Table Of Contents PAGE

1. SAFETY

SAFETY RULES FOR POWER TOOLS ..........................................................................................2-3

SAFETY RULES FOR THE WIDE BELT SANDER ............................................................................4

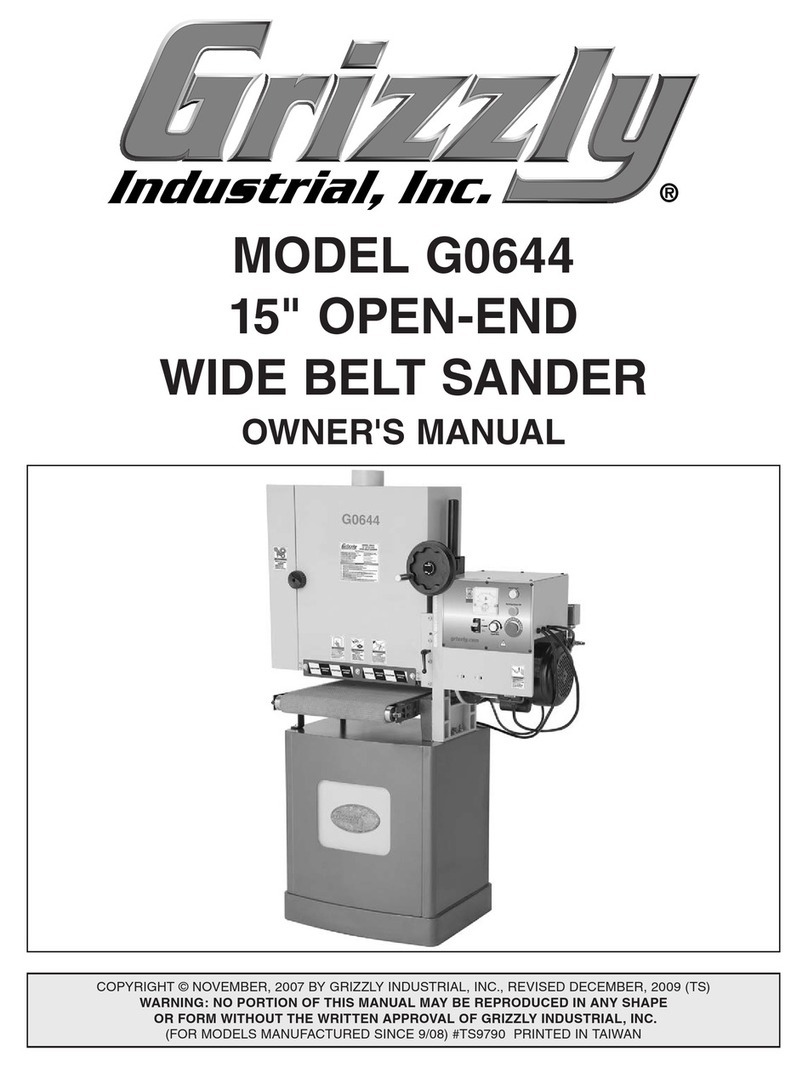

2. INTRODUCTION ........................................................................................................................................5

3. CIRCUIT REQUIREMENTS ......................................................................................................................6

220V SINGLE-PHASE..........................................................................................................................6

GROUNDING ......................................................................................................................................7

EXTENSION CORDS ..........................................................................................................................7

WIRING ................................................................................................................................................7

4. MACHINE FEATURES................................................................................................................................8

EXTERNAL FEATURES ......................................................................................................................8

CONTROL PANEL ..............................................................................................................................8

ACCESS DOORS ................................................................................................................................9

5. SET UP......................................................................................................................................................10

UNPACKING ......................................................................................................................................10

PIECE INVENTORY ..........................................................................................................................10

HARDWARE RECOGNITION CHART ..............................................................................................11

CLEAN UP..........................................................................................................................................12

SITE CONSIDERATIONS ..................................................................................................................12

BEGINNING ASSEMBLY ..................................................................................................................13

HANDWHEEL HANDLE ....................................................................................................................13

PLATEN..............................................................................................................................................14

AIR HOSE ..........................................................................................................................................15

SANDING BELT ................................................................................................................................15

SANDING BELT TENSION ................................................................................................................16

PRESSURE ROLLERS ......................................................................................................................16

DUST COLLECTION..........................................................................................................................17

TEST RUN ....................................................................................................................................17-18

RECOMMENDED ADJUSTMENTS ..................................................................................................18

6. OPERATIONS ..........................................................................................................................................19

BEFORE STARTING..........................................................................................................................19

CHOOSING SANDPAPER ................................................................................................................19

CONVEYOR HEIGHT ........................................................................................................................20

FEED BELT SPEED ..........................................................................................................................20

LOAD METER ....................................................................................................................................21

OPERATION ......................................................................................................................................21

PLATEN DEPTH ................................................................................................................................22

CLEANING PADS ..............................................................................................................................22

7. MAINTENANCE ........................................................................................................................................23

GENERAL ..........................................................................................................................................23

LUBRICATION ..................................................................................................................................23

CLEANING SANDING BELTS ..........................................................................................................23

EMPTYING FILTERS ........................................................................................................................23

MAINTENANCE LOG ........................................................................................................................24

8. SERVICE ADJUSTMENTS ......................................................................................................................25

OSCILLATION TIMING ................................................................................................................25-26

OSCILLATION SPEED ......................................................................................................................26

OSCILLATION RETURN....................................................................................................................27

LIMIT SWITCHES ..............................................................................................................................27

PRESSURE ROLLER DEPTH ..........................................................................................................28

PRESSURE ROLLER TENSION ......................................................................................................29

FEED BELT TENSION ......................................................................................................................30

FEED BELT TRACKING ....................................................................................................................30

V-BELT TENSION ..............................................................................................................................31

REPLACING V-BELTS..................................................................................................................31-32

PLATEN GRAPHITE ..........................................................................................................................33

AIR SYSTEM......................................................................................................................................33

REPLACING BRAKES ......................................................................................................................34

SERVICE LOG ..................................................................................................................................35

9. CLOSURE ................................................................................................................................................36

DATA SHEET ........................................................................................................................................................37

AIR SYSTEM..........................................................................................................................................................38

WIRING DIAGRAM ..........................................................................................................................................39-41

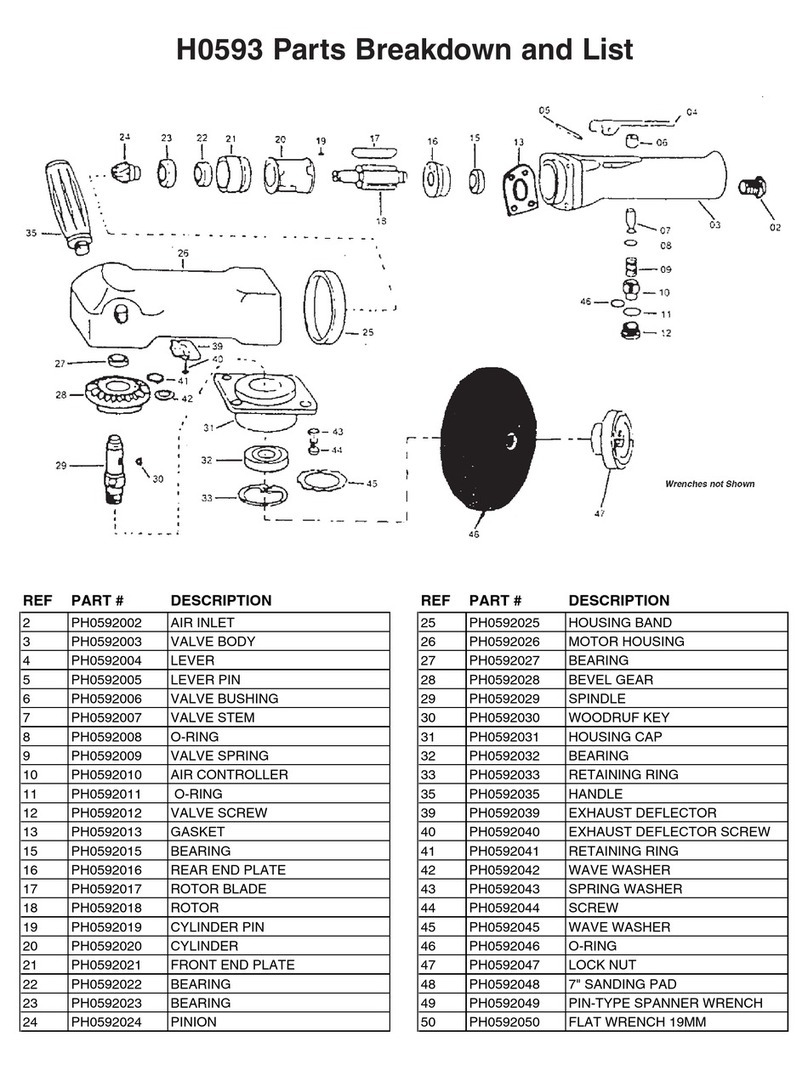

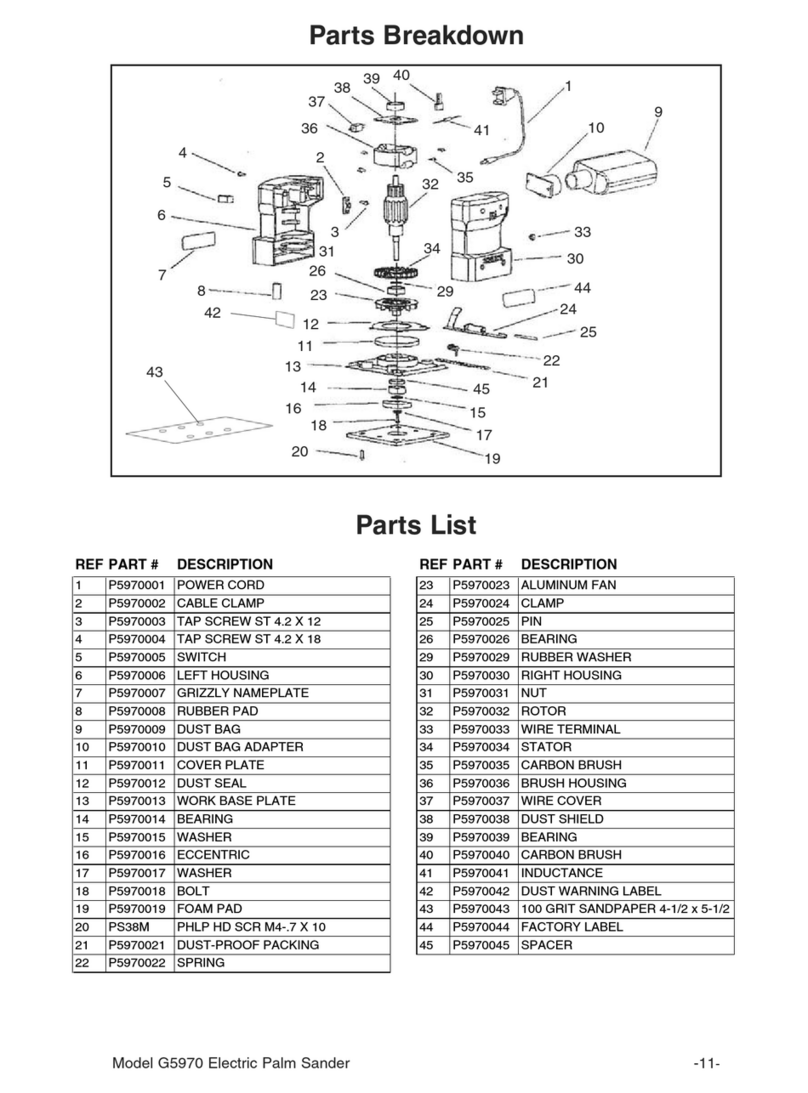

PARTS BREAKDOWN ....................................................................................................................................42-51

TROUBLESHOOTING......................................................................................................................................52-53

WARRANTY AND RETURNS................................................................................................................................54