XG-Round Retrofit VAV Terminals Rev 2 4

Field Electrical Wiring

5All field wiring must comply with local building codes and

NEC. (ANSI/NFPA 70-2002)

5When Applicable, electrical control and piping diagrams are

attached to exterior of XG-Round Retrofit Air Terminal.

5Use copper only conductors.

5XG-Round Retrofit Air Terminal must be properly grounded

per NEC 424-14 and 250.

5Always check product label for voltage and current data to

determine the proper wire size and over current protection.

5The control cabinet contains live electrical parts.

5Contacting these parts with power applied may cause seri-

ous injury or even death.

5The control panel cover must be closed or in place before

applying electric power to the XG-Round Retrofit Air Termi-

nal.

5These recommendations are not meant to precluded NEC

requirements or applicable local building codes and are the

sole responsibility of the installing contractor.

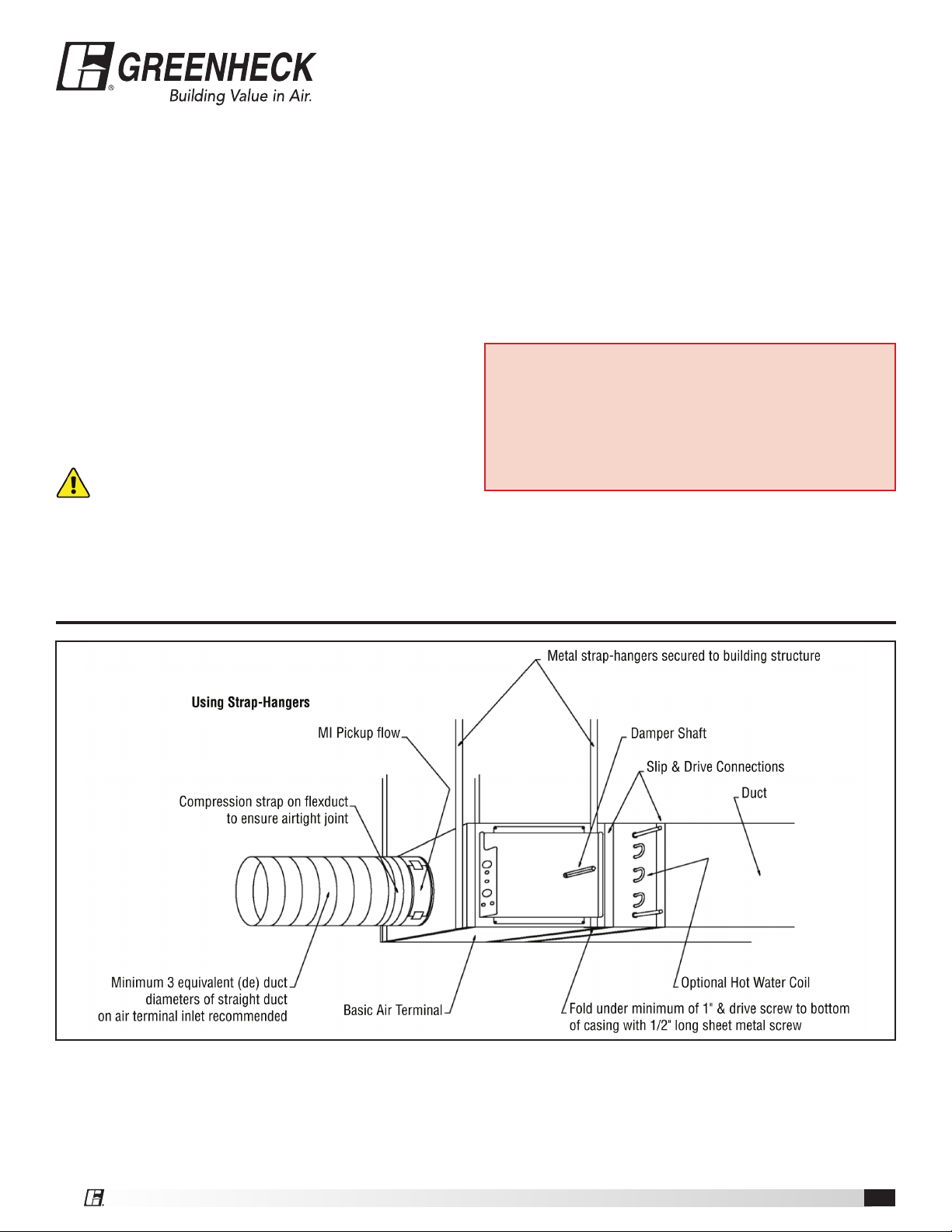

Important

If equipped with pneumatic controls, the orientation of the XG-

Round Retrofit Air Terminal unit is critical. The pneumatic controls

must be mounted right side up. The XG-Round Retrofit Air Terminal

must be level within + or – 10 degrees of horizontal, both parallel

to the air flow and at right angle of air flow. The control side of the

XG-Round Retrofit Air Terminal is labeled with an arrow indicat-

ing up. Unless otherwise noted, most electric, analog electronic

and digital are not position sensitive and may be installed in any

orientation.

Controls

For information on controls provided by other manufactures and

installed on the XG-Round Retrofit Air Terminals, contact the local

branch or dealer. Installing the Air Terminal in a different location

than noted on the XG-Round Retrofit Air Terminal label and build-

ing plans, may result in excessive start up labor and is the sole

responsibility of the contractor.

Important

XG-Round Retrofit Air Terminals with digital controls, if factory pro-

grammed, incorporate specific communication addresses.

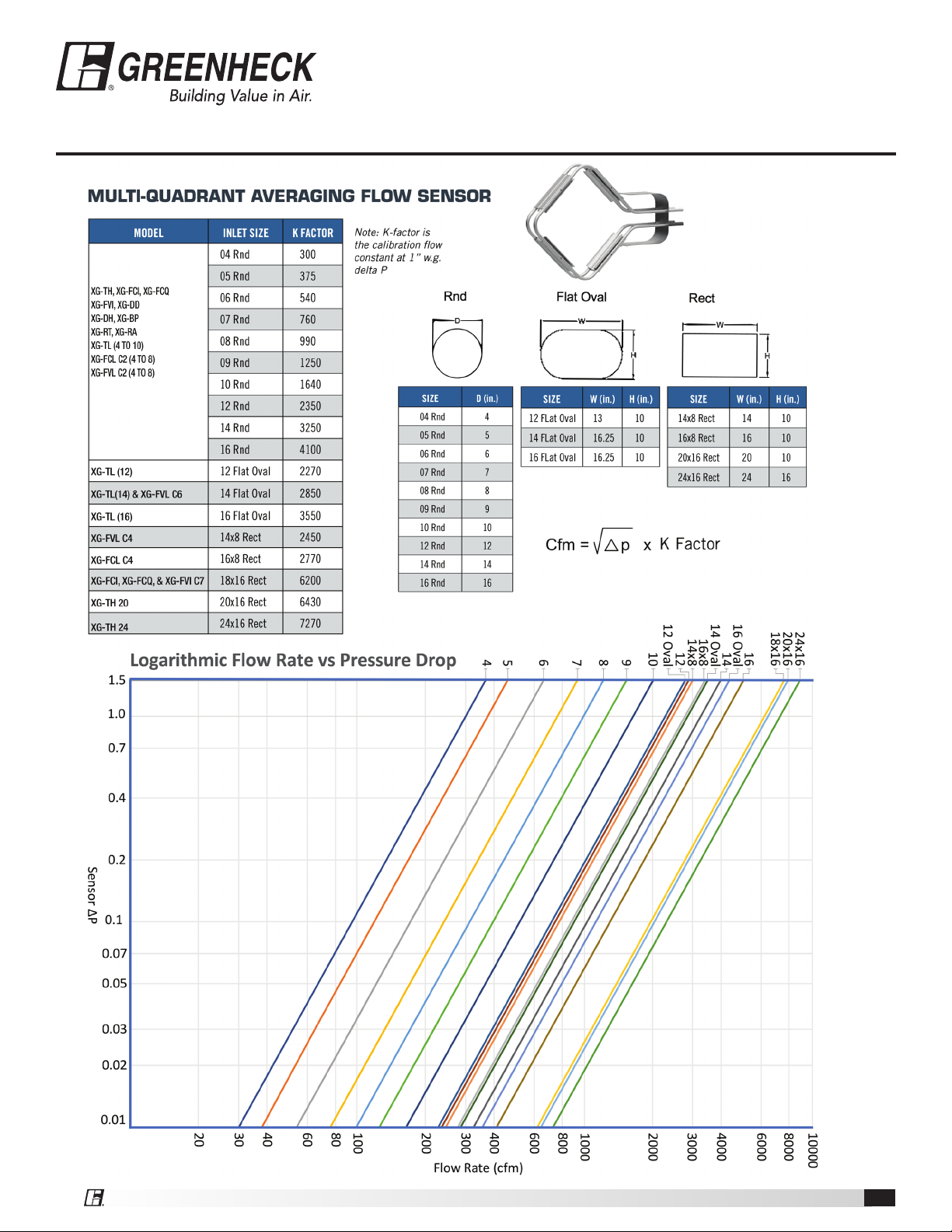

Inlet Flow Sensor

XG-Round Retrofit Air Terminals are shipped with factory

installed (where applicable) pressure differential inlet flow sensors

in the primary inlet. See figure 3 for calibration curve and K

factors.

Labeling

XG-Round Retrofit Air Terminals are shipped from the factory with

multiple information labels.

Control Sequence Label: Affixed to the exterior of the

XG-Round Retrofit Air Terminal casing. Displays piping/wir-

ing diagram, control sequence number and any optional

components.

Terminal I.D. Label: Affixed to the exterior of XG-Round

Retrofit Air Terminal. Shows tagging, representative name,

sales order number, applicable certifications, model number,

Made in USA, any applicable electrical data and UL compli-

ance markings.

AHRI Certification Label: Identifies applicable industry

test standard and certifies Air Terminal is in compliance.

Orientation Label: Identifies the proper air flow direction

and top of Round Retrofit Air Terminal.

Troubleshooting

Investigating Noise Complaints

5Noise from a Round Retrofit Air Terminal can be due to a

variety of conditions and can be difficult to eliminate.

5The first step is to isolate the type, source and direction.

5Generally noise heard at the air outlet is considered a dis-

charge type.

5Noise heard through the ceiling is considered radiated noise.

5For detailed information concerning noise transmission in

buildings, refer to AHRI Standard 885-2008,

“Procedure for estimating occupied space sound levels in

the application of Air Terminals and air outlets”.

Discharge Noise

5This is usually caused by high static or little to no internal duct

lining downstream of the Round Retrofit Air Terminal.

5It can sometimes be caused by air outlet itself.

5Air outlet generated sounds can be reduced by reducing flow

or increasing an outlet size.

5Reducing static pressure, flow or adding additional down-

stream attenuation materials will reduce discharge sounds

from the Air Terminal.

Radiated Noise

5Radiated noise is most commonly associated with Fan Pow-

ered Terminals.