Table of Contents

INTRODUCTION............................................... 2

SECTION 1: SAFETY..................................... 10

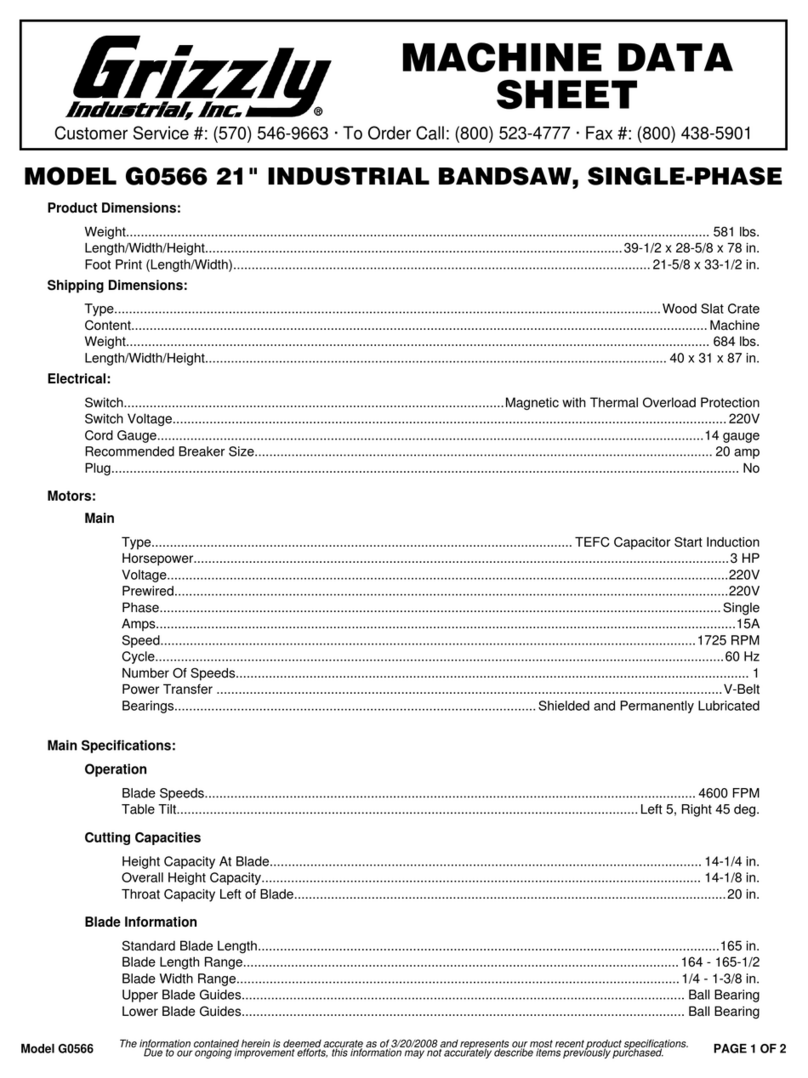

SECTION 2: POWER SUPPLY ...................... 15

SECTION 3: SETUP ....................................... 18

SECTION 4: OPERATIONS ........................... 37

SECTION 5: SHOP MADE SAFETY

ACCESSORIES .............................................. 54

SECTION 6: AFTERMARKET ACCESSORIES

FROM GRIZZLY ............................................. 61

SECTION 7: MAINTENANCE......................... 63

SECTION 8: SERVICE ................................... 65

SECTION 9: WIRING...................................... 73

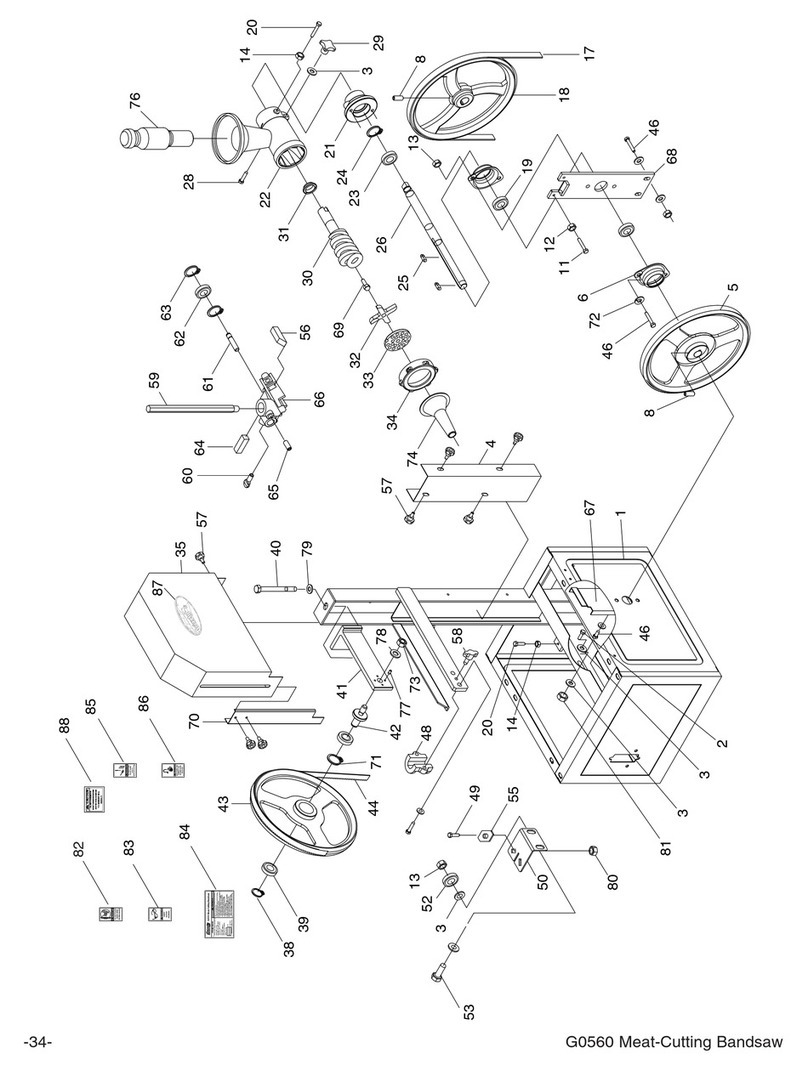

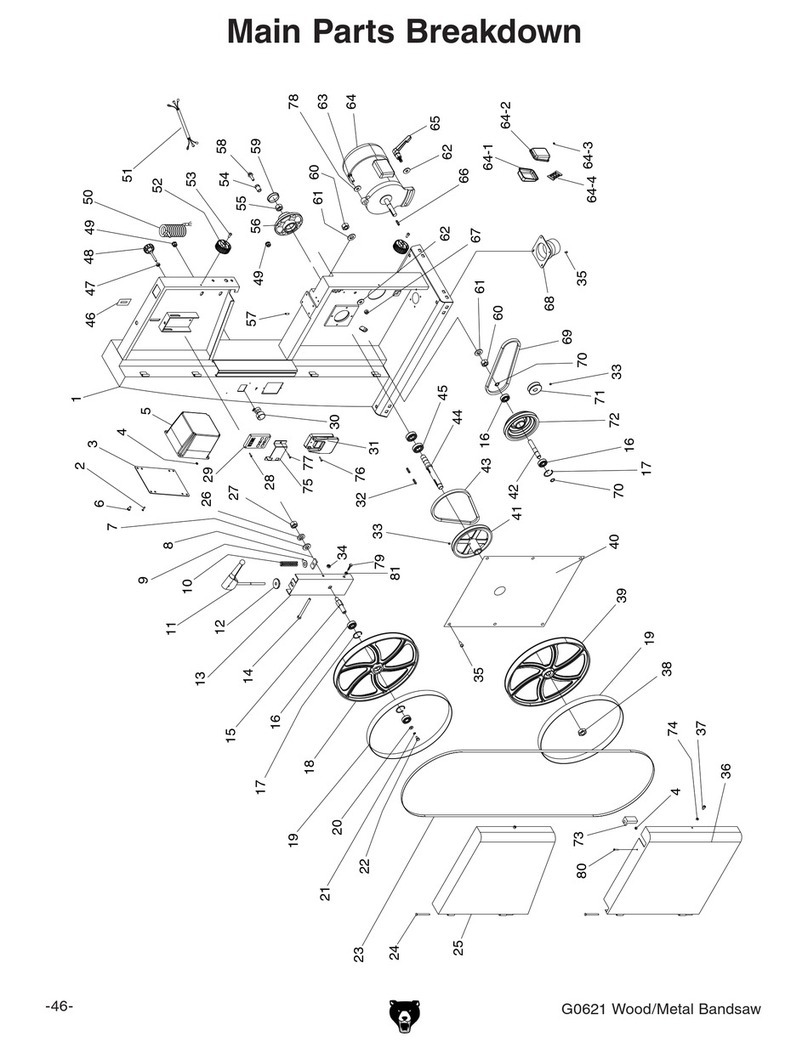

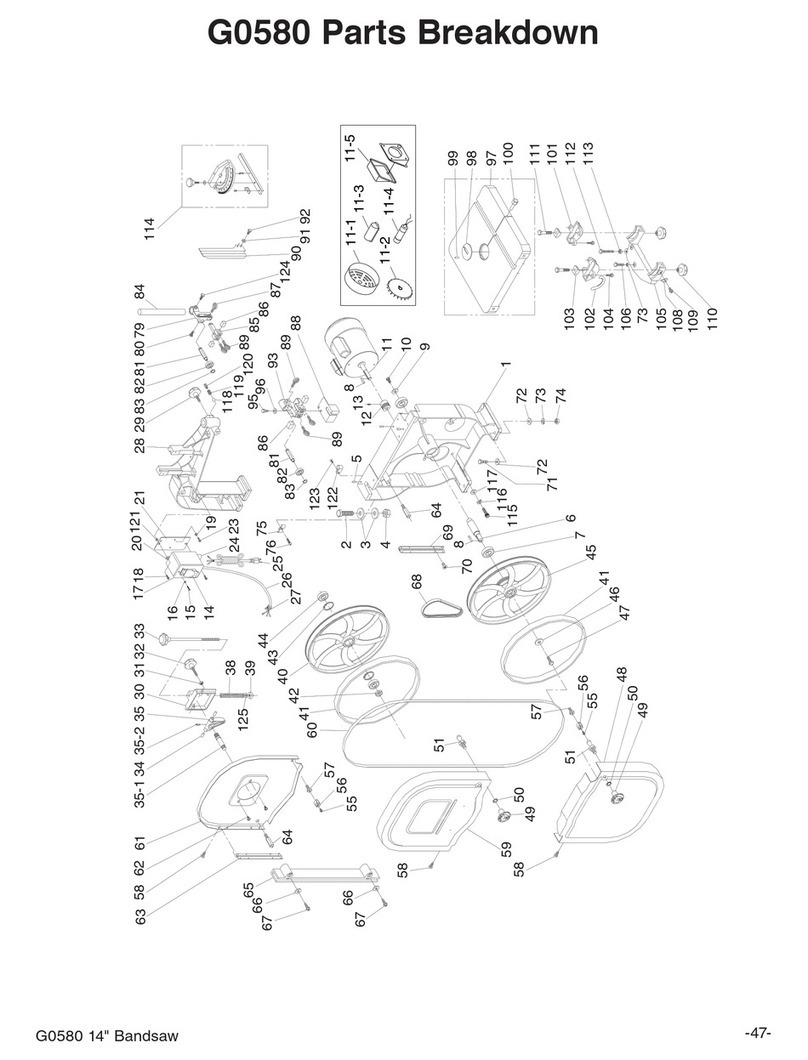

SECTION 10: PARTS..................................... 80

WARRANTY AND RETURNS ...................... 101