H57.0.1X.6C-03 Operating Manual MSD … - ex page 2 of 8

Content

1GENERAL...............................................................................................................................................................2

2SAFETY...................................................................................................................................................................2

2.1 INTENDED USE ...................................................................................................................................................2

2.2 SAFETY SIGNS AND SYMBOLS ..............................................................................................................................2

2.3 SKILLED PERSONNEL...........................................................................................................................................3

2.4 SAFETY GUIDELINES............................................................................................................................................3

3PRODUCT DESCRIPTION.....................................................................................................................................4

3.1 MOUNTING DESCRIPTION.....................................................................................................................................4

3.2 IDENTIFICATION ..................................................................................................................................................4

3.3 OPERATING AND MAINTENANCE ADVICE...............................................................................................................4

4SPECIFICATION.....................................................................................................................................................5

4.1 SPECIFICATION (MSD …BAE -EX):....................................................................................................................5

4.2 SPECIFICATION (MSD …..RE -EX):....................................................................................................................5

4.3 COMMON SPECIFICATIONS (MSD …BAE -EX,MSD …..RE -EX): ......................................................................5

4.4 ATEX:...............................................................................................................................................................6

5RESHIPMENT AND DISPOSAL.............................................................................................................................6

5.1 RESHIPMENT......................................................................................................................................................6

5.2 DISPOSAL INSTRUCTIONS....................................................................................................................................6

6ADDENDUM 1: EC-TYPE-EXAMINATION CERTIFICATE ..................................................................................6

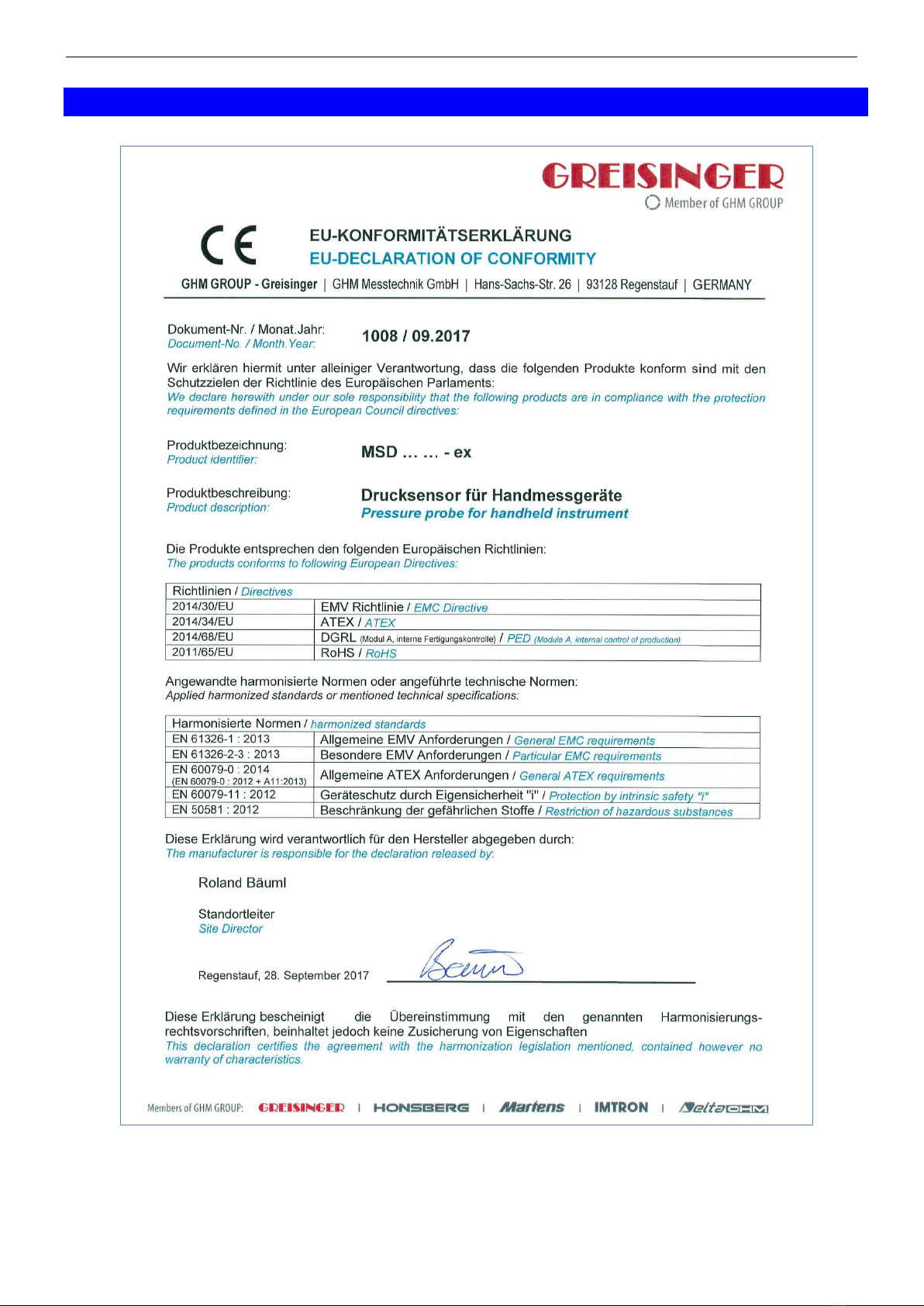

7ADDENDUM 1: EU - DECLARATION OF CONFORMITY ...................................................................................8

1 General

Read through this document attentively and make yourself familiar to the of the device before you use it.

Keep this document in a ready-to-hand way in order to be able to look up in the case of doubt.

2 Safety

2.1 Intended Use

The pressure sensors are designed for the connection to an hand-held instrument of the following types:

GMH 3111 - ex, GMH 3151 - ex, GMH 3156 - ex

The sensors have following application areas:

•air, aggressive gases

•aggressive media, water, etc.

2.2 Safety signs and symbols

Warnings are labelled in this document with the followings signs: