299.5 Battery backup unit .......................................................................................................................................................................

299.6 Cover piece kit ................................................................................................................................................................................

299.7 Closing time board kit .................................................................................................................................................................

309.8 Fire kit ...............................................................................................................................................................................................

309.9 Labels .................................................................................................................................................................................................

3110 Pre-installation ........................................................................................................................................................................

3110.1 General tips/Safety concerns .....................................................................................................................................................

3110.2 Operator/Door handing ...............................................................................................................................................................

3210.3 Installation examples ....................................................................................................................................................................

3210.4 Fastening requirements (but not included) .........................................................................................................................

3310.5 Tools required .................................................................................................................................................................................

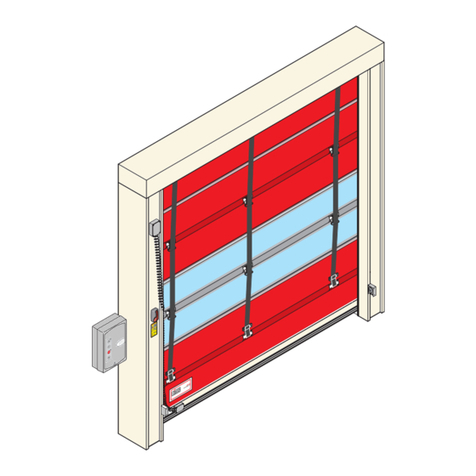

3411 Mechanical installation ........................................................................................................................................................

3711.1 PUSH arm system ...........................................................................................................................................................................

4311.2 PULL arm system ............................................................................................................................................................................

4911.3 Operator with sliding PUSH arm system ................................................................................................................................

5011.4 Inverse installation with PUSH arm system ..........................................................................................................................

5111.5 Inverse installation with PULL arm system ...........................................................................................................................

5211.6 Installation of coordination unit on Fire Door installations ............................................................................................

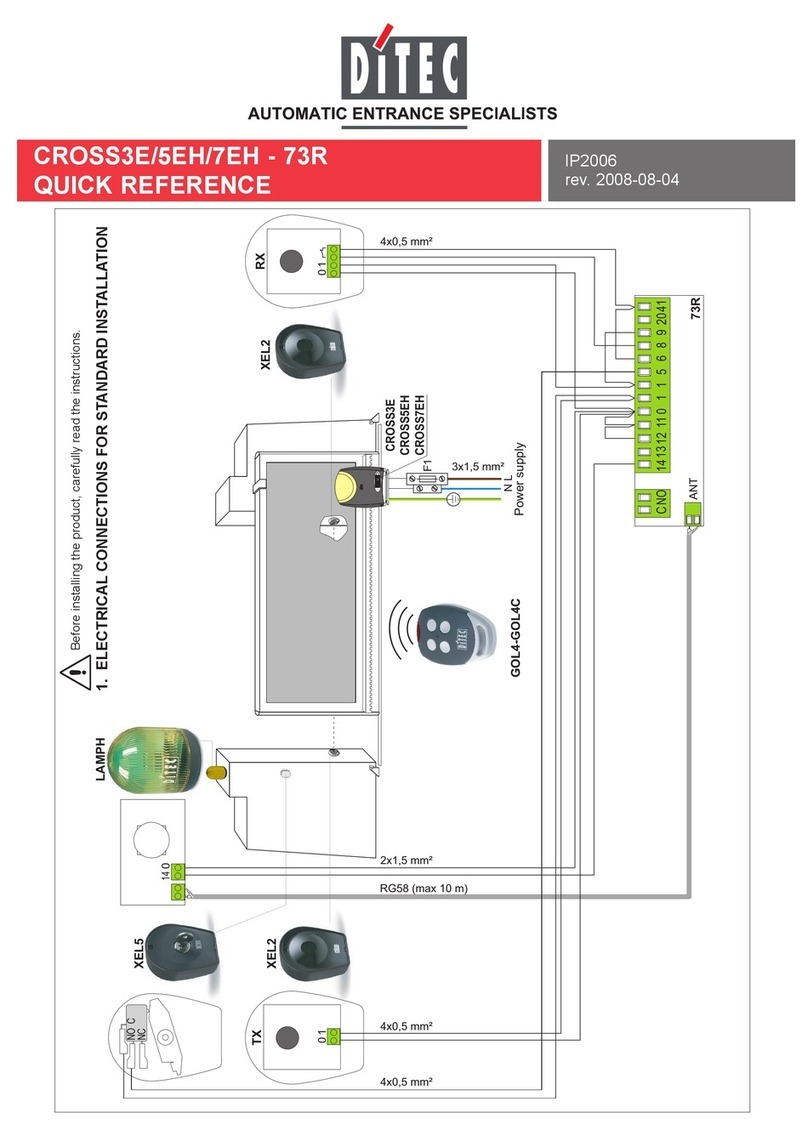

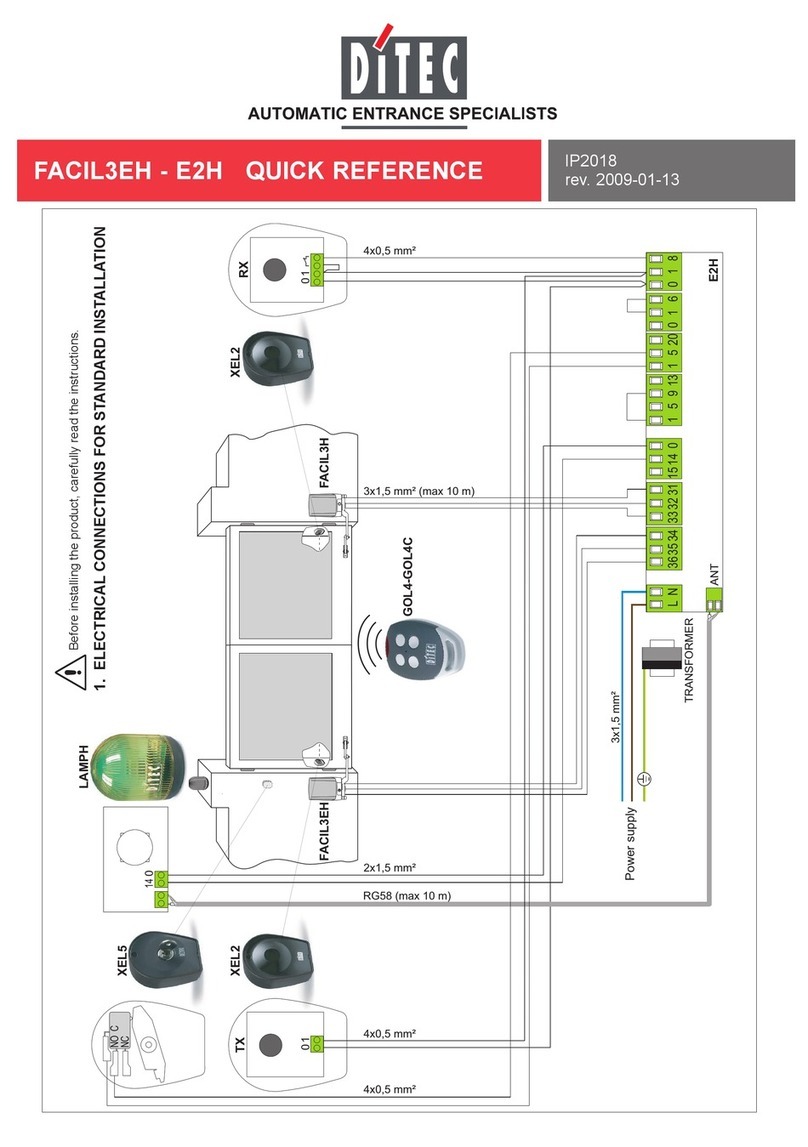

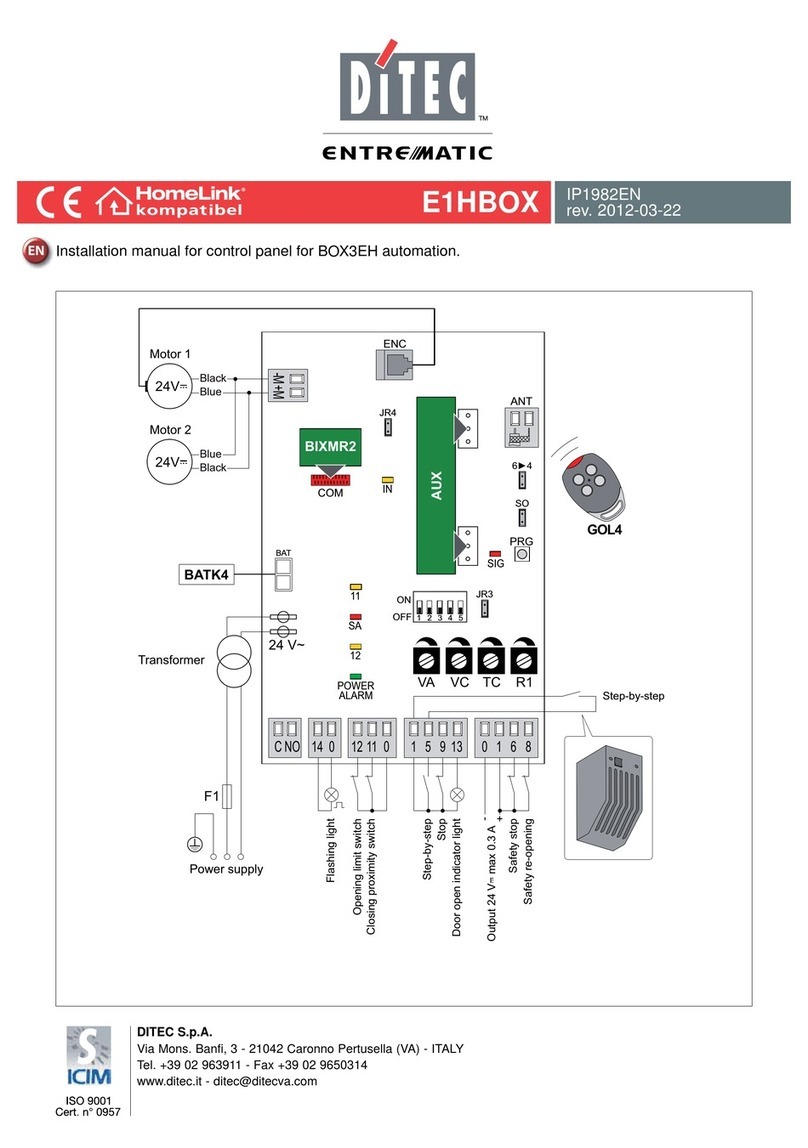

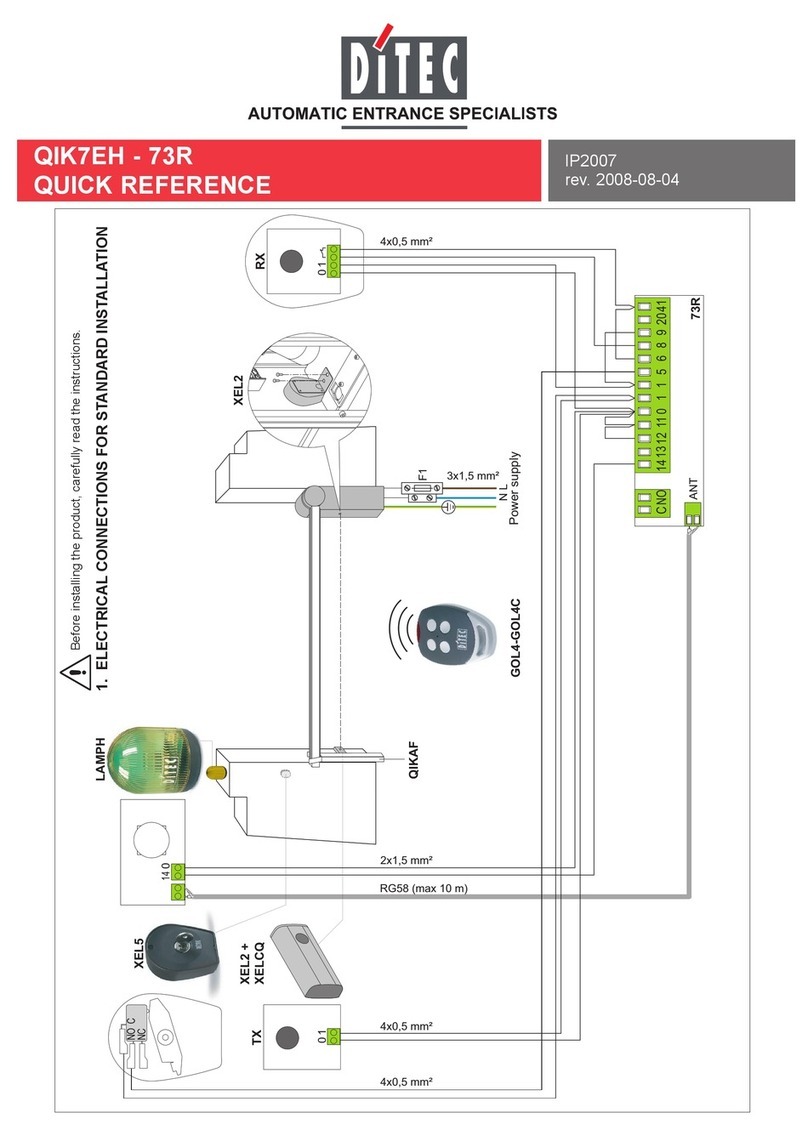

5812 Electrical connection .............................................................................................................................................................

5912.1 Control units ....................................................................................................................................................................................

5912.1.1 CUS7 (DAB305CU) .......................................................................................................................................................

5912.1.2 Arm system selection ..................................................................................................................................................

6012.1.3 Extension units DAB905ESE / DAB905ESA ............................................................................................................

6112.1.4 Extension unit DAB905ESE ........................................................................................................................................

6212.1.5 Extension unit DAB905ESA ........................................................................................................................................

6312.1.6 Installation on double doors ....................................................................................................................................

6312.2 How to cut the jumper on the sync cable for double doors ...........................................................................................

6412.3 Double door installations ...........................................................................................................................................................

6412.4 Settings for double doors ............................................................................................................................................................

6512.5 Sensor cable inlet ...........................................................................................................................................................................

6612.6 Reset and indication device for Fire Doors ............................................................................................................................

6813 Start-up ......................................................................................................................................................................................

6813.1 Spring pre-tension .........................................................................................................................................................................

6913.2 Micro switch ...................................................................................................................................................................................

6913.3 Adjusting the door stop ...............................................................................................................................................................

7113.4 Auto-learn-automatically sets back and latch check (recommended) .......................................................................

7213.4.1 Push the LEARN BUTTON (LRN) ...............................................................................................................................

7213.4.2 Double doors .................................................................................................................................................................

7213.5 General adjustment ......................................................................................................................................................................

7313.6 Connection of activation units and accessories ..................................................................................................................

7414 Cover ..........................................................................................................................................................................................

7414.1 Fitting and removing the cover .................................................................................................................................................

7414.2 Cover piece kit ................................................................................................................................................................................

7515 Signage .......................................................................................................................................................................................

7616 Advanced settings ..................................................................................................................................................................

7616.1 Learn with advanced setting of “back- and latch-check”..................................................................................................

7616.2 Revert to default values for “back- and latch-check" (Level 1) .......................................................................................

7716.3 Changing group of parameters (Level 2) ...............................................................................................................................

8016.4 Classification (Level 3) .................................................................................................................................................................

8116.5 Overhead Presence Detection and Interlock (Level 4) .....................................................................................................

8216.6 Enhanced Lock Kick, Fire Input and Extended Arm Selection (Level 5) .......................................................................

8317 Guide for installation and adjustments ..........................................................................................................................

8317.1 Complementary Safety Devices Swing Doors ......................................................................................................................

8317.2 Swing Doors Opening and Closing Time ................................................................................................................................

8317.2.1 How to find the correct opening and closing time ...........................................................................................

8417.3 Diagrams for Door weight ..........................................................................................................................................................

8417.3.1 Aluminium frame with glass .....................................................................................................................................

1020527-DIen-3.0Issue 2021-06-074