PG1 Tester

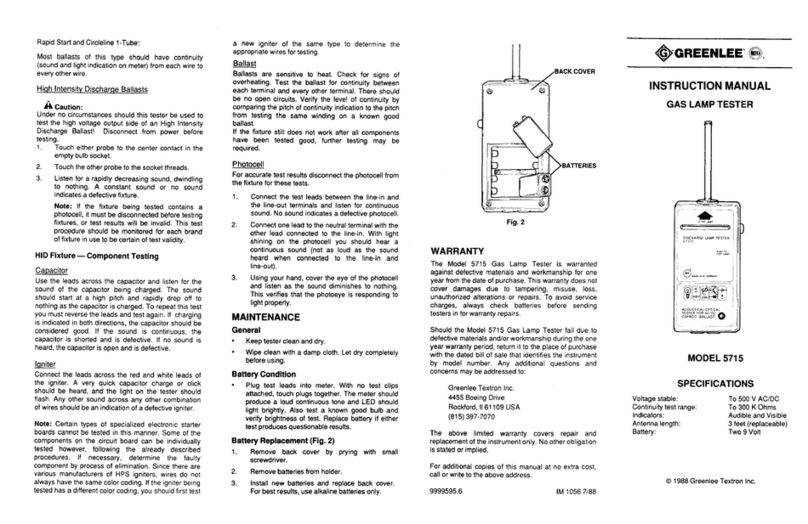

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

6

Setup

The following functions can be accessed before placing

the diode holder on the tool to be tested:

Choose language: Press the ON key. When the serial

number of the PG1 is displayed, press and hold ↓

until the language choices appear on the display. Use

↑and ↓to select “German” or “English”. Press √ to

conrm the selection.

Adjust contrast: Press the ON key. When the serial

number of the PG1 is displayed, press and hold the

↑key until “LCD Contrast” appears on the display.

The standard (default) setting comes up automatically

but can be changed by pressing ↑and ↓. Press √ to

conrm the setting.

Display charging stage: Press the ON key. When the

serial number of the PG1 is displayed, press and hold

the √ key until the charging status is displayed.

If the charging condition of the battery is less than

10%, replace the battery. To replace the battery,

remove the battery cover, open the battery shelf, and

replace with a new 9 V battery.

Operation

1. Press the ON key.

2. Place the PG1 LED (located on the diode holder)

onto the LED of the tool to be tested.

3. Briey touch the power trigger of the tool.

4. The PG1 will display the serial number of the tool

and, if available, the date code, the type designa-

tion, and special features of the tool.

Press √ to move to the next screen. In both of the

bottom lines of the display, the menu point “reset”

and “main menu” are indicated. The menu points

are triggered with the ↑and ↓keys, and selected

with the √ key. “Reset” sets the current delta-values

(values since the last maintenance) to zero after

maintenance has been performed. If you choose

“main menu”, you will go to the next screen.

5. Maintenance:

From the main menu you can select an additional

menu, which consists of the following points:

Reset: Sets the current delta-values to zero

(= a.m. menu point).

Indicating values: limit stops; by reset the delta-

value is set to zero, the “total” value remains as

it was and shows the total number of limit stops

(cycles) carried out with the tool. Use ↓to move

to the next page. Disconnection “on” means that

the circuit cuts off the motor after a completed

cycle. The bonus states how many crimps can be

made exceeding the determined number before

the start of the maintenance indication (ashing)

before the tool is going to be out of action (shuts

•

•

•

•

•

down for service). The menu point “limit stops“

shows the pre-adjusted number of limit stops until

the maintenance indication of the tool indicates

the next maintenance. On the next screen the

energy consumption is indicated. The delta-value

is set to zero again at reset, and the total value is

xed.

On page 4/5 the number of measurements is

indicated. At reset the delta-value is set to zero

again, and the total value remains xed. On page

5/5 the version of the circuit board and what it

was programmed to is displayed. Use the √ key to

return to the main menu.

Changing values: If you choose this menu point

with ι, you can set new maximum limit stops for

the beginning of the maintenance indication of

the tool. Use ↑and ↓to increase or decrease the

value. Press √ to move to the next screen, where

you are required to conrm the value you chose.

In the second menu point you can change the

value once more or readjust again the original

value in the third menu point. In the next screen

you can adjust the bonus-limit stops. A range of

0-255 is preset. 0 means that the bonus is set

on “innite”. In fact a maintenance which is due

is then indicated now as before but there is no

functional blocking. After this you are requested

to conrm the chosen value with the √ key. In the

next screen you select whether or not the tool

should turn the motor off after a completed cycle.

For this value, cutters are set at 0, while crimping

tools are set at 1. Conrm input with the √ key.

Afterwards the value can be changed once more

and the original value can be adjusted again. If

this value is conrmed with OK (!), you will go

back to the main menu.

6. Serial number (= entry window)

7. Control: The indicated values are for the manufac-

turer’s control.

8. Options: Refer to the “Setup” section of this

manual.

9. The PG1 automatically shuts off after 5 minutes of

inactivity.

•