4

CONTENTS

SAFETY INSTRUCTIONS ........................................................................................................................................... 2-3

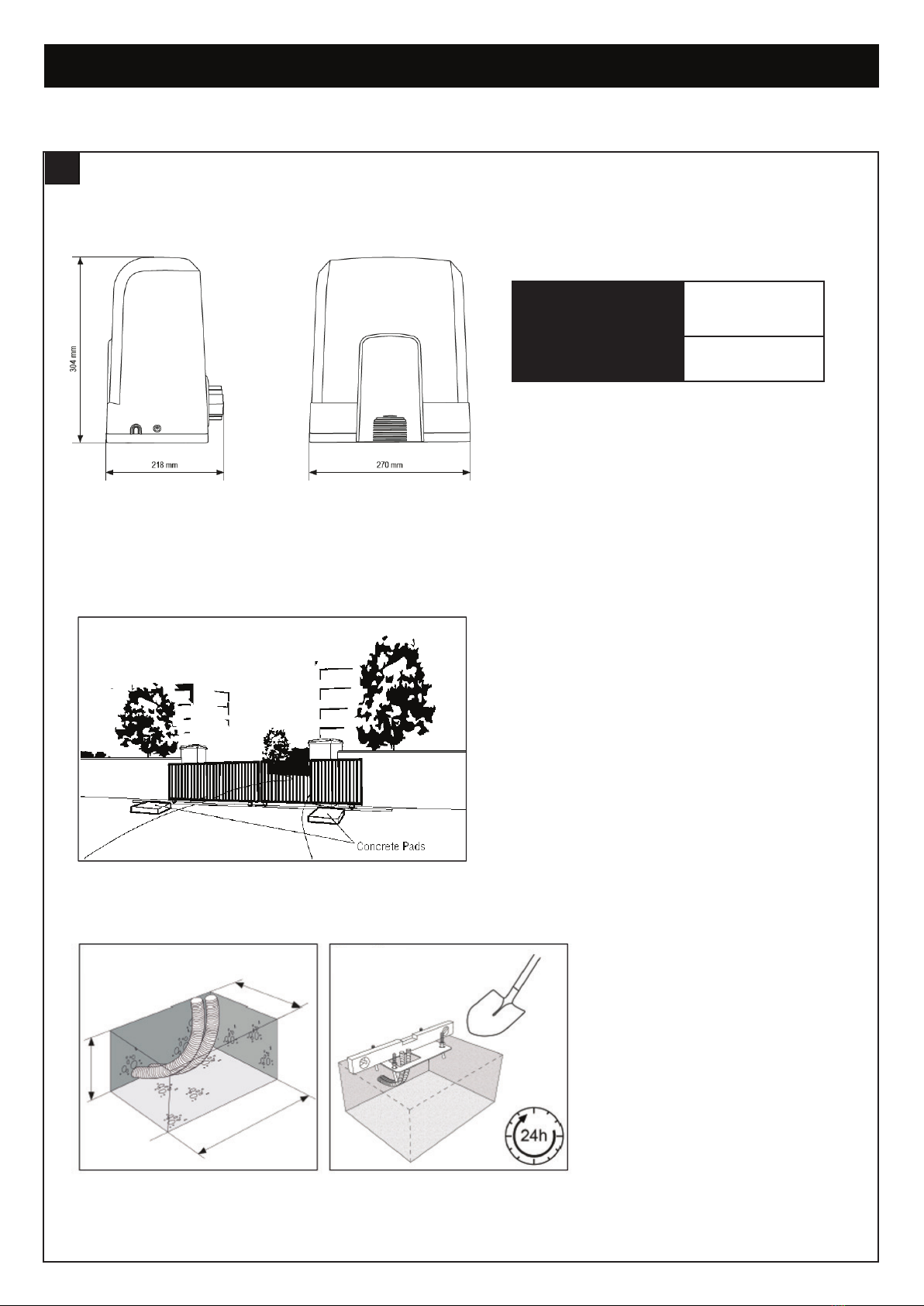

INTRODUCTION ......................................................................................................................................................... 5-7

Specifications .........................................................................................................................................................................................5

Sales Kit Inventory..................................................................................................................................................................................5

Tools Needed.........................................................................................................................................................................................6

Overview of Gate Operator.....................................................................................................................................................................6

Planning ........................................................................................................................................................................................... 7-10

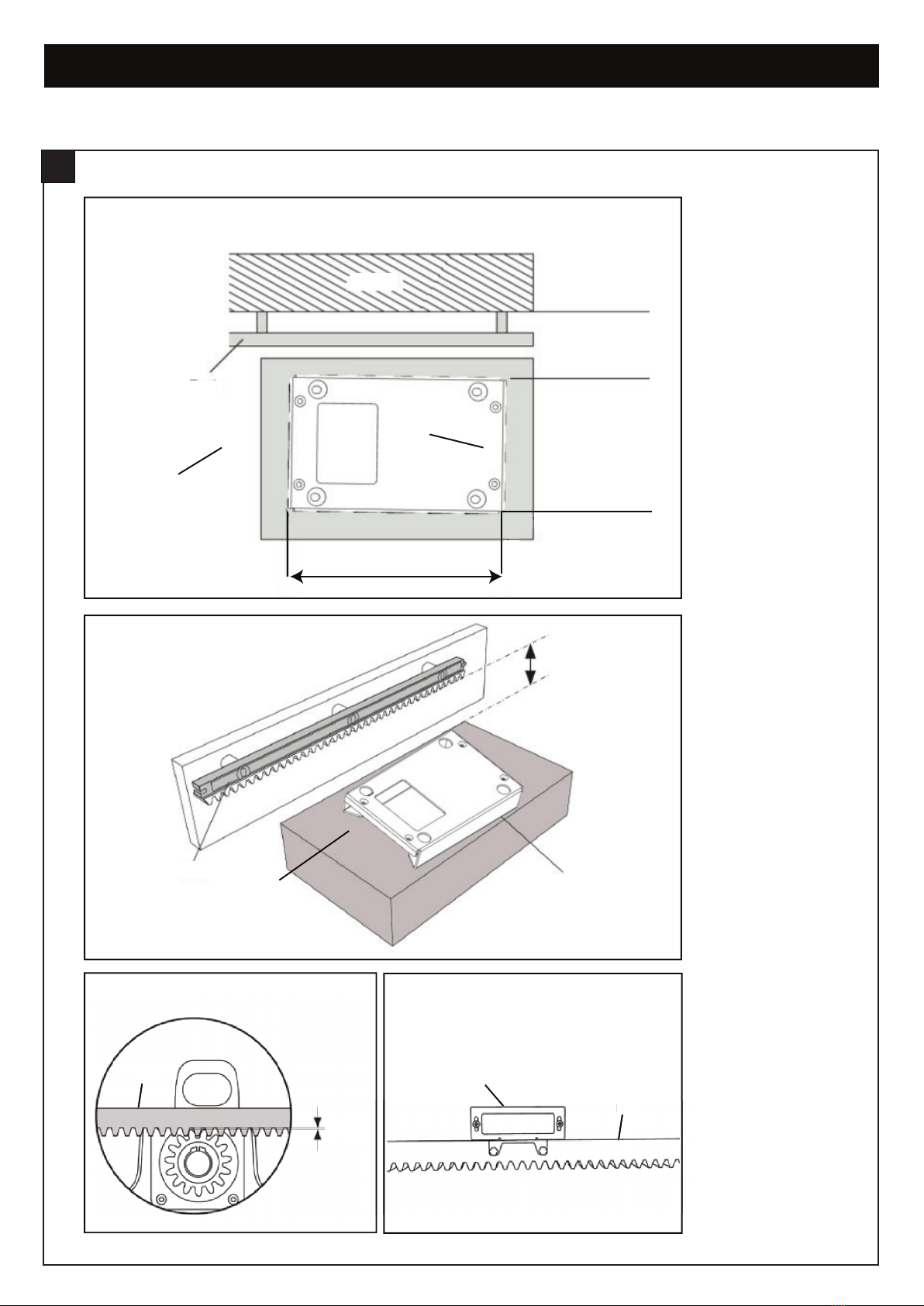

INSTALLATION ....................................................................................................................................................... 11-13

Installing the Base Mounting Plate........................................................................................................................................................11

Disengagement of the Manual Release.................................................................................................................................................11

Installing the Opener on the Base Mounting Plate ................................................................................................................................12

Gate Rack Mounting ............................................................................................................................................................................12

Installing the Limit Switch Brackets ......................................................................................................................................................13

WIRING .................................................................................................................................................................... 14-17

Electrical Safety....................................................................................................................................................................................14

Commissionaing the Gate Opener........................................................................................................................................................14

Access to the Control Board and Motor Connection............................................................................................................................15

Wiring Diagram.....................................................................................................................................................................................16

Install Entrapment Protection Devices ..................................................................................................................................................17

Connect a Battery Backup to the Control Box (Optional)......................................................................................................................17

PROGRAMMING ..................................................................................................................................................... 18-20

LCD Screen Menu................................................................................................................................................................................18

Programming Overview .................................................................................................................................................................. 18-19

Initial Setup...........................................................................................................................................................................................20

BASIC SETTINGS.................................................................................................................................................... 21-26

Limit and Force Learning......................................................................................................................................................................21

Remote Control Behaviour ...................................................................................................................................................................21

IR Behaviour.........................................................................................................................................................................................21

Input Command ...................................................................................................................................................................................22

Pedestrian Command...........................................................................................................................................................................22

Delay Motor 2 in Open and Close Direction.................................................................................................................................... 22-23

Timer To Close (TTC)............................................................................................................................................................................23

Reversal Time.......................................................................................................................................................................................24

E-Lock & Ram Blow Motor 1 for E-Lock ........................................................................................................................................ 24-25

Flashing Light - Pre-Flashing ................................................................................................................................................................25

Special Contact....................................................................................................................................................................................26

Soft & Hard Stop in Open and Close Direction.....................................................................................................................................26

Maintenance Counter ...........................................................................................................................................................................26

ADVANCED SETTINGS .......................................................................................................................................... 27-30

Password .............................................................................................................................................................................................27

Force Motors 1 & 2 Open and Close (Password Protected) .................................................................................................................28

Speed Motors 1 & 2 in Open and Close Direction (Password Protected) .............................................................................................29

Soft-Stop Speed in Open and Close Direction (Password Protected)...................................................................................................29

FACTORY RESET .........................................................................................................................................................30

WIRELESS PROGRAMMING ................................................................................................................................. 31-33

Remote Control Programming..............................................................................................................................................................31

MyQ Set-up.................................................................................................................................................................................... 32-34

OPERATION AND MAINTENANCE ....................................................................................................................... 35-37

Error Codes.................................................................................................................................................................................... 35-36

Accessories and Gate Hardware ..........................................................................................................................................................37

PROGRAMMING FLOW CHART............................................................................................................................ 38-42

CHAMBERLAIN LIMITED WARRANTY ................................................................................................................. 43-44