- 3 -

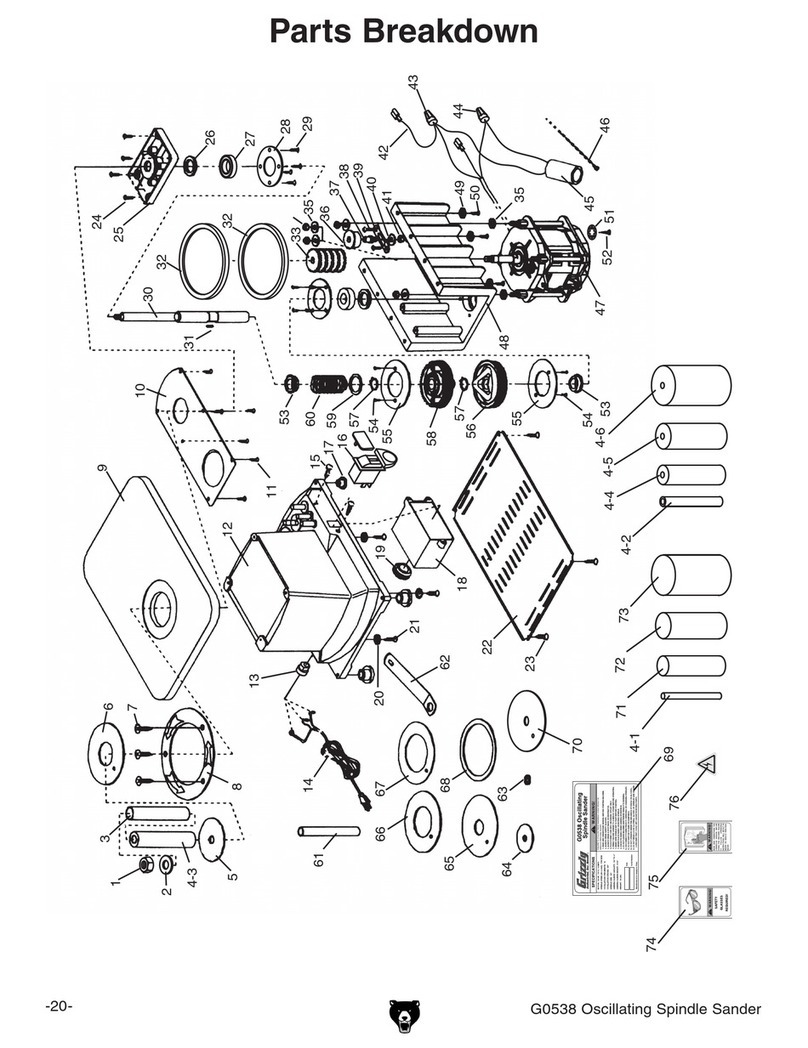

G1071 Oscillating Spindle Sander

II. SAFETY RULES FOR ALL TOOLS

The Model G1071 is inherently dangerous. Using the tool with respect and caution will

lessen the possibility of mechanical damage or operator injury. If normal safety precau-

tions are overlooked or ignored, serious personal injury may occur.

This machine is specifically designed for wood sanding operations. Modifications or

improper use of this tool can result in damage to the machine and possible operator injury,

and will void all warranties. If you are confused about any aspect of this machine, DO NOT

use it until you have resolved any questions you might have. The following are important

safety rules for all tools:

1. KNOW YOUR POWER TOOL. Read

the owner’s manual carefully. Learn the

tool’s applications and limitations, as

well as its hazards.

2. KEEP ALL GUARDS IN PLACE and in

working order.

3. GROUND ALL TOOLS. If an adapter is

used to accommodate a two-prong

receptacle, the adapter plug must be

attached to a known ground. Never

remove the grounding prong.

4. REMOVE ADJUSTING KEYS AND

WRENCHES. Make it a habit to check

that keys and adjusting wrenches are

removed from the machine before turn-

ing it on.

5. KEEP WORK AREA CLEAN.

Cluttered areas and benches invite

accidents.

6. AVOID DANGEROUS ENVIRON-

MENTS. Do not use power tools in

damp or wet locations or expose them

to rain. Keep your work area well light-

ed.

7. KEEP CHILDREN AND VISITORS

AWAY. All children and visitors should

be kept a safe distance away from your

work area. Serious injuries could occur.

8. MAKE WORKSHOP CHILD-PROOF

with padlocks, master switches, or by

removing starter keys.

9. DO NOT FORCE TOOL. Tools work

better and more safely when they are

allowed to work at their own speed.

10. USE THE RIGHT TOOL. Do not use a

tool or an attachment to do a job that it

was not intended to perform.

11. WEAR PROPER APPAREL. Do not

wear loose clothing, gloves, neckties, or

jewelry that might get caught in moving

parts. Non-slip footwear is also recom-

mended. Wear a hat or other protective

head wear if your hair is long.

12. USE SAFETY GLASSES AND EAR

PROTECTION. Also use a dust mask if

the sanding operation is dusty.

13. SECURE YOUR WORK. Use clamps or

a fixture to hold your work. It is safer

than using your hands and frees up

both hands for operating the tool.

14. DO NOT OVERREACH. Keep proper

footing and balance at all times.

15. MAINTAIN TOOLS IN TOP CONDI-

TION. Keep tools sharp and clean for

best and safest performance. Follow

instructions for lubricating and changing

accessories.