tirak™

G920.3 - 02/2011 EN-DE-FR-NL–V

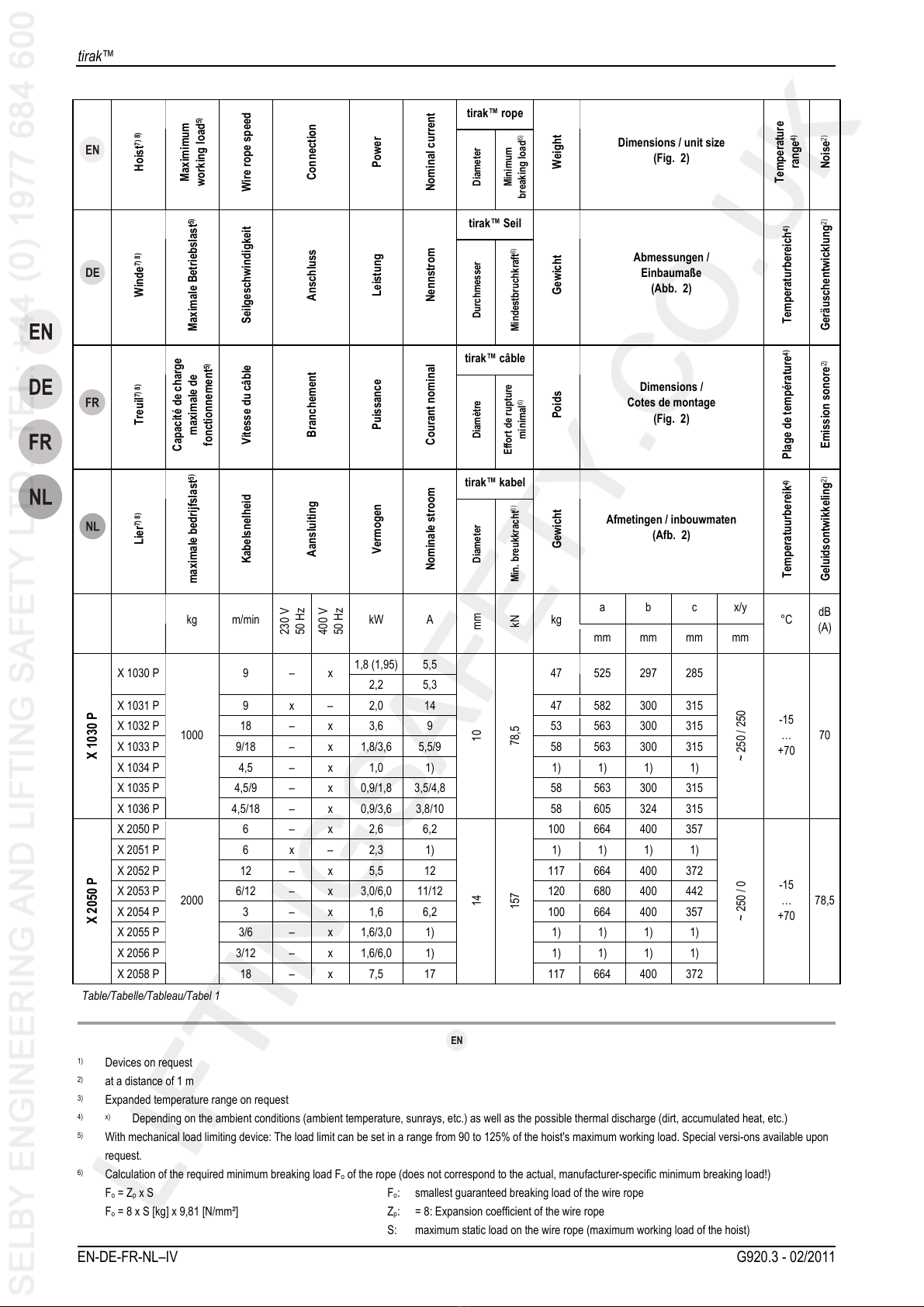

7) In accordance with DIN 15020 the devices correspond to drive group 1 Bmat rope speeds of up to 9 m/min, and to drive group 1 Cmat a rope speed exceeding 9

m/min. The average operating time per day with relation to a year (operating time class) depends on the actual load (load spectrum).

8) Optional for manual emergency operation with hand crank

1) Geräte auf Anfrage

2) in 1 m Abstand

3) erweiterter Temperaturbereich auf Anfrage

4) Abhängig von den Umgebungsbedingungen (Umgebungstemperatur, Sonneneinstrahlung, etc.) sowie der möglichen Wärmeabfuhr (Schmutz, Stauwärme, etc.)

5) Mit mechanischer Hubkraftbegrenzung: Die Hubkraftbegrenzung kann im Bereich von 90 bis 125% der maximalen Betriebslast der Winde eingestellt werden.

Sonderausführungen auf Anfrage.

6) Berechnung der erforderlichen Mindestbruchkraft Fodes Seiles (entspricht nicht der tatsächlichen, herstellerspezifischen Mindestbruchkraft!)

F

o= Zpx S

F

o= 8 x S [kg] x 9,81 [N/mm²]

Fo: kleinste garantierte Bruchlast des Drahtseils

Zp: = 8: Ausnutzungskoeffizient des Drahtseils

S: maximale statische Zuglast im Drahtseil (maximale Betriebslast der Winde)

7) Geräte entsprechen gemäß DIN 15020 bei Seilgeschwindigkeiten bis 9 m/min der Triebwerksgruppe 1 Bm, über 9 m/min Seilgeschwindigkeit der

Triebwerksgruppe 1 Cm. Die mittlere Laufzeit je Tag bezogen auf ein Jahr (Laufzeitklasse) ist abhängig von der tatsächlich auftretenden Belastung (Lastkollektiv).

8) Optional für manuellen Not-Betrieb mit Handkurbel

1) Appareils sur demande

2) A une distance de 1 m

3) Extension de la plage de température sur demande

4) En fonction des conditions ambiantes (température ambiante, exposition à la lumière du soleil, etc.) et de l'évacuation de la chaleur possible sur le site (saleté,

accumulation de chaleur, etc.)

5) Avec limitation mécanique de la force de levage : La force de levage peut être limitée sur une plage de 90 à 125% de la capacité de charge maximale de

fonctionnement du treuil. Modèles spéciaux sur demande.

6) Calcul de l’effort de rupture mininal requis Fodu câble (ne correspond pas à l’effort de rupture minimal effectif et spécifique du fabricant!) :

F

o= Zpx S

F

o= 8 x S [kg] x 9,81 [N/mm²]

Fo: Charge de rupture minimale garantie du câble métallique

Zp: = 8: Coefficient d’utilisation du câble métallique

S: Charge statique maximale du câble métallique (capacité de charge maximale de

fonctionnement du treuil)

7) Appareils conformément à DIN 15020 pour les vitesses de défilement du câble jusqu'à 9 m/min dans la catégorie de mécanismes de treuil 1 Bm, vitesse de

défilement du câble supérieure à 9 m/min dans la catégorie de mécanismes de treuil 1 Cm. La durée de vie moyenne par jour rapportée à un an (classe de durée

de vie) est fonction de la charge réelle sur le câble (spectre de charge).

8) En option pour le mode de secours manuel avec la manivelle à main.

1) Apparaten op aanvraag

2) op 1 m afstand

3) uitgebreid temperatuurbereik op aanvraag

4) Afhankelijk van de omgevingsfactoren (omgevingstemperatuur, zonnestraling etc.) en van de mogelijke warmteafvoer (vuil, warmtestuwing etc.).

5) Met mechanische hefkrachtbegrenzing: De hefkrachtbegrenzing kan worden ingesteld in een bereik van 90 tot 125% van de maximale bedrijfslast van de lier.

Speciale uitvoeringen op aanvraag.

6) Berekening van de minimum breukkracht Fovan de kabel (komt niet overeen met de daadwerkelijke fabrikantspecifieke min. breukkracht!)

F

o= Zpx S

F

o= 8 x S [kg] x 9,81 [N/mm²]

Fo: kleinste gegarandeerde breuklast van de draadkabel

Zp: = 8: Belastingscoëfficiënt van de draadkabel

S: maximale statische treklast in draadkabel (maximale bedrijfslast van de lier)

7) Apparaten voldoen volgens DIN 15020 bij kabelsnelheden tot 9 m/min aan de eisen van de drijfwerkgroep 1 Bm, boven 9 m/min kabelsnelheid aan de eisen van

drijfwerkgroep 1 Cm. De gemiddelde looptijd per dag gerelateerd aan een jaar (looptijdklasse) is afhankelijk van de daadwerkelijk optredende belasting (collectieve

belasting)

8) Optioneel voor handmatige noodwerking met handkruk