netvox R718VA User manual

Wireless Capacitive Proximity Sensor

R718VA

Wireless Capacitive Proximity Sensor

R718VA

User Manual

Copyright© Netvox Technology Co., Ltd.

This document contains proprietary technical information which is the property of NETVOX Technology. It shall be maintained in strict

confidence and shall not be disclosed to other parties, in whole or in part, without written permission of NETVOX Technology. The

specifications are subject to change without prior notice

1

Table of Contents

1.

Introduction.............................................................................................................................2

2. Appearance...............................................................................................................................3

3. Features....................................................................................................................................3

4. Set up Instruction.....................................................................................................................4

6. Data Report..............................................................................................................................5

6.1 Example of ReportDataCmd..............................................................................................5

6.2 Example for Report Configuration ....................................................................................6

6.3 Example for MinTime/MaxTime logic..............................................................................7

7. Application...............................................................................................................................9

8. Installation................................................................................................................................9

8.1 Measurement and liquid viscosity....................................................................................10

8.2 Containers and installation instruction.............................................................................11

8.3 Adjust sensitivity..............................................................................................................14

9. Information about Battery Passivation...................................................................................15

9.1 To determine whether a battery requires activation .........................................................15

9.2 How to activate the battery ..............................................................................................15

10. Important Maintenance Instruction......................................................................................16

11. Description of Waterproof Grade.........................................................................................16

2

1.

Introduction

R718VA is a device to detect the level of toilet water and liquid hand soap. This device is connected with a non-contact capacitive

sensor can be mounted to the exterior of the container. Without direct contact, the sensor can detect presence and absence of water or

liquid hand soap within the measurement range. The collected data could be transmitted to and displayed by other devices through the

wireless network.

LoRa Wireless Technology:

LoRa is a wireless communication technology dedicated to long distance and low power consumption. Compared with other

communication methods, LoRa spread spectrum modulation method greatly increases to expand the communication distance. Widely

used in long-distance, low-data wireless communications. For example, automatic meter reading, building automation equipment,

wireless security systems, industrial monitoring. Main features include small size, low power consumption, transmission distance,

anti-interference ability and so on.

LoRaWAN:

LoRaWAN uses LoRa technology to define end-to-end standard specifications to ensure interoperability between devices and

gateways from different manufacturers.

3

Function Key

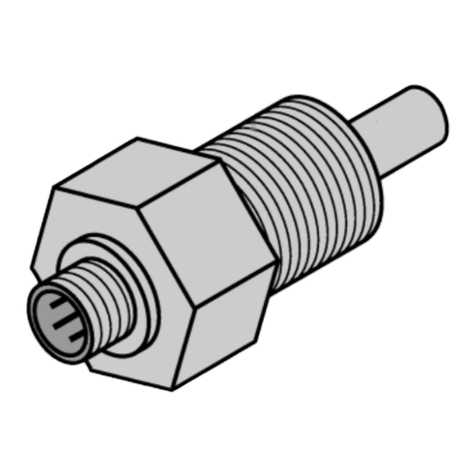

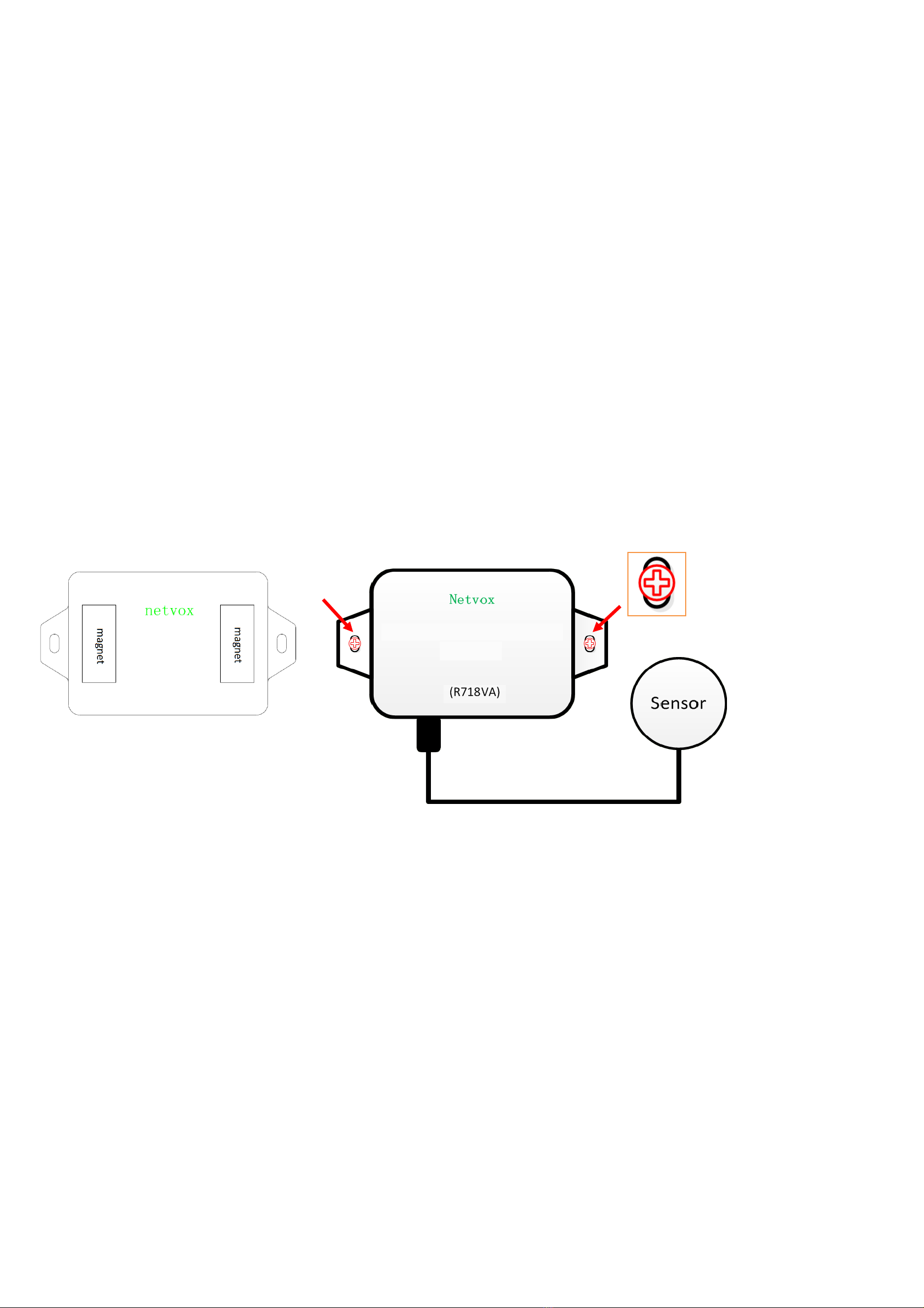

2. Appearance

3. Features

⚫Non-contact capacitive sensor

⚫2 ER14505 battery AA size (3.6V / section) in parallel

⚫Main body: IP65/IP67 (optional); sensor probe: IP67

⚫SX1276 wireless communication module

⚫Magnetic base

⚫LoRaWANTM Class A compatible

⚫Frequency hopping spread spectrum technology

⚫Configure parameters and read data via third-party software platforms; set alarms via SMS and email (optional)

⚫Applicable to third-party platforms: Actility / ThingPark / TTN / MyDevices / Cayenne

⚫Low power consumption and long battery life

Note: Battery life is determined by the sensor reporting frequency and other variables. Please refer to

http://www.netvox.com.tw/electric/electric_calc.html. On this website, users can find various types of battery lifetime in different

configurations.

Indicator

Capacitive Proximity Sensor

4

4. Set up Instruction

On/Off

Power on

Insert batteries. (User may need a screwdriver to open battery cover.)

Turn on

Press and hold the function key for 3 seconds until the green indicator flashes once.

Turn off (factory resetting)

Press and hold the function key for 5 seconds until the green indicator flashes for 20 times.

Power off

Remove Batteries

Note

1. Remove and insert the batteries; the device is at off state by default. Please turn on the

device to use again.

2. On/off interval is suggested to be about 10 seconds to avoid the interference of capacitor

inductance and other energy storage components.

3. At 1st to 5th second after power on, the device will be in engineering test mode.

Network Joining

Never joined the network

Turn on the device to search the network to join.

The green indicator stays on for 5 seconds: Success

The green indicator remains off: Fail

Had joined the network

(Not yet restore to factory setting)

Turn on the device to search the previous network to join.

The green indicator stays on for 5 seconds: Success

The green indicator remains off: Fail

Fail to join the network

(when the device is on)

Suggest to check the device verification information on the gateway or consult your

platform server provider

Function Key

Press and hold for 5 seconds

Restore to factory setting / Turn off

The green indicator flashes for 20 times: Success

The green indicator remains off: Fail

Press once

The device is in the network: the green indicator flashes once and sends a report

The device is not in the network: the green indicator remains off

Sleeping Mode

The device is on and in the

network

Sleeping period: Min Interval.

When the reportchange exceeds setting value or the state changes: send a data report

according to Min Interval.

Low Voltage Warning

Low Voltage

3.2V

5

6. Data Report

The device will immediately send a version packet report along with an uplink packet including liquid level status, battery voltage.

The device sends data in the default configuration before any configuration is done.

Default Setting:

Maximum time: 0x384 (15min)

Minimum time: 0x384 (15min) (detect voltage and liquid level every Min Interval)

BatteryVoltageChange: 0x01 (0.1V)

R718VA detection status:

As the device detects liquid, the device would send a report of current status and battery voltage.

The threshold could be modified through sensitivity adjustment as the distance between liquid and sensor reaches the threshold.

When the device detects liquid level, status = 1; when the device does not detect liquid level, status = 0

Under two conditions, the device will report the status of the detected liquid and the battery voltage at MinTime interval:

a. When the liquid level changes from where the device can detect to where the device cannot detect. (1→0 )

b. When the liquid level changes from where the device cannot detect to where the device can detect. (0→1)

If none of the above conditions is met, the device will report at the MaxTime interval.

For the analysis of the data command reported by the device, refer to the Netvox LoRaWAN Application Command document and

http://www.netvox.com.cn:8888/page/index.

Note: The device sends data cycle depends on real programming configuration according to the customer’s inquiry.

The interval between two reports must be the minimum time.

6.1 Example of ReportDataCmd

FPort: 0x06

Bytes

1

1

1

Var(Fix=8 Bytes)

Version

DeviceType

ReportType

NetvoxPayLoadData

Version–1 byte –0x01——the Version of NetvoxLoRaWAN Application Command Version

DeviceType–1 byte –Device Type of Device

The devicetype is listed in Netvox LoRaWAN Application Devicetype doc

ReportType–1 byte - the presentation of the NetvoxPayLoadData, according the devicetype

NetvoxPayLoadData–Var (Fixed =8bytes)

6

Tips

1. Battery Voltage:

The voltage value is bit 0 ~ bit 6, bit 7=0 is normal voltage, and bit 7=1 is low voltage.

Battery=0xA0, binary=1010 0000, if bit 7= 1, it means low voltage.

The actual voltage is 0010 0000 = 0x20 = 32, 32*0.1v =3.2v

2. Version Packet:

When Report Type=0x00 is the version packet, such as 019F000A02202108130000, the firmware version is 2021.08.13.

2. Data Packet:

When Report Type=0x01 is data packet.

Device

DeviceType

ReportType

NetvoxPayLoadData

R718VA

0x9F

0x00

SoftwareVersion

(1 Byte)

Eg.0x0A-V1.0

HardwareVersion

(1 Byte)

DateCode

(4 Byte)

eg 0x20170503

Reserved

(2 Byte)

0x01

Battery

(1Byte, unit:0.1V)

Status

(1Byte 0:off 1:on)

Reserved

(6Bytes,fixed 0x00)

Example of Uplink: 019F012400000000000000

1st byte (01): Version

2nd byte (9F): DeviceType 0x9F-R718VA

3rd byte (01): ReportType

4th byte (24): Battery-3.6v 24 Hex=36 Dec 36*0.1v=3.6v

5th byte (00): Status

6th-11th byte (000000000000): Reserved

6.2 Example for Report Configuration

Fport: 0x07

Bytes

1

1

Var(Fix=9 Bytes)

CmdID

DeviceType

NetvoxPayLoadData

CmdID–1 byte

DeviceType–1 byte –Device Type of Device

NetvoxPayLoadData–var bytes (Max=9bytes)

7

(1) Configure the device report parameters MinTime = 1min (003C), MaxTime = 1min (003C), BatteryChange = 0.1v (0x01)

Downlink: 019F003C003C0100000000

The device returns:

819F000000000000000000 (configuration succeeded)

819F010000000000000000 (configuration failed)

(2) Read the device configuration parameters

Downlink: 029F000000000000000000

The device returns:

829F003C003C0100000000 (current configuration parameters)

6.3 Example for MinTime/MaxTime logic

Example#1 based on MinTime = 1 Hour, MaxTime= 1 Hour, Reportable Change i.e. BatteryVoltageChange=0.1V

MaxTime MaxTime

sleeping (MinTime) Sleeping (MinTime)

Note: MaxTime=MinTime. Data will only be report according to MaxTime (MinTime) duration regardless BatteryVoltageChange

value.

Description

Device

CmdID

Device

Type

NetvoxPayLoadData

ConfigReportReq

R718VA

0x01

0x9F

MinTime

(2bytes Unit:s)

MaxTime

(2bytes Unit:s)

BatteryChange

(1byte

Unit:0.1v)

Reserved

(4Bytes,Fixed

0x00)

ConfigReportRsp

0x81

Status

(0x00_success)

Reserved

(8Bytes,Fixed 0x00)

ReadConfigReportReq

0x02

Reserved

(9Bytes,Fixed 0x00)

ReadConfigReportRsp

0x82

MinTime

(2bytes Unit:s)

MaxTime

(2bytes Unit:s)

BatteryChange

(1byte

Unit:0.1v)

Reserved

(4Bytes,

Fixed 0x00)

Wake up and collects data

REPORTS 3.6V

Wakes up and collects data

REPORTS 3.6V

Wakes up and collects data

REPORTS 3.6V

8

Example#2 based on MinTime = 15 Minutes, MaxTime= 1 Hour, Reportable Change i.e. BatteryVoltageChange= 0.1V.

MaxTime

sleeping (MinTime) sleeping sleeping sleeping

0H 15th M 30th M 45th M 1H 2H

Example#3 based on MinTime = 15 Minutes, MaxTime= 1 Hour, Reportable Change i.e. BatteryVoltageChange= 0.1V.

MaxTime

sleeping sleeping ...

0H 15th M 30th M 45th M 1H 1H 10th M 1H 25th M 1H 40th M 1H 55th M 2H 10th M

Note:

1) The device only wakes up and performs data sampling according to MinTime Interval. When it is sleeping, it does not

collect data.

2) The data collected is compared with the last data reported. If the data variation is greater than the ReportableChange value,

the device reports according to MinTime interval. If the data variation is not greater than the last data reported, the device

reports according to MaxTime interval.

3) We do not recommend to set the MinTime Interval value too low. If the MinTime Interval is too low, the device wakes up

frequently and the battery will be drained soon.

4) Whenever the device sends a report, no matter resulting from data variation, button pushed or MaxTime interval, another

cycle of MinTime/MaxTime calculation is started.

Wakes up and

collects data

3.6V

Does not report

Wakes up and

collects data

3.6V

Does not report

Wakes up and

collects data

3.6V

Does not report

Wakes up and

collects data

REPORTS 3.6V

Wakes up and

collects data

REPORT 3.6V

Wakes up and

collects data

REPORTS 3.5V

Wakes up and

collects data

REPORTS 3.6V

Wakes up and collects data

3.5V |3.5-3.6|=0.1

REPORTS 3.5V

Wakes up and

collects data

3.5V

Does not report

Wakes up and

collects data

3.5V

Does not report

Wakes up and

collects data

3.5V

Does not report

Wakes up and

collects data 3.5V

Does not report

Wakes up and

collects data

3.5V

Does not report

Wakes up and

collects data

3.6V

Does not report

Users push the button,

REPORTS 3.5V.

Recalculate MaxTime.

9

7. Application

When the device is used to detect the water level of the toilet tank, please install the device at a desired level of the toilet tank.

Turn on the device after it is fixed to the toilet tank and powered. The device will detect the status regularly at the MinTime interval.

There are two conditions in which the device will report the status of the detected liquid and the battery voltage at MinTime interval:

a. When the liquid level changes from where the device can detect to where the device cannot detect

b. When the liquid level changes from where the device cannot detect to where the device can detect

If none of the above conditions is met, the device will report at the MaxTime interval.

8. Installation

Wireless Capacitive Proximity Sensor (R718VA) has two magnets on the back. When using it, the back can attach to a ferromagnetic

material, or the two ends can be fixed to the wall with screws (that purchased by users).

Note:

Do not install the device in a metal shielded box or around electrical equipment or it may affect the wireless transmission of the device.

Fixed with screws

10

8.1 Measurement and liquid viscosity

8.1.1 What is dynamic viscosity?

Dynamic viscosity is the tangential force per unit area required to move one horizontal plane with respect to another plane - at

an unit velocity - when maintaining an unit distance apart in the fluid.

8.1.2 Dynamic viscosity

A.< 10mPa·s (the liquid can be measured)

B. 10mPa·s < Dynamic viscosity < 30mPa·s (the results may be affected)

C. > 30mPa·s (cannot be measured due to a large amount of liquid attached to the container wall)

Note: The viscosity decreases as the temperature rises.

Liquid with high viscosity is easily affected by temperature. To get accurate result, please mind the liquid temperature while

measuring.

8.1.3 Common substances

Substance

Viscosity (mPa·s)

Temperature (°C)

Benzene

0.604

25

Water

1.0016

20

Mercury

1.526

25

Whole milk

2.12

20

Olive oil

56.2

26

Reference source: https://en.wikipedia.org/wiki/Viscosity

11

8.2 Containers and installation instruction

1. Fix the probe by glue and tapes or held by tiny shelf on the outside of the container.

2. Avoid metal materials around the probe to get accurate result.

3. The place where the probe is installed should avoid the liquid and the flow path of the liquid.

4. There should be no silt or other debris inside the container where the lower probe is directly facing, so as not to affect the

detection.

8.2.1 Insulation Materials

Containers made of non-metallic materials with flat surface, uniform thickness, tight material and good insulation

performance; such as glass, plastic, non-absorbent ceramic, acrylic, rubber and other materials or their composite materials.

Cautions:

1. If the wall of the container where the measuring probe is installed is a multi-layer material, the layers should be in close

contact without bubbles or gas inter-layers. The inside and outside surfaces of the container should be flat.

2. The thickness of container: 0 to 20mm

3. Tank type: spherical tank, horizontal tank, vertical tank, etc.

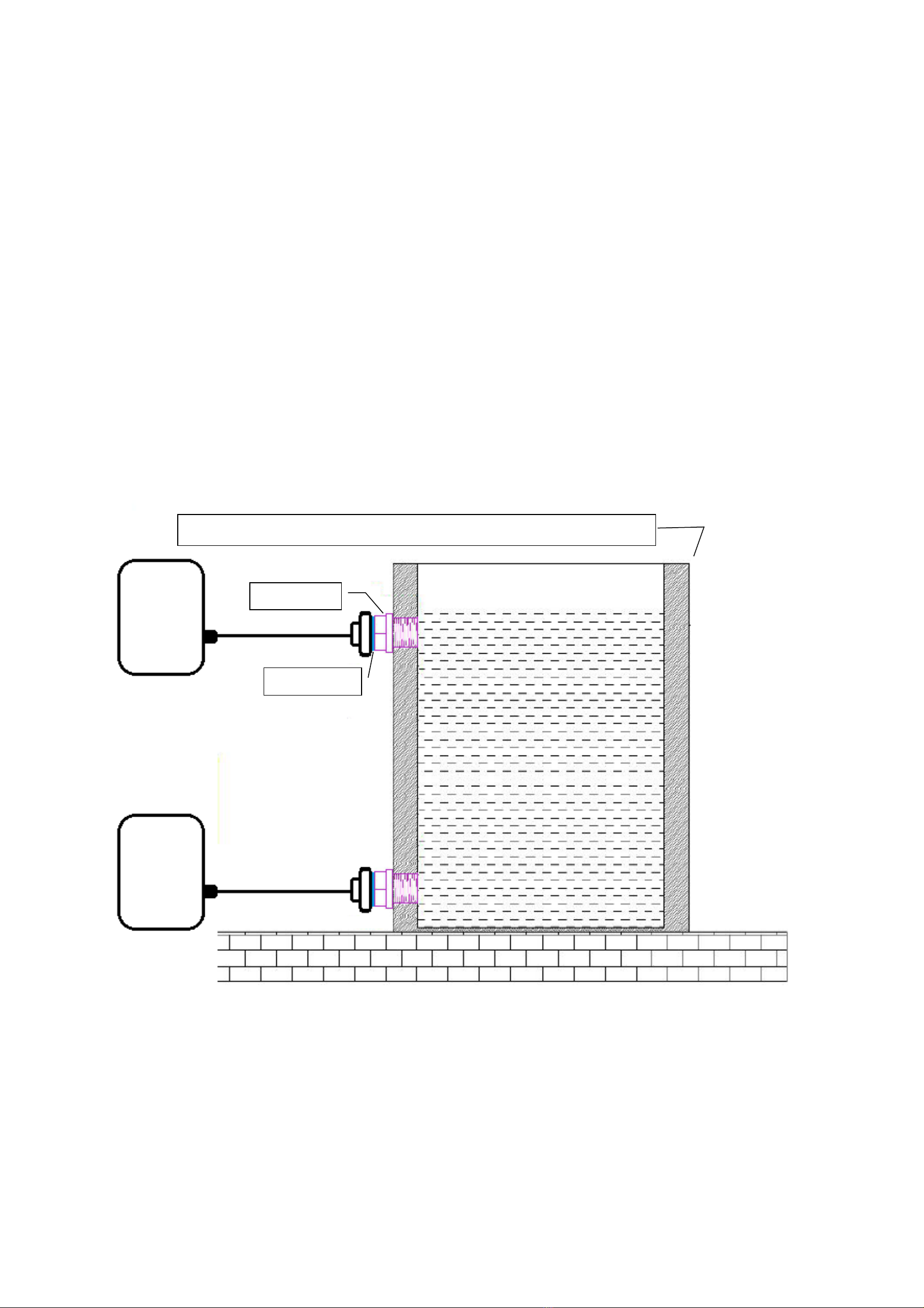

Figure 1. Sensor installation for non-metallic containers

R718VA

R718VA

Plastic, glass, ceramics, etc. non-metallic container

Mucilage glue

12

8.2.2 Metallic container

Containers made of metal or other conductive materials; such as stainless steel iron, copper, aluminum alloy or materials with

electroplated metal layer on the surface. Because the capacitive sensor is sensitive to all conductive objects, sensor cannot be

glued on the outside of the container. Therefore, users should drill holes on the container so as to install the sensor.

Installation method:

1. Prepare 2 rubber plugs and tools for drilling.

2. Open one hole in the high position and one in low position, the hole diameter have to match the size of the rubber plug.

3. Put the rubber plug into the holes and check if there is water leakage. Add glue to seal the holes if necessary.

4. Glue the sensor on the rubber plug with glue and fix it with a tiny shelf. Make sure the glue has solidified before removing

the shelf.

Figure 2. Sensor installation for metallic container

R718VA

R718VA

Mucilage glue

Rubber plug

Copper, iron, stainless steel metal material water tower, boiler etc. metallic container

13

8.2.3. Water-absorbing container

Containers made of ceramics, tiles, bricks, tiles, cement, wooden boards and other materials are insulators or weakly

conductive. Without water or under dry condition, the container may not be detected when the water level sensor is

approached. However, when the water is filled in the container, the wall will absorb water thus causing the container wall to

become a conductor. In this case, even if the water is out of the container, the sensor will still detect when the sensor

approaches the wall of the container. If user would like to use water-absorbing containers, the installation method should

follow as the same as the metallic containers’or install external pipes as below (figure 3 and 4).

Figure 3.Sensor installation on the branch tee outlet

Figure 4. Sensor glued on the outside of the external pipeline

R718VA

R718VA

Mucilage

glue

Rubber plug

Branch tee outlet

R718VA

R718VA

Mucilage

glue

Rubber

pipeline

14

Figure 5. Sensor installed on the branch tee outlet of metal water pipes

Figure 6. Sensor attached to the rubber tube

8.3 Adjust sensitivity

1. Open the back cover of the sensor head.

2. Adjust the sensitivity knob with a small screwdriver.

3. Rotate counterclockwise to increase the sensitivity or clockwise to

decrease the sensitivity

(sensitivity from high to low: 12 circles in total)

Mucilage glue

Rubber tube

R718VA

R718VA

Mucilage glue

Rubber plug

Metal water pipe

15

9. Information about Battery Passivation

Many of Netvox devices are powered by 3.6V ER14505 Li-SOCl2 (lithium-thionyl chloride) batteries that offer many

advantages including low self-discharge rate and high energy density. However, primary lithium batteries like Li-SOCl2 batteries

will form a passivation layer as a reaction between the lithium anode and thionyl chloride if they are in storage for a long time or if

the storage temperature is too high. This lithium chloride layer prevents rapid self-discharge caused by continuous reaction between

lithium and thionyl chloride, but battery passivation may also lead to voltage delay when the batteries are put into operation, and our

devices may not work correctly in this situation.

As a result, please make sure to source batteries from reliable vendors, and it is suggested that if the storage period is more than

one month from the date of battery production, all the batteries should be activated. If encountering the situation of battery

passivation, users can activate the battery to eliminate the battery hysteresis.

ER14505 Battery Passivation

9.1 To determine whether a battery requires activation

Connect a new ER14505 battery to a resistor in parallel, and check the voltage of the circuit.

If the voltage is below 3.3V, it means the battery requires activation.

9.2 How to activate the battery

a. Connect a battery to a resistor in parallel

b. Keep the connection for 5~8 minutes

c. The voltage of the circuit should be ≧3.3, indicating successful activation.

Brand

Load Resistance

Activation Time

Activation Current

NHTONE

165 Ω

5 minutes

20mA

RAMWAY

67 Ω

8 minutes

50mA

EVE

67 Ω

8 minutes

50mA

SAFT

67 Ω

8 minutes

50mA

Note: If you buy batteries from other than the above four manufacturers, then the battery activation time, activation current, and

required load resistance shall be mainly subject to the announcement of each manufacturer.

16

10. Important Maintenance Instruction

Kindly pay attention to the following in order to achieve the best maintenance of the product:

• Keep the device dry. Rain, moisture, or any liquid might contain minerals and thus corrode electronic circuits. If the device gets

wet, please dry it completely.

• Do not use or store the device in dusty or dirty environment. It might damage its detachable parts and electronic components.

• Do not store the device under excessively hot condition. High temperatures can shorten the life of electronic devices, destroy

batteries, and deform or melt some plastic parts.

• Do not store the device in places that are too cold. Otherwise, when the temperature rises to normal temperature, moisture will

form inside, which will destroy the board.

• Do not throw, knock or shake the device. Rough handling of equipment can destroy internal circuit boards and delicate

structures.

• Do not clean the device with strong chemicals or detergents.

• Do not apply the device with paint. Smudges might block the device and affect the operation.

• Do not throw the battery into the fire, or the battery will explode. Damaged batteries may also explode.

All of the above applies to your device, battery, and accessories. If any device is not working properly, please take it to the nearest

authorized service facility for repair.

11. Description of Waterproof Grade

1. According to Enclosure Protection Class, this standard is equivalent to IEC 60529:2001 Degrees of Protection Provided by

Enclosures (IP Code).

2. The test method of IP65 waterproof grade is: spray the device in all directions under 12.5L/min water flow for 3min, and the

internal electronic function is normal.

The test method of IP67 waterproof grade is: the device is immersed in 1m deep water for 30min, and the internal electronic

function is normal.

IP65 is dust-proof and able to prevent damage caused by water from nozzles in all directions from invading electrical appliances. It

can be used in general indoor environments and sheltered outdoor environments. It is not suitable to be used in environments with

high water pressure, high temperature, high humidity, or long-time exposure to sunlight and rainstorm. If it is really necessary to

install in harsh environments, it is recommended to add rain and sun shields.

Figure 1. Install the device upside down.

Figure 2. Install the device under the rain/sun shield.

Other manuals for R718VA

1

Table of contents

Other netvox Accessories manuals

netvox

netvox R718EA User manual

netvox

netvox R313WA User manual

netvox

netvox R718PB15 User manual

netvox

netvox RA0716A User manual

netvox

netvox R72616A User manual

netvox

netvox R313FA1 User manual

netvox

netvox R72632A01 User manual

netvox

netvox R312 User manual

netvox

netvox RA0701 User manual

netvox

netvox R718G User manual

netvox

netvox ZigBee Z801WLS User manual

netvox

netvox R311FD User manual

netvox

netvox R711 User manual

netvox

netvox R311FA1 User manual

netvox

netvox RA0708 User manual

netvox

netvox R313B User manual

netvox

netvox R718G User manual

netvox

netvox R718AD User manual

netvox

netvox R718PE01 User manual

netvox

netvox R313DA User manual