Copyright © 2008 Greenheck Fan Corporation

FSDR-511 Rev. 6 June 2008

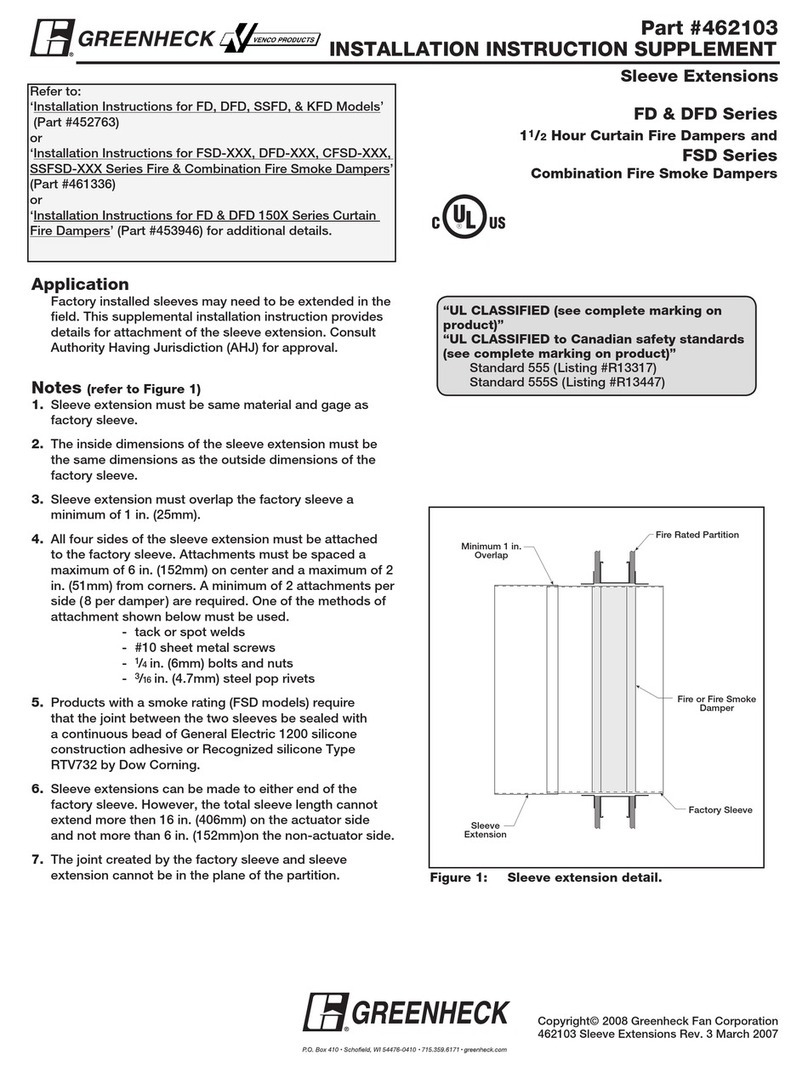

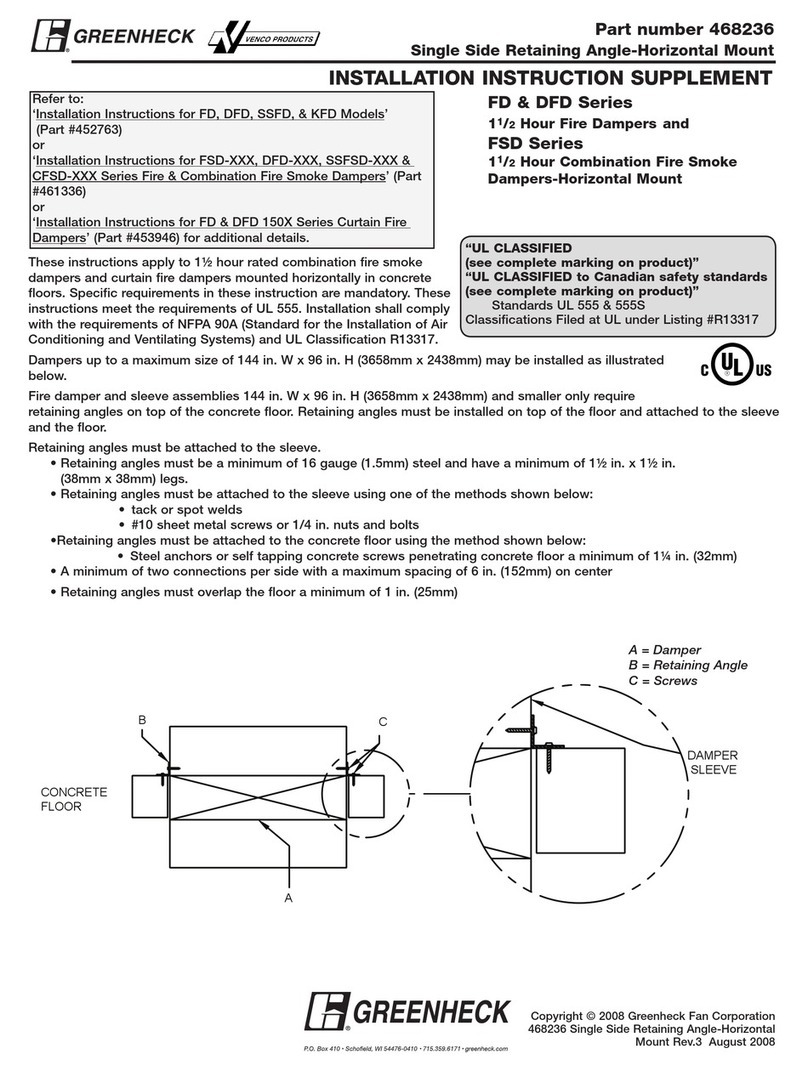

3.375 IN.

FUSIBLE LINK

(standard)

LOCATION

CLEARANCE FOR

EXPANSION

TOP VIEW OF DAMPER

6 IN. MAX

SLEEVE LENGTH

Wall

DUCT

CONNECTION

AREA

AIRFLOW

1.5 IN.

ACTUATOR

16.00 IN MAX

OPTIONAL BLADE POSITION

INDICATOR AND/OR ELECTRIC

LINK.

DUCT

CONNECTION

AREA

1.5 IN.

1.50 IN.

Optional

Second

Retaining

Plate

Do not place retainer

plate in this groove

5.375 in. 3.06 in. or 7.43 in.*

* 7.43 in. when OCI, RRL, RRL/OCI,

TOR, or PRV is selected

Retaining plate

Specificatons

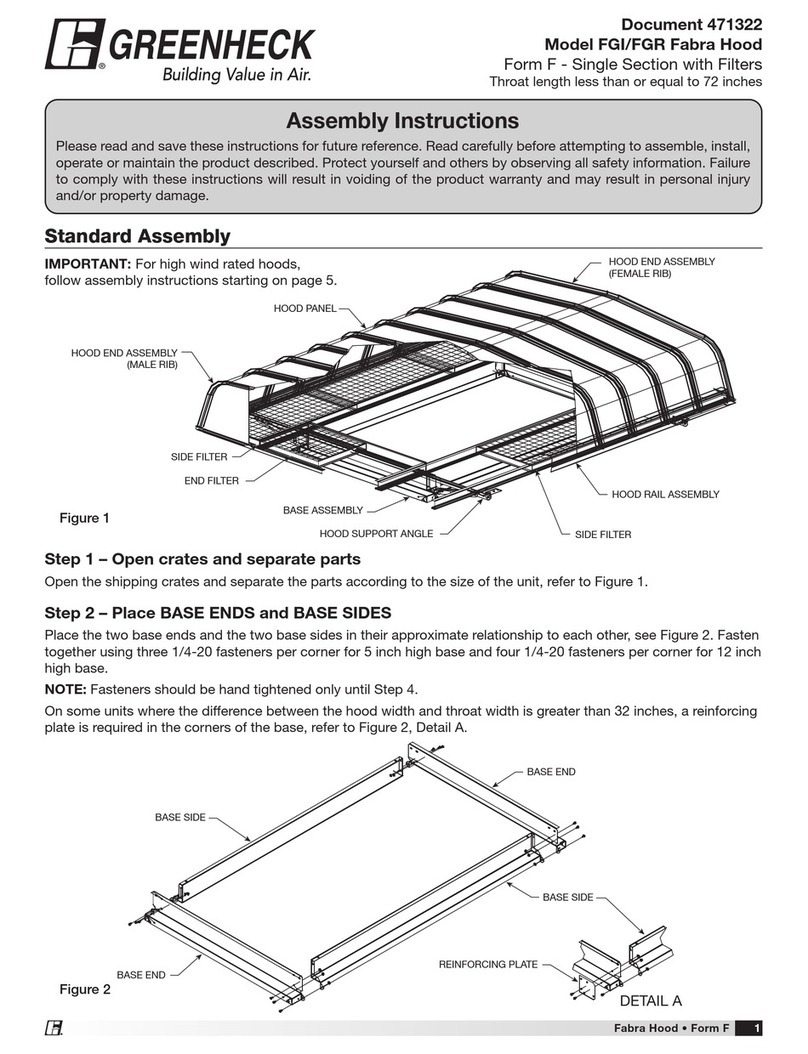

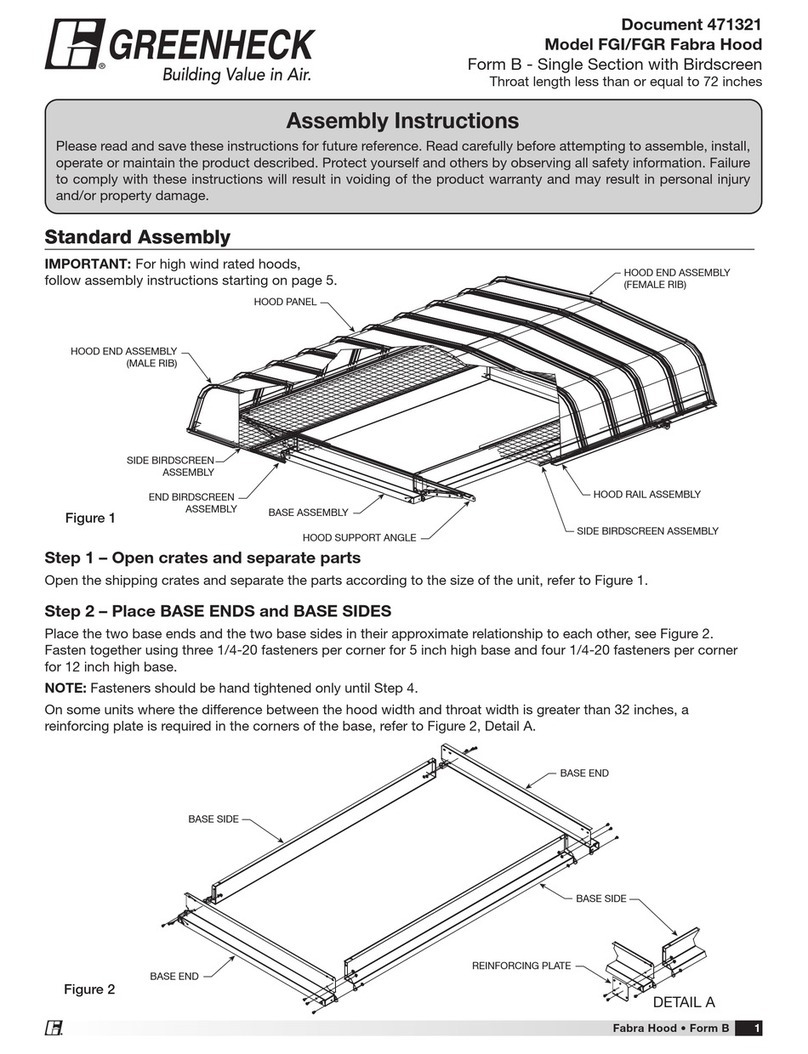

True Round Combination Fire Smoke Dampers meeting the

following specifications shall be furnished and installed

where shown on plans and/or as described in schedules.

Dampers shall meet the requirements of the latest edition of

NFPA 80, 90A, 92A, 92B, 101, & 105.

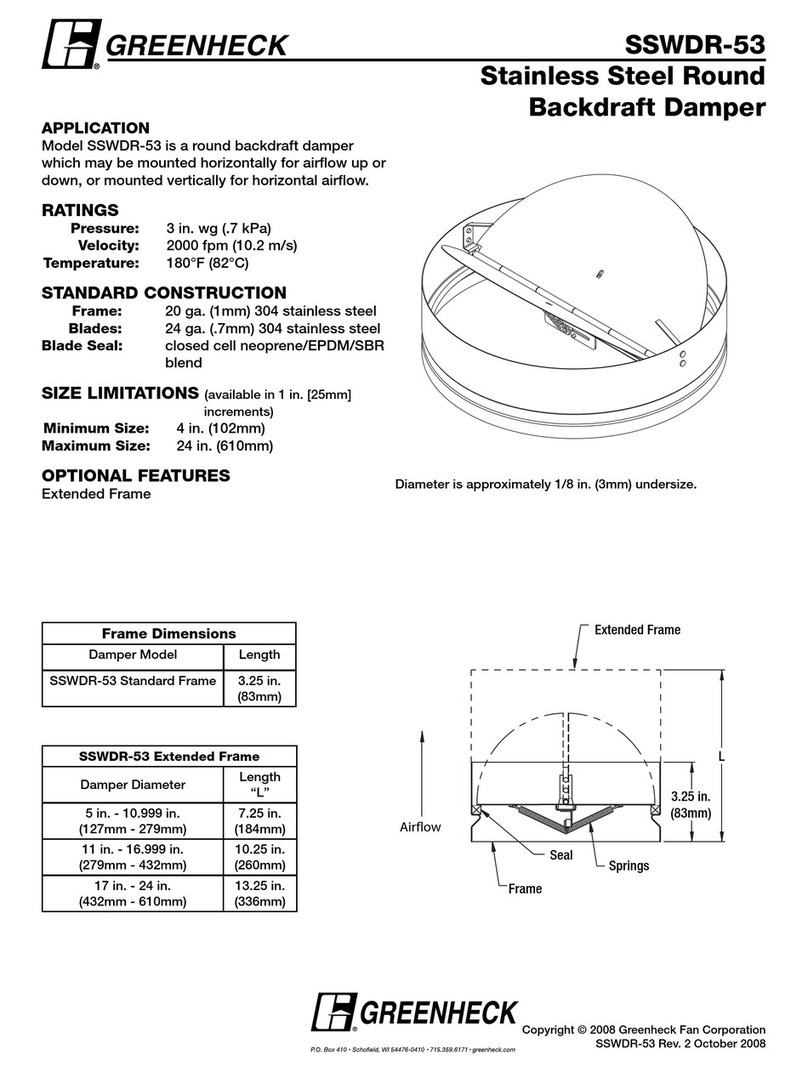

Damper shall be constructed of 20 ga. (1mm) galvanized

steel frame/sleeve; blade constructed of double skin

galvanized steel round style blade; silicone rubber blade

seal; ½ in. plated steel axles; stainless steel bearing.

Damper is provided with one retainer plate.

Dampers shall be tested, rated and labeled in accordance

with the latest edition of UL standards 555 and 555S.

Dampers shall have a UL555 fire rating of 1½ hours. Each

damper shall be equipped with a heat responsive device,

which has been tested and approved for use with the

damper assembly in accordance with UL555. The heat

responsive device shall have a temperature rating of

(specifier select one or the following) 165°F (74°C), 212°F

(100°C), 286°F (141°C), or 350°F (177°C).

Dampers shall be UL labeled for use in dynamic systems.

The damper shall have a dynamic closure airflow rating

equal to or greater than the airflow at the dampers installed

location and a dynamic closure pressure rating of 4 in. wg

(1kPa). All UL555 and UL555S dynamic closure and leakage

ratings shall be qualified for airflow and pressure in either

direction through the damper. UL ratings shall allow for

mounting damper vertically or horizontally.

Dampers shall have a UL555S leakage rating of Class I and

a temperature rating of 250°F (121°C) minimum. Dampers

shall have a UL555S operational airflow rating equal to

or greater than the airflow at its installed location and an

operational pressure rating of 4 in. wg (1kPa). Damper

actuators shall be factory mounted and qualified for use

with the damper in accordance with UL555S.

Damper actuators shall be (specifier select one of the

following) electric type for 120 or 24 volt operation and

pneumatic type for 25 psi minimum (30 psi maximum)

operation. Manufacturer’s submittal data shall indicate

actuator space requirements around the damper.

The Damper manufacturer’s submittal data shall certify all

air performance pressure drop data is tested in accordance

with the AMCA certified ratings program for test figures

5.2, 5.3, and 5.5. Damper air performance data shall be

developed in accordance with the latest edition of AMCA

Standard 500-D.

Basis of design is Greenheck’s model FSDR-511.