GENERAL INFORMATIONS

The EFESTO4 light curtain is a optoelectronic system with multi beams ( Electro-Sensitive Protective

Equipment ) type 4 for the protection of body to prevent accident on the machine on dangerous plants

in accordance with International safety standards.

EFESTO4 is formed of an emitter and a receiver unit synchronized through a optic link. The safety out-

put are at solid state with possibility to transform on power with relays inserted on special module.

The wide range of model permit the employ on every field of industrial automation supplying the

protection of the fingers, hand, arm, body, for the movement on dangerous area.

The principal application are presses, robotized areas, highly automated equipment, and many others.

The series EFESTO4 is divided in different models based on the functions implemented.

This system allows the customer to choose the most adequate model of barrier in according to his

requirements. To complete the range are available some interconnection modules to connect the

barrier without to pass to the general panel of machine.

TERMS AND DEFINITIONS

OSSD0 Safety output channel zero.

OSSD1 Safety output channel one.

OSSD STATO ON Condition on which the output permits the flow of current.

OSSD STATO OFF Condition on which the output do not permit the flow of current.

EDM External Device Monitor.

RESET OSSD restart from OFF to ON.

MUTING Temporary suspension of the safety function.

OVERRIDE Manual muting function after a mistake in automatic muting.

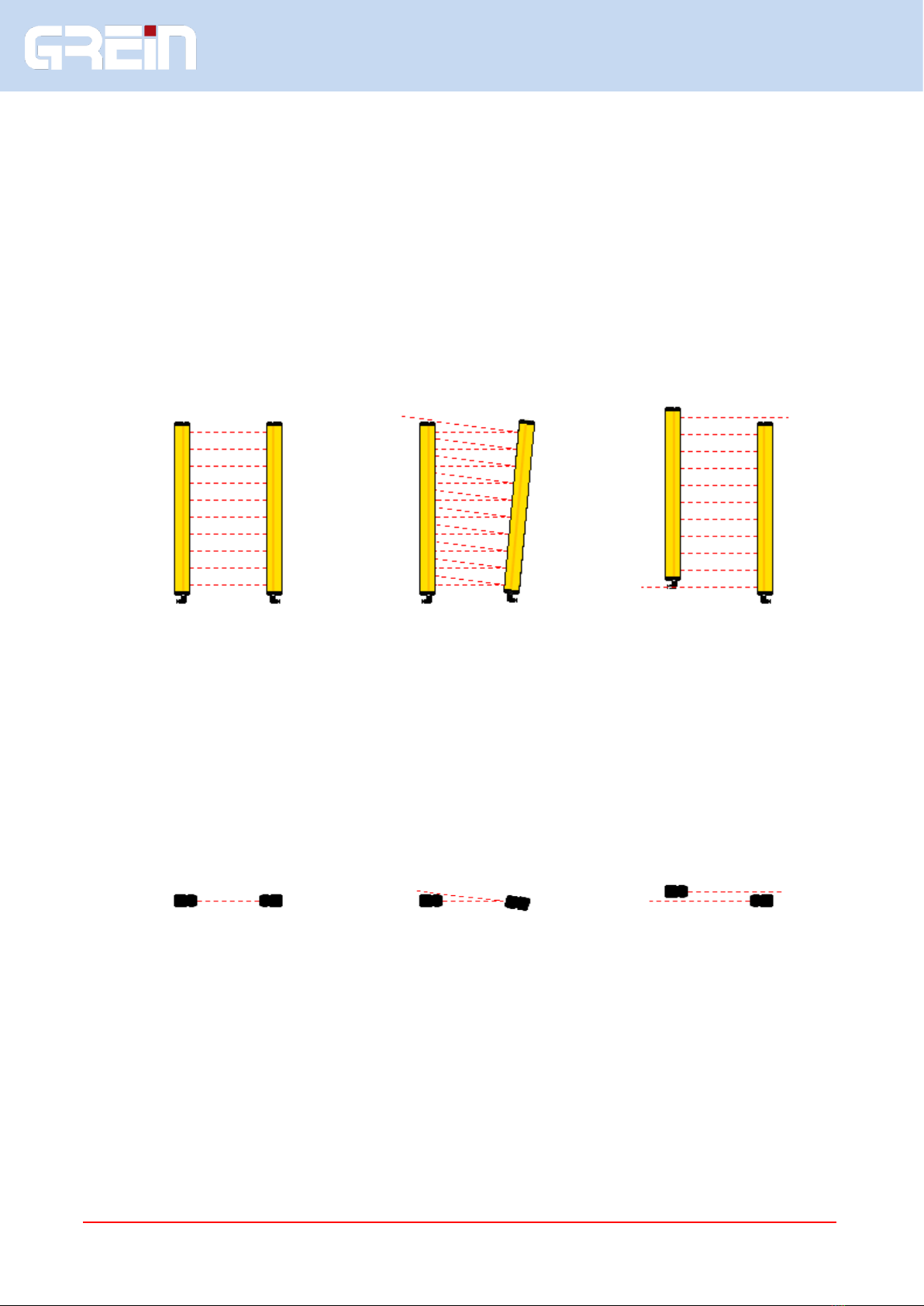

Protective height PH

It is the zone in which the test rod will stop the

barrier.

Sensitive height SH

It is the zone covered by the beams.

AActive part of the lens.

B Beam spacing in mm.

Resolution d

It is the minimum object detected on protected

area, Is the dimension necessary for the

obscuration of two adjacent beams.

d = A + B.