Multi Carrier HXF 3302

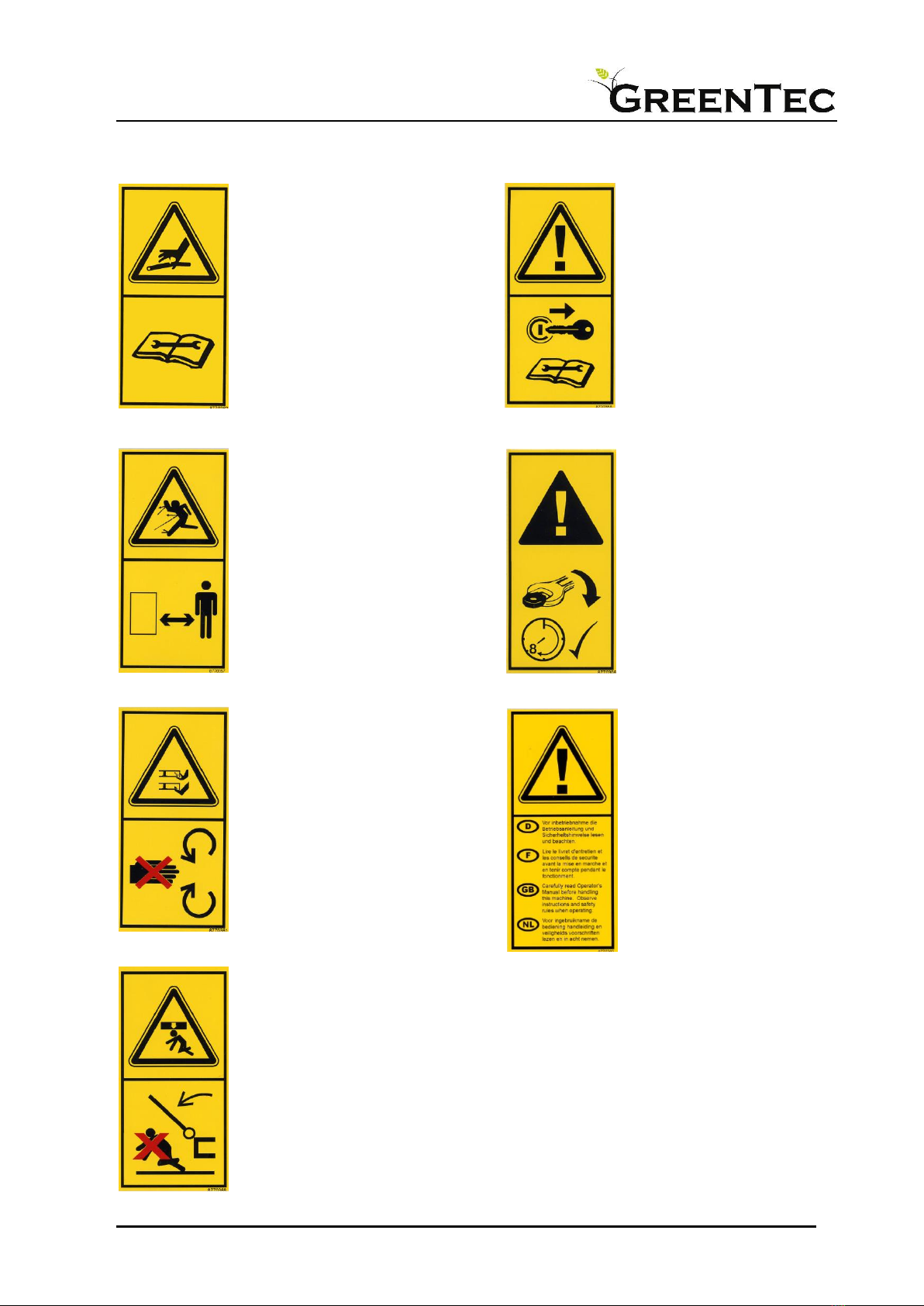

Follow the manufacturer’s instructions for attachment and removal of machine

from the tractor are warning signs to alert others to the type of machine working

in the vicinity. Signs should be placed at both ends of the work site and should

be in accordance with Department of Transport recommendations.

Ensure flails are of the type recommended by the manufacturer, are securely

fitted and are undamaged.

Ensure hydraulic pipes are correctly routed to avoid damage from chafing,

stretching, pinching or kinking.

Disengage the machine, stop the engine and remove the key before leaving the

tractor cab for any reason.

Clean up any debris left at the work site.

Ensure that when you remove the machine from the tractor it is secured in a

safe position using the stands provided.

Never:

Never operate the machine with other people present, as it is possible for debris,

including stones, to be discharged from the front and rear of the flail head.

Never operate the machine until you have read and understood the relevant

Handbook and are familiar with the controls.

Never use a machine that is poorly maintained or has guards that are damaged

or missing

Never allow an inexperienced person to operate the machine without supervision.

Never use or fit a machine onto a tractor if it doesn’t meet the manufacturer’s

specification.

Never use a machine if the hydraulic system shows signs of damage.

Never attempt to detect a hydraulic leak with your hand, use a piece of card.

Never allow children to play on or around the machine at any time.

Never attempt any maintenance or adjustment without first disengaging the PTO,

lowering the head to the ground, stopping the tractor engine and applying the

tractor parking brake.

Never leave the cab without removing the ignition key.

Never operate the tractor or any controls from any position other than from the

driving seat.

Never stop the engine with the PTO engaged.

Never operate with flails missing.

Never operate PTO above recommended speed, 540 R.P.M. / 1000 R.P.M. flail

head, 150 R.P.M. cutter-bars.

Never operate with wire around the rotor. Stop immediately.

Never use the head at an angle, which may throw debris towards the cab.

Never attempt to use the machine for any purpose other than that it was designed

for.

Never transport with the PTO engaged

Never enter the working area of the machine (risk of injury!)

Never transport with the controls live, always turn off electrical isolator switch

(red) and disconnect supply.