor-HS User manual

Greenheck

Greenheck SP Series User manual

Greenheck

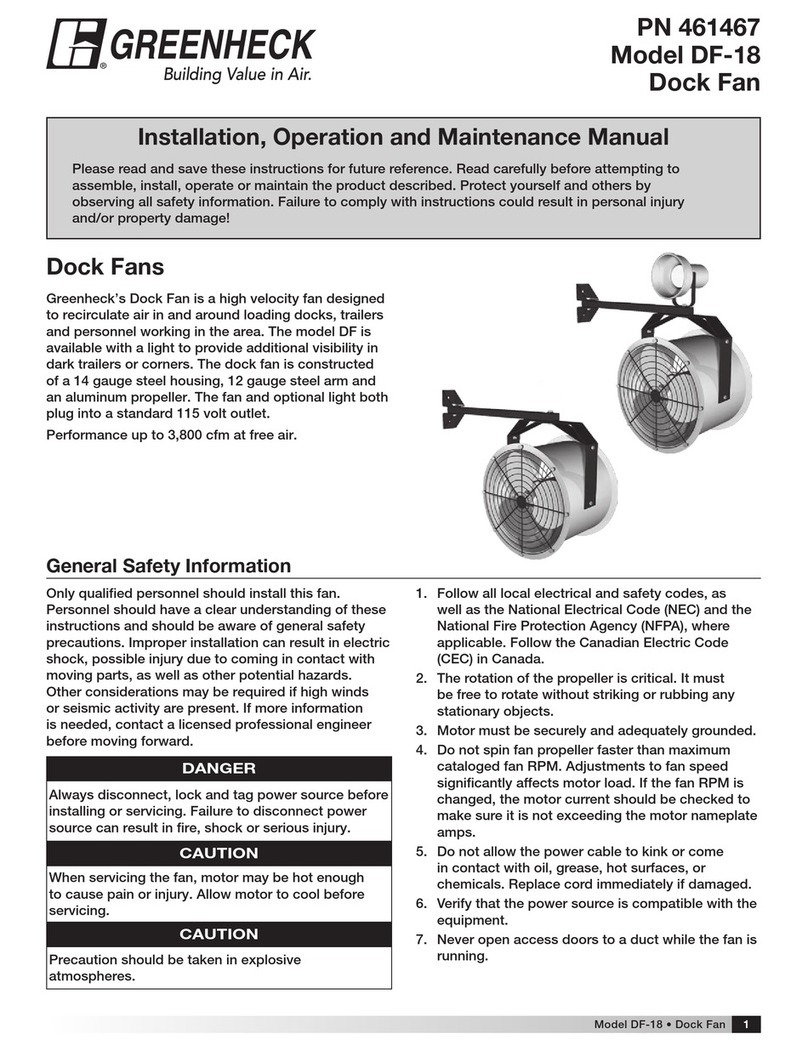

Greenheck DF-18 User manual

Greenheck

Greenheck ERV User manual

Greenheck

Greenheck XG-Dual User manual

Greenheck

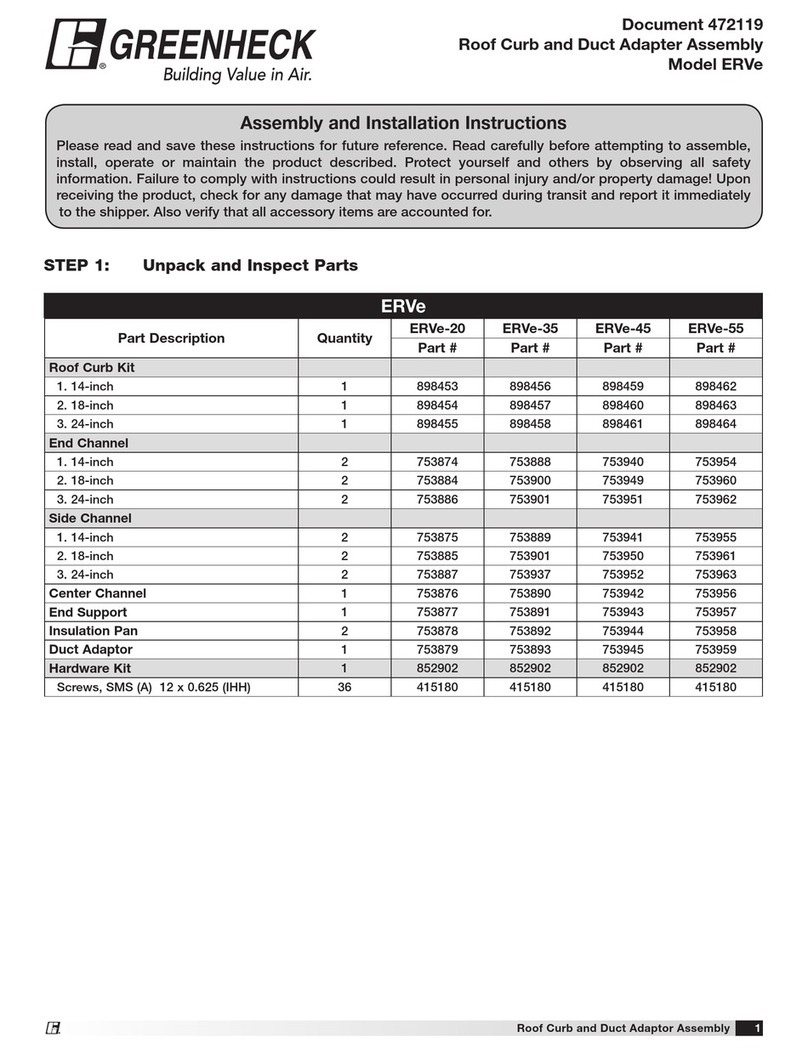

Greenheck ERVe-20 Instruction manual

Greenheck

Greenheck SP-L User manual

Greenheck

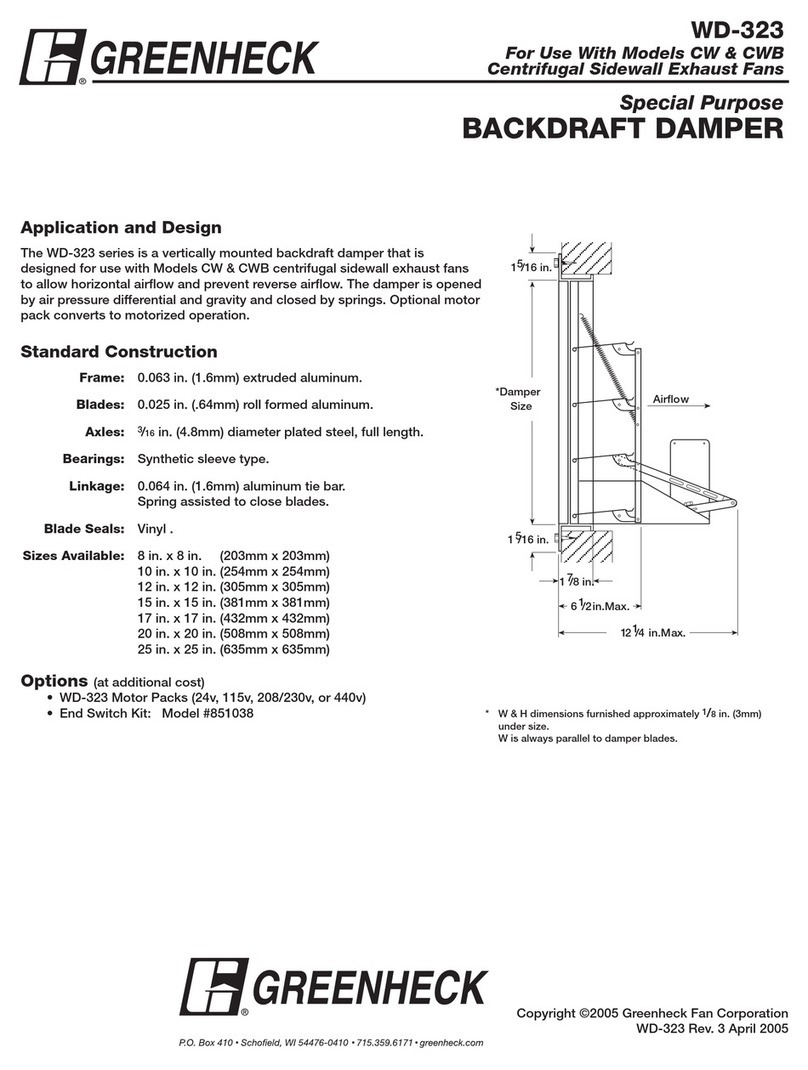

Greenheck WD-323 User manual

Greenheck

Greenheck QEI-L User manual

Greenheck

Greenheck QEID FJ User manual

Greenheck

Greenheck SQ Series User manual

Greenheck

Greenheck SE1 User manual

Greenheck

Greenheck CRD-3 Series Installation guide

Greenheck

Greenheck SBCE User manual

Greenheck

Greenheck SFD User manual

Greenheck

Greenheck TCB Series User manual

Greenheck

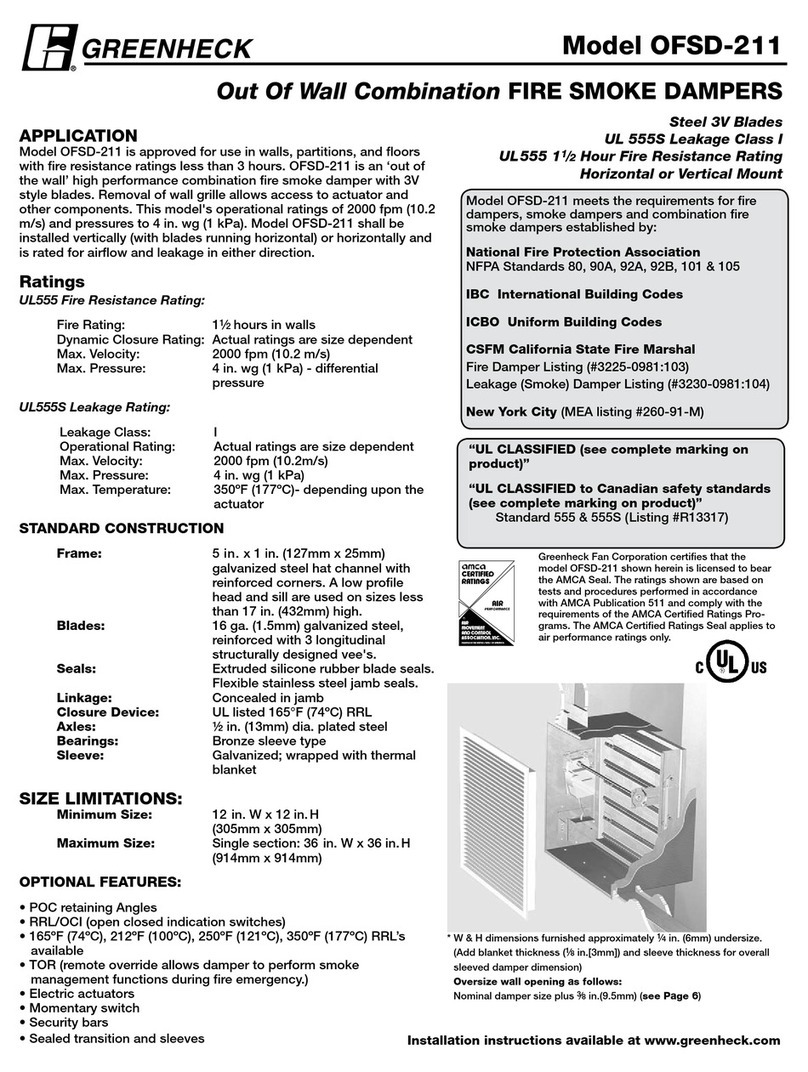

Greenheck OFSD-211 User manual

Greenheck

Greenheck SQ User manual

Greenheck

Greenheck ERVe Series User manual

Popular Fan manuals by other brands

ELTA FANS

ELTA FANS H03VV-F installation guide

Hunter

Hunter 20714 Owner's guide and installation manual

Emerson

Emerson CARRERA VERANDA CF542ORB00 owner's manual

Hunter

Hunter Caraway Owner's guide and installation manual

Panasonic

Panasonic FV-15NLFS1 Service manual

Kompernass

Kompernass KH 1150 operating instructions