7. ONLY ALLOW TRAINED AND PROP-

ERLY SUPERVISED PERSONNEL TO

OPERATE MACHINERY. Make sure

operation instructions are safe and clearly

understood.

8. KEEP CHILDREN/VISITORS AWAY.

Keep all children and visitors away from

machinery. When machine is not in use,

disconnect it from power, lock it out, or

disable the switch to make it difficult for

unauthorized people to start the machine.

9. UNATTENDED OPERATION. Leaving

machine unattended while its running

greatly increases the risk of an accident or

property damage. Turn machine Off and

allow all moving parts to come to a com-

plete stop before walking away.

10. DO NOT USE IN DANGEROUS

ENVIRONMENTS. DO NOT use machin-

ery in damp, wet locations, or where any

flammable or noxious fumes may exist.

11. KEEP WORK AREA CLEAN AND WELL

LIGHTED. Clutter and dark shadows may

cause accidents.

12. USE A GROUNDED POWER SUPPLY

RATED FOR THE MACHINE AMPERAGE.

Grounded cords minimize shock hazards.

Operating machine on an incorrect size of

circuit increases risk of fire.

13.

ALWAYS DISCONNECT FROM POWER

SOURCE BEFORE SERVICING

MACHINERY. Make sure switch is in

OFF

position before reconnecting.

14. MAINTAIN MACHINERY WITH CARE.

Keep blades sharp and clean for best and

safest performance. Follow instructions for

lubricating and changing accessories.

15. MAKE SURE GUARDS ARE IN PLACE

AND WORK CORRECTLY BEFORE

USING MACHINERY.

Safety Instructions for Machinery

16. REMOVE CHUCK KEYS OR ADJUSTING

TOOLS. Make a habit of never leaving

chuck keys or other adjustment tools in/on

the machine—especially near spindles!

17. DAMAGED MACHINERY. Check for bind-

ing or misaligned parts, broken parts,

loose bolts, other conditions that may

impair machine operation. Always repair or

replace damaged parts before operation.

18. DO NOT FORCE MACHINERY. Work at

the speed for which the machine or acces-

sory was designed.

19. SECURE WORKPIECE. Use clamps or

a vise to hold the workpiece when practi-

cal. A secured workpiece protects your

hands and frees both hands to operate the

machine.

20. DO NOT OVERREACH. Maintain stability

and balance at all times when operating

machine.

21. MANY MACHINES CAN EJECT

WORKPIECES TOWARD OPERATOR.

Know and avoid conditions that cause the

workpiece to "kickback."

22. STABLE MACHINE. Machines that move

during operations greatly increase the

risk of injury and loss of control. Verify

machines are stable/secure and mobile

bases (if used) are locked before starting.

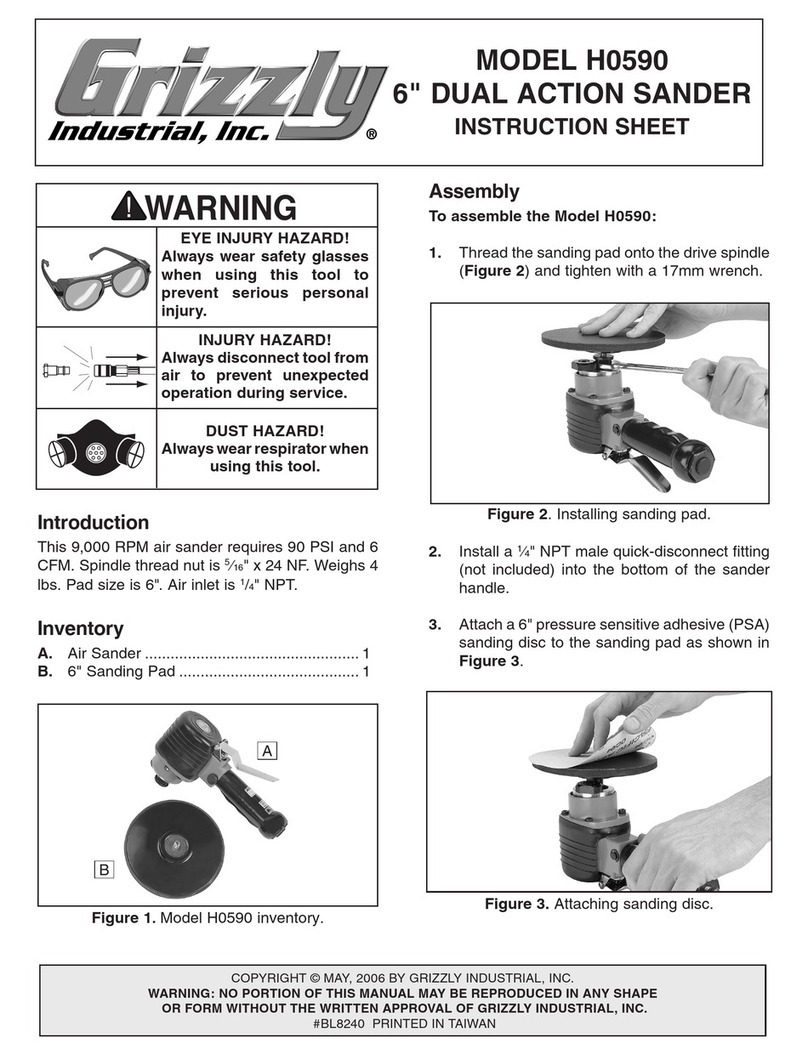

23. CERTAIN DUST MAY BE HAzARDOUS

to the respiratory systems of people and

animals, especially fine dust. Be aware of

the type of dust you are exposed to and

always wear a respirator designed to filter

that type of dust.

24. EXPERIENCING DIFFICULTIES. If at

any time you are experiencing difficulties

performing the intended operation, stop

using the machine! Contact our Technical

Support Department at (570) 546-9663.