INTRODUCTION

Foreword

www.

grizzly.com

Contact Info

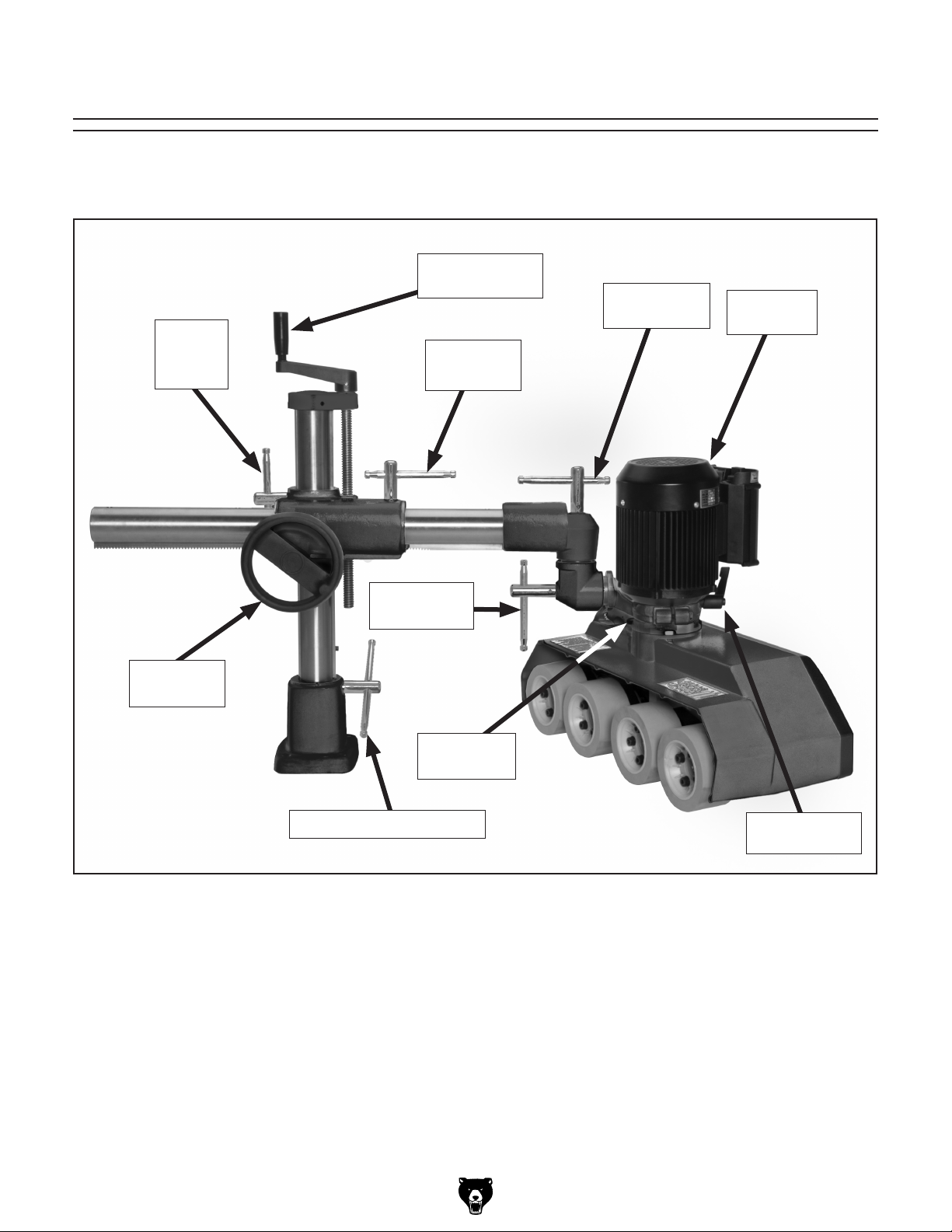

Functional Overview