E32.0.05.6C-07 Mounting and operating manual GIR 2000 Pt page 2 of 18

Contents

1. SAFETY ....................................................................................................................................................... 3

1.1. General note............................................................................................................................................ 3

1.2. Intended use............................................................................................................................................ 3

1.3. Skilled personnel..................................................................................................................................... 3

1.4. Type label ............................................................................................................................................... 4

1.5. Safety signs and symbols........................................................................................................................ 4

1.6. Reasonably foreseeable misuse............................................................................................................... 5

1.7. Safety guidelines..................................................................................................................................... 5

2. PRODUCT DESCRIPTION....................................................................................................................... 5

2.1. Scope of supply....................................................................................................................................... 5

2.2. Function .................................................................................................................................................. 6

3. MOUNTING IN PANELS / HOUINGS.................................................................................................... 6

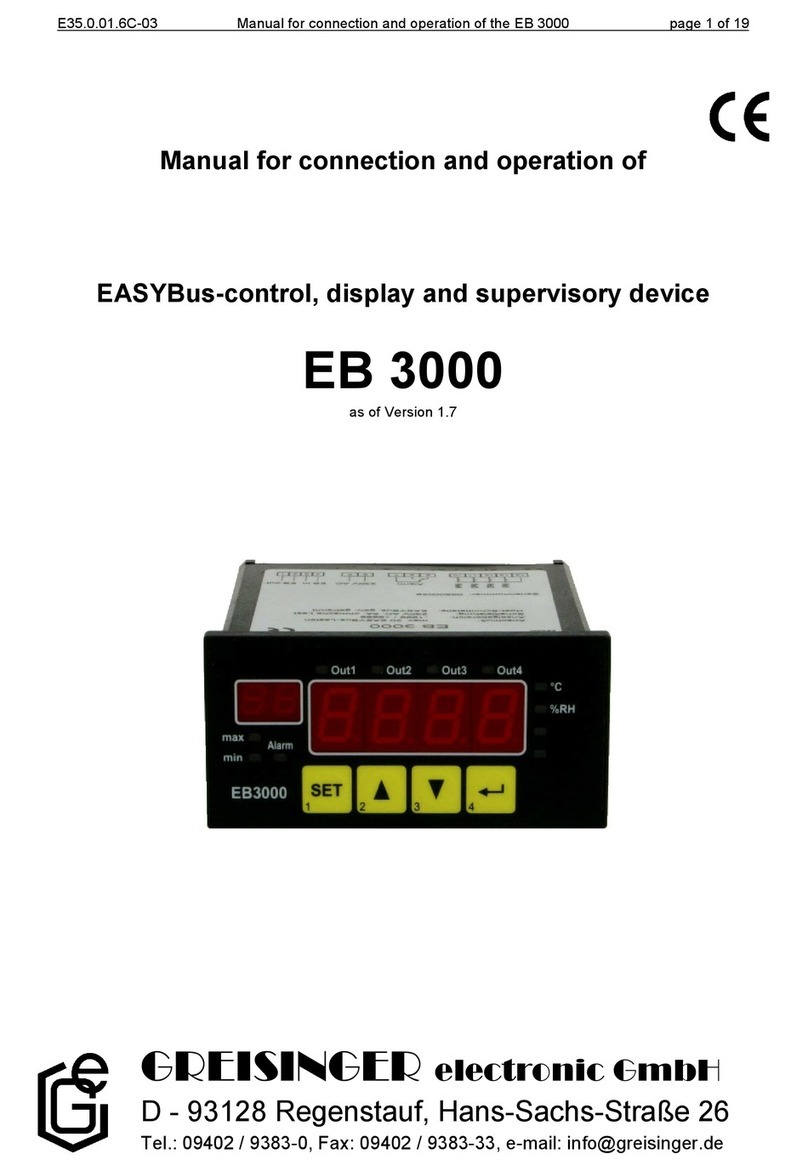

4. DISPLAY AND OPERATING ELEMENTS............................................................................................ 6

4.1. Display elements..................................................................................................................................... 7

4.2. Operating elements ................................................................................................................................. 7

5. ELECTRIC CONNECTION...................................................................................................................... 8

5.1. Terminal assignment: Standard............................................................................................................... 8

5.2. Connection data ...................................................................................................................................... 8

5.3. Connecting an input signal...................................................................................................................... 8

5.4. Connecting switching outputs................................................................................................................. 9

6. CONFIGURATION OF THE MEASURING INPUT............................................................................. 9

6.1. Configuration: select filter.................................................................................................................... 10

7. CONFIGURATION OF THE OUTPUT FUNCTIONS........................................................................ 10

7.1. Selection of the output function............................................................................................................ 11

7.2. 2-point-controller.................................................................................................................................. 11

7.3. Min-/Max-Alarm................................................................................................................................... 11

8. OFFSET- AND SLOPE-ADJUSTMENT................................................................................................ 12

8.1. Menu calling and adjustment................................................................................................................ 13

9. SWITCHING POINTS AND ALARM-BOUNDARIES........................................................................ 13

9.1. Menu calling......................................................................................................................................... 14

9.2. 2-point-controller.................................................................................................................................. 14

9.3. Minimum/maximum-alarm................................................................................................................... 14

10. MIN-/MAX-VALUE MEMORY:.......................................................................................................... 15

11. ALARM DISPLAY ................................................................................................................................. 15

12. ERROR CODES...................................................................................................................................... 16

13. DECOMMISSIONING, RESHIPMENT AND DISPOSAL................................................................ 16

13.1. Decommissioning ............................................................................................................................... 16

13.2. Reshipment and disposal..................................................................................................................... 16

14. SPECIFICATION ................................................................................................................................... 17