Architectural Series®

Installation & Use

INSTALLATION 4

CLEANCES & PREPATION

Full Chimney Installation

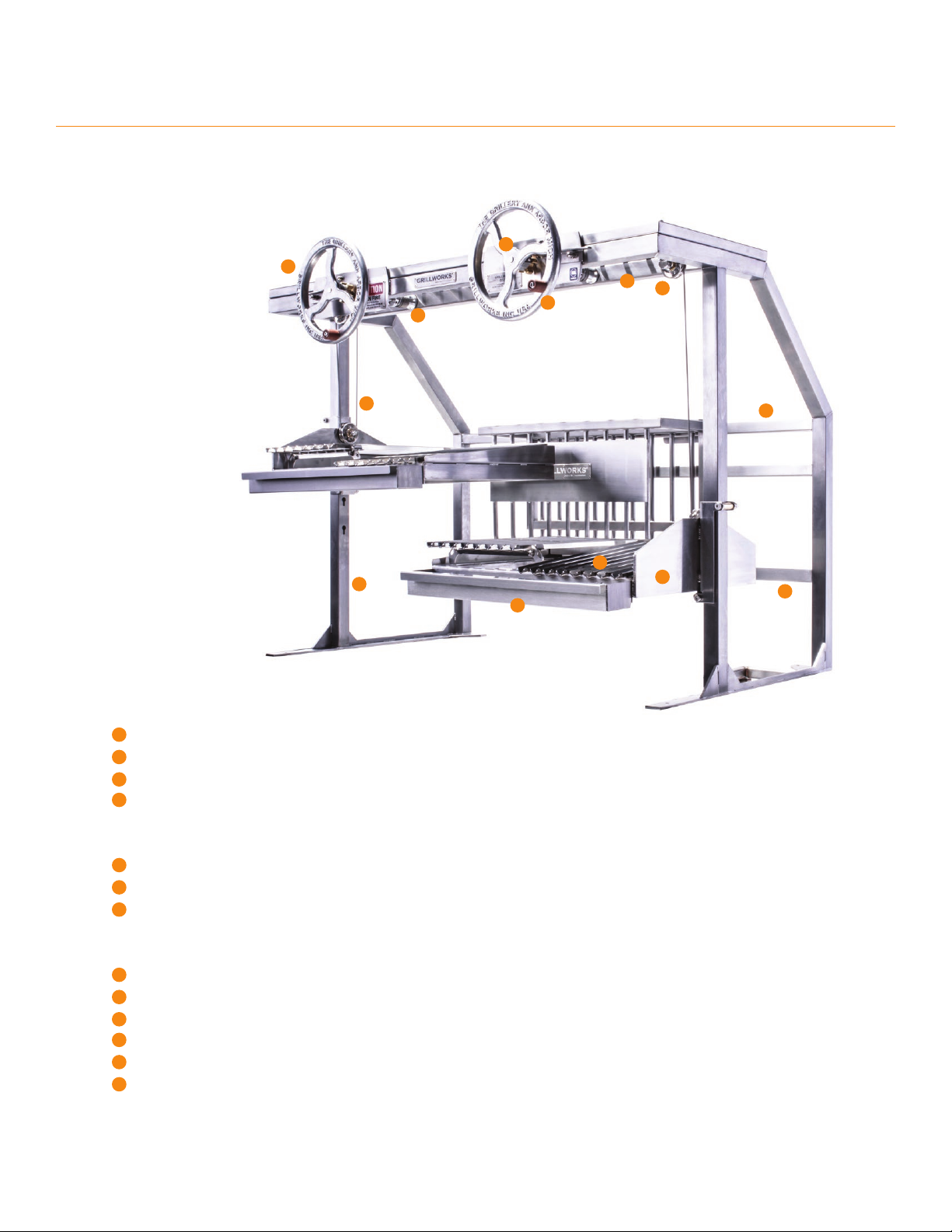

e Architectural grill’s uprights also serve as its travel

track, so should be installed with 2” clearance to the

enclosure walls on models with rollers (Dual-crankwheel

Architecturals) or a minimum of .5” for non-roller grills

(Single- crankwheel Architecturals). e rear of the grill

li frame and cooking surface should have at least 1”

of clearance to the rear wall of the enclosure, or in cases

where the optional Fire Cage is present, 1” minimum

to the cage (to allow easy grill surface travel—not a

safety issue).

ALWAYS USE A PROFESSIONAL FOR

CONSTRUCTION OF THE MASONRY

ENCLOSURE. MASONRY FAILURE COULD

CAUSE COSTLY DAMAGE, FIRE OR DEATH.

Only install the Architectural on a non-combustible base.

A strong substrate such as concrete lined with industry-

standard refractory rebrick is considered ideal. e

base should be 30-36” above the oor for comfortable

cooking operation. Walls should be constructed of

similar noncombustible material, and of a thickness great

enough to prevent excessive transmission of heat to the

outside (the exact amount will vary both with ventilation

and construction). Chefs oen want workspace at the

grill, so if dimensions allow you may set the grill up to

6-8” back from the front lip of the enclosure to provide a

staging area.

Open Installations

is approach leaves the top of the grill exposed. is is

usually done with side-crankwheel grills. ere are two

common types:

Cut Out: e grill stands in a three-sided cutout with

the front OPEN (no wall). e cutout recess should be

10” deep for the best balance of heat containment and

aesthetics. e same clearances to the walls and rear

apply as to the full chimney installation type. e recess

contains the re/cooking heat so is a good choice for

outdoor or residential projects.

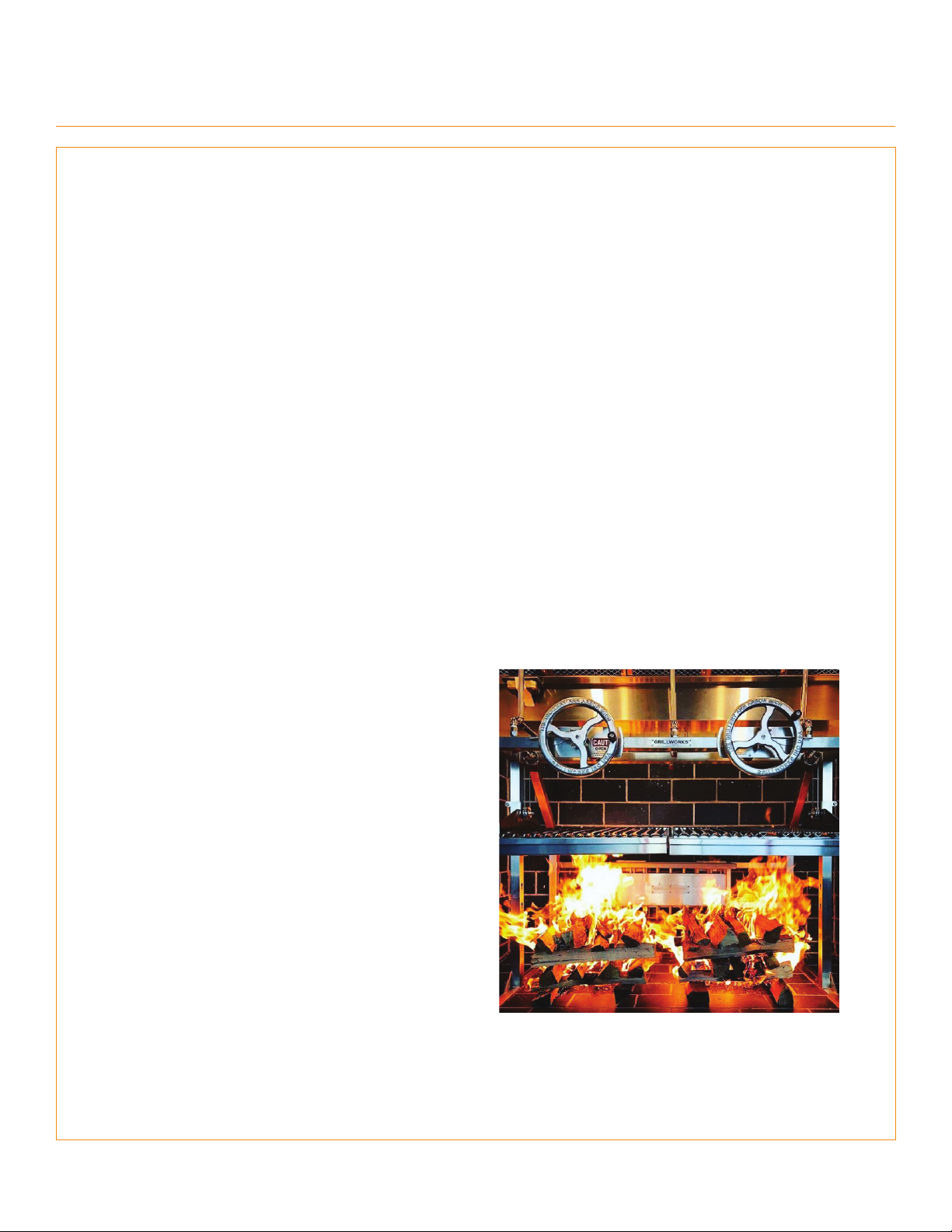

Open Hearth: e grill is mounted on a larger at

hearth, without any recess below the grill. is type of

installation is common in restaurant applications as the

ventilation is controlled (no wind) and it allows the chefs

to use the whole hearth for staging, direct coal searing

or other improvised cooking. e re is commonly

moved around to control what area of the grill is hoest,

and most grilling will likely be performed with the

surface very close to the coals as heat dissipates rapidly

without containing walls.

THIS GRILL MUST BE INSTALLED BY A

QUALIFIED PROFESSIONAL. THE ENTIRE AREA

OVER THE GRILL MUST BE NONCOMBUSTIBLE

EXTENDING 48” IN ALL DIRECTIONS. ANY

FAÇADE OR CLADDING MATERIALS MUST ALSO

BE NON-COMBUSTIBLE. IN A PROFESSIONAL

SEING THE GRILL MUST BE INSTALLED

UNDER AN APPROVED TYPE 1 NFPA 96 OR NFPA

96 EQUIVALENT SOLID FUEL HOOD SYSTEM.