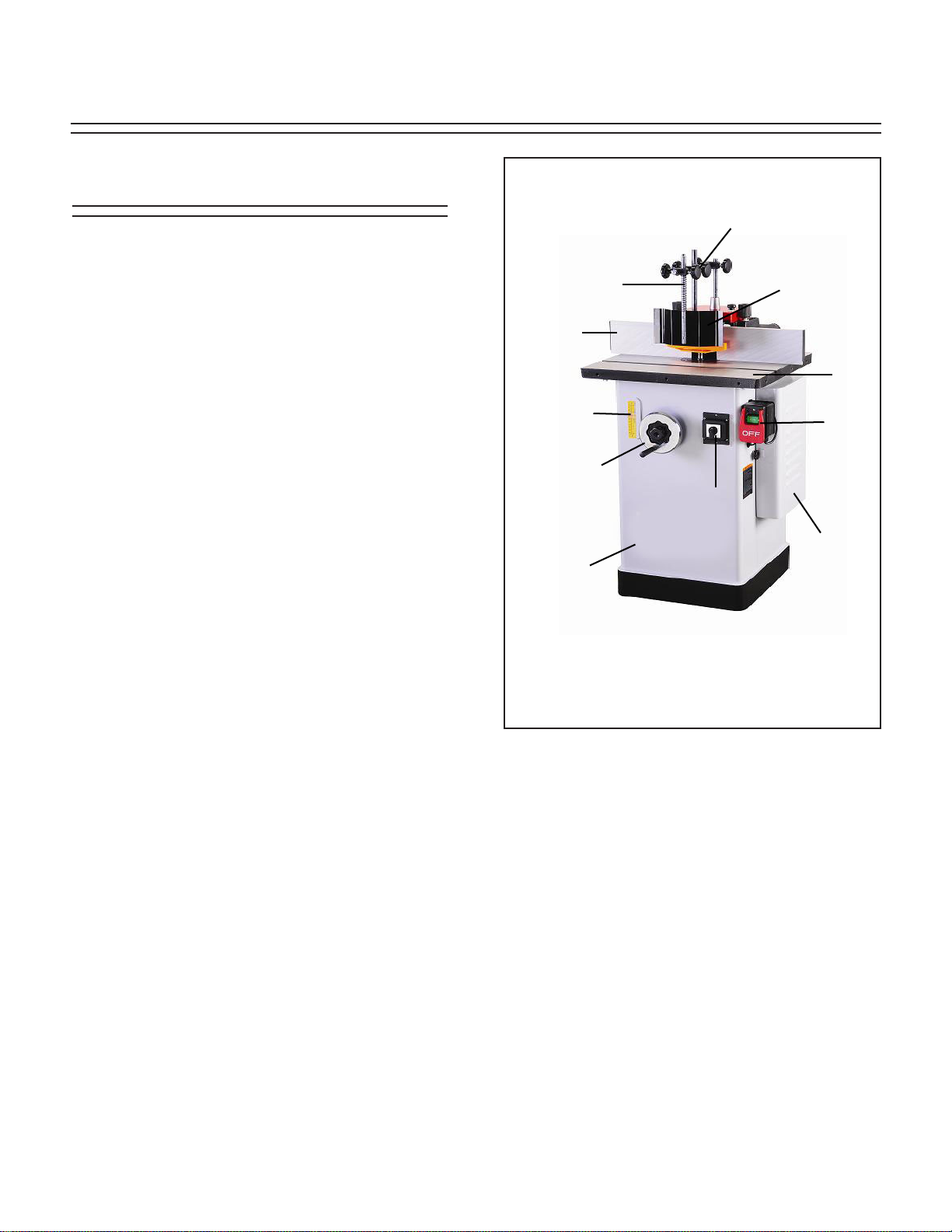

ated with this Spindle Moulder. Accidents are No list of safety guidelines can be complete.

Every shop environment is different. Always

consider safety first, as it applies to your

individual working conditions. Use this and

other machinery with caution and respect.

Failure to do so could result in serious per-

sonal injury, damage to equipment, or poor

work results.

Like all machines there is danger associ-

frequently caused by lack of familiarity or

failure to pay attention. Use this machine

with respect and caution to lessen the pos-

sibility of operator injury. If normal safety

precautions are overlooked or ignored, seri-

ous personal injury may occur.

Additional Safety Instructions for Shapers

1. HAND POSITIONING. Never place hands

directly over or in front of the cutter. As one

hand approaches the cutter, move it in an

arc motion away from the cutter to the out-

feed side. Always keep hand at least 6" away

from the cutter while operating.

2. SAFETY DEVICES. Use a fixture, jig, or

hold-down device to decrease the chances

of injury.

3. SAFETY GUARDS. DO NOT remove the

retractable guard on the fence. Use a guard

or other type of protective device at all times.

Use overhead guard when the fence is

removed.

4. CUTTER HEIGHT. Keep any unused portion

of the cutter below the table surface.

5. STOCK LENGTH. Do not use stock shorter

than 6 inches without special fixtures or jigs.

Where practical, shape longer stock and cut

to size.

6. STOCK CONDITION. The danger of kick-

back is increased when the stock has knots,

holes, or foreign objects in it. Warped stock

should be run through a jointer before you

run it through a shaper.

7. BLIND CUT WHEN POSSIBLE. Blind cuts

keep the cutters on the underside of the

workpiece and provide a distance guard for

the operator.

8. TEST ROTATION. With the machine

unplugged, rotate the spindle to test any

new setup to ensure proper cutter clearance

before starting the machine.

9. DEPTH OF CUT. Never remove too much

material in one pass. Several light passes

are safer and produce a cleaner finish.

10. SHAPING CONTOURED WORK. Always

use a rub collar and a template. DO NOT

start out at a corner. See the rub collar sec-

tion further on in the manual.

11. FEEDING THE WORKPIECE. Always feed

the workpiece against the rotation of the cut-

ter. Never force materials through the shaper.

Let the cutters do the work. Excessive force

is likely to result in poor cutting results and

will cause dangerous kickback conditions.

12. SECURING NUTS AND KNOBS. Never

operate the shaper without the second lock-

ing nut in place over the spindle nut. Always

ensure that the cutters, fence, and spindle

elevator knob have been tightened properly

before beginning any operation.

5