Page 3

DLT 2.0 Differential Level Transmitter

INDEX

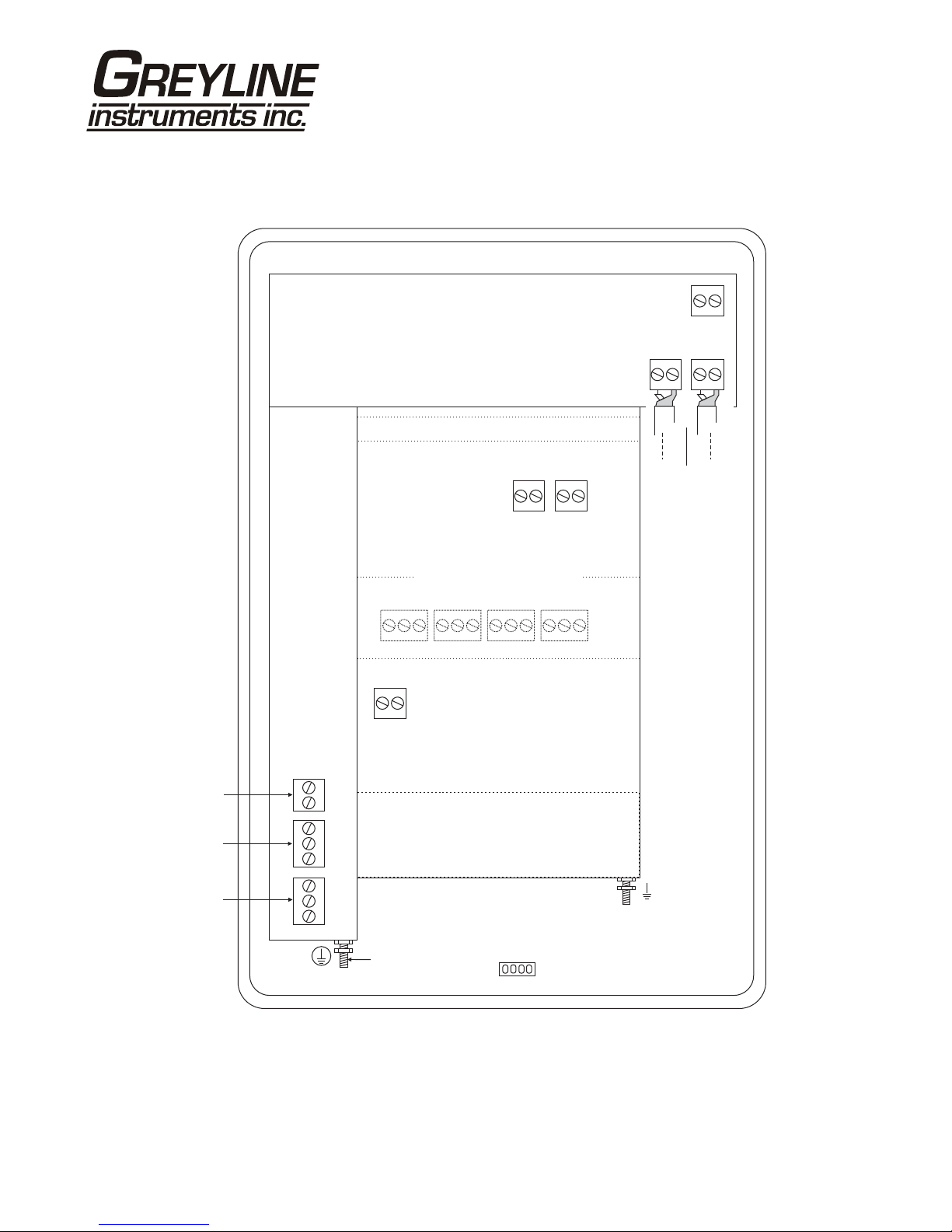

CONNECTIONS: ...............................................................................................4

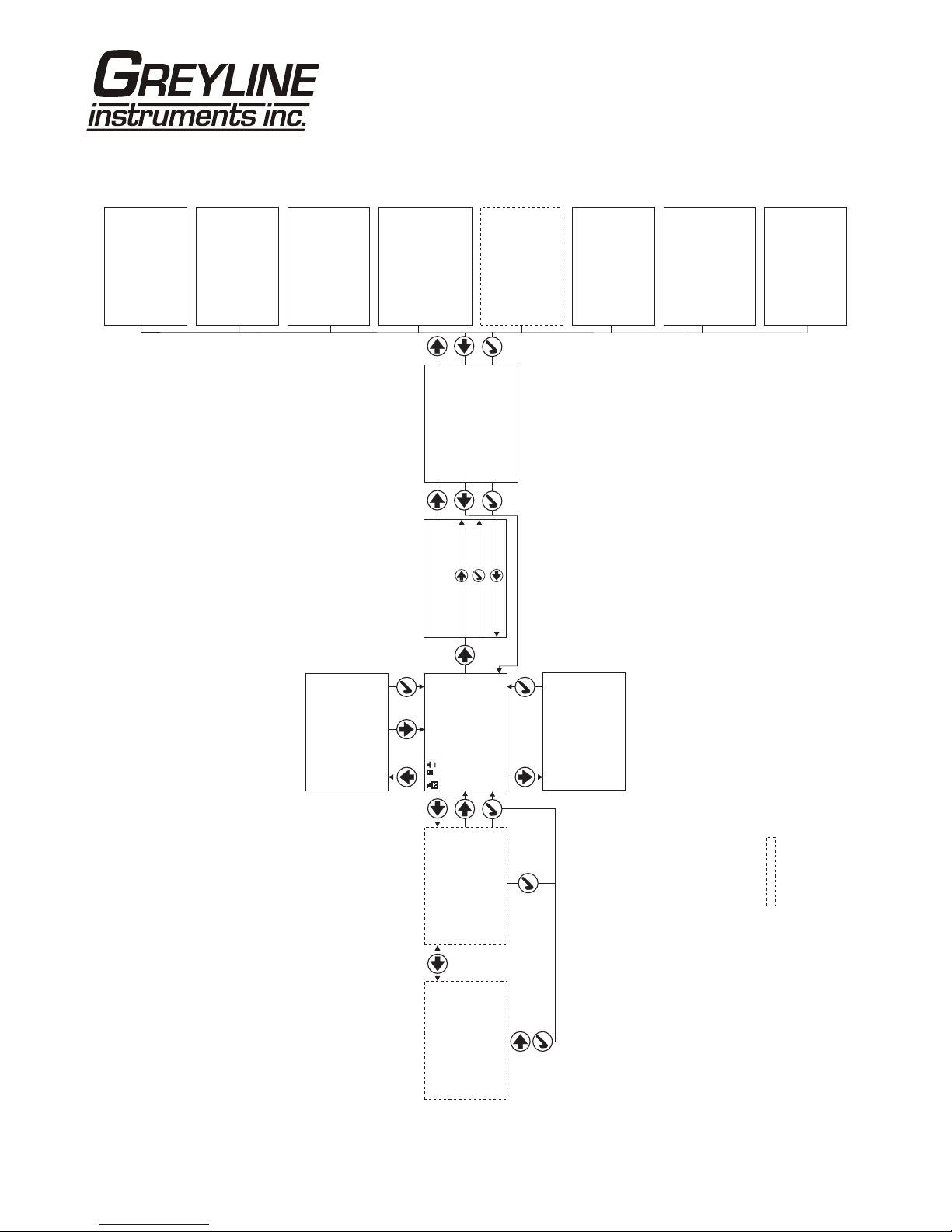

KEYPAD SYSTEM............................................................................................6

CALIBRATION MENU.....................................................................................7

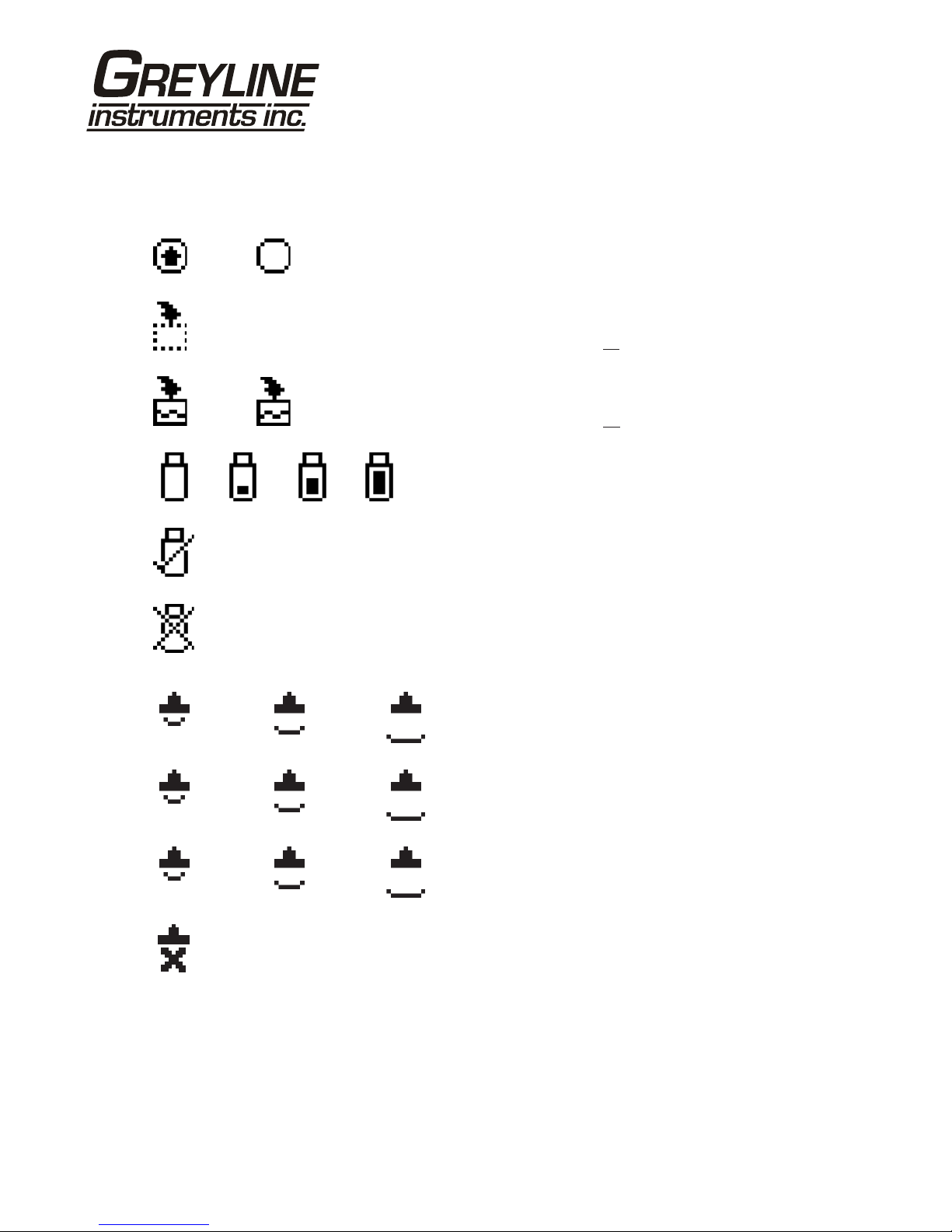

ICONS.................................................................................................................8

MAIN DISPLAY................................................................................................9

MESSAGE ICON...............................................................................................9

STATUS .............................................................................................................9

PASSWORD.....................................................................................................10

UNITS/MODE..................................................................................................11

CALIBRATION................................................................................................12

CHANNEL SETUP ..........................................................................................16

RELAY PARAMETERS..................................................................................17

SPECIAL FUNCTIONS...................................................................................18

SENSOR MOUNTING/LOCATION...............................................................20

APPLICATIONS HOTLINE............................................................................26

PRODUCT RETURN PROCEDURE..............................................................27

APPENDIX A - OPTIONS...............................................................................29

DATA LOGGING (Optional)...........................................................................35

CONVERSION GUIDE ...................................................................................37

SPECIFICATIONS...........................................................................................38

IMPORTANT NOTE: This instrument is manufactured and calibrated to meet product specifications.

Please read this manual carefully before installation and operation. Any unauthorized repairs or

modifications may result in a suspension of the warranty.

Available in Adobe Acrobat pdf format