Table of Contents

INTRODUCTION............................................... 2

Machine Description ...................................... 2

Contact Info.................................................... 2

Manual Accuracy ........................................... 2

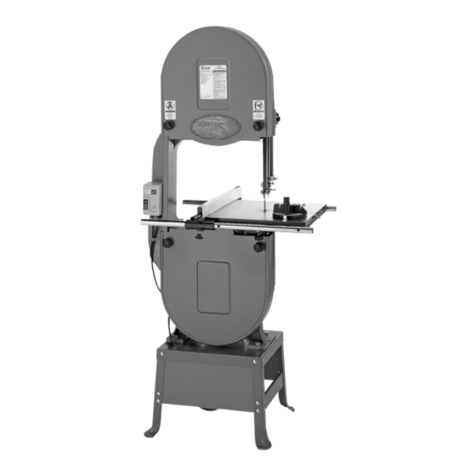

Identification ................................................... 3

Controls & Components ................................. 4

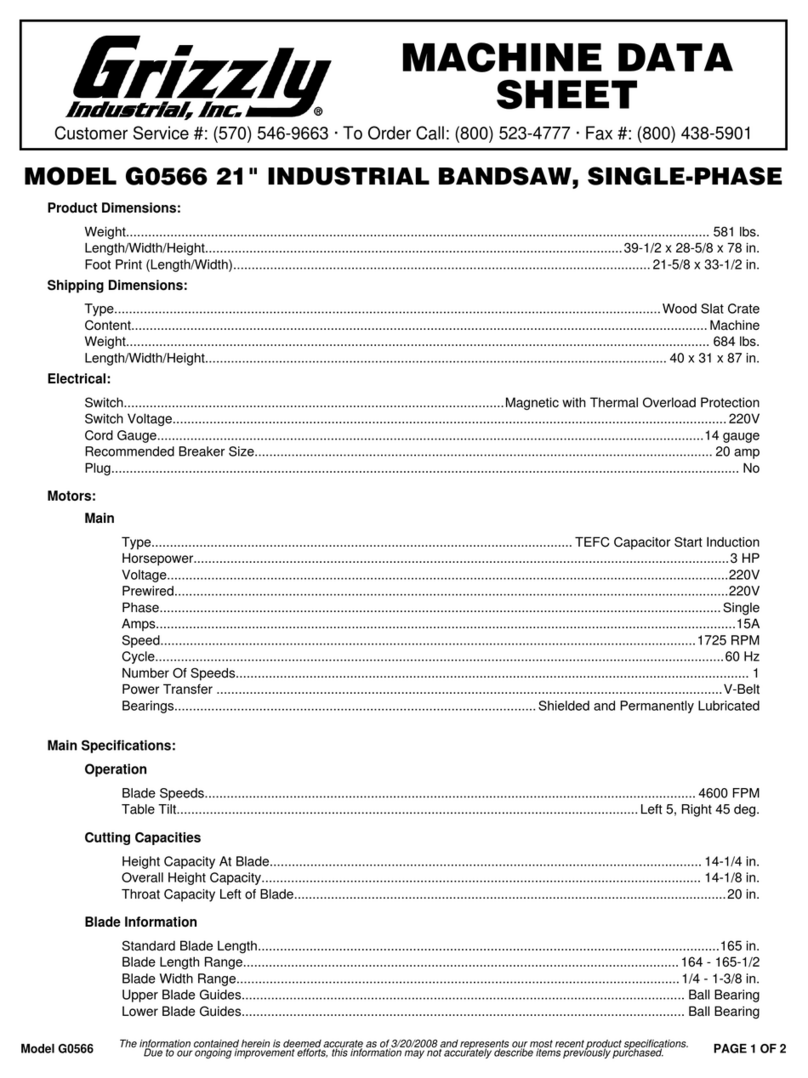

Machine Data Sheet ...................................... 6

SECTION 1: SAFETY....................................... 8

Safety Instructions for Machinery .................. 8

Additional Safety for Metal Bandsaws ......... 10

SECTION 2: POWER SUPPLY ...................... 11

SECTION 3: SETUP ....................................... 14

Needed for Setup ......................................... 14

Unpacking .................................................... 14

Inventory ...................................................... 15

Cleanup ........................................................ 16

Site Considerations ...................................... 17

Assembly ..................................................... 18

Test Run ...................................................... 21

Inspections & Adjustments .......................... 22

SECTION 4: OPERATIONS ........................... 23

Operation Overview ..................................... 23

Operation Tips ............................................. 24

Inspecting Workpieces ................................. 25

Selecting Blades .......................................... 25

Changing Blade ........................................... 27

Adjusting Blade Tension .............................. 28

Blade Care & Break-In ................................. 29

Blade Breakage ........................................... 29

Chip Inspection Chart .................................. 30

Adjusting Blade Guides ............................... 30

Adjusting Feed Rate .................................... 31

Using Vise .................................................... 32

Adjusting Work Stop .................................... 33

Changing Blade Speed ................................ 33

Blade Speed Chart ...................................... 35

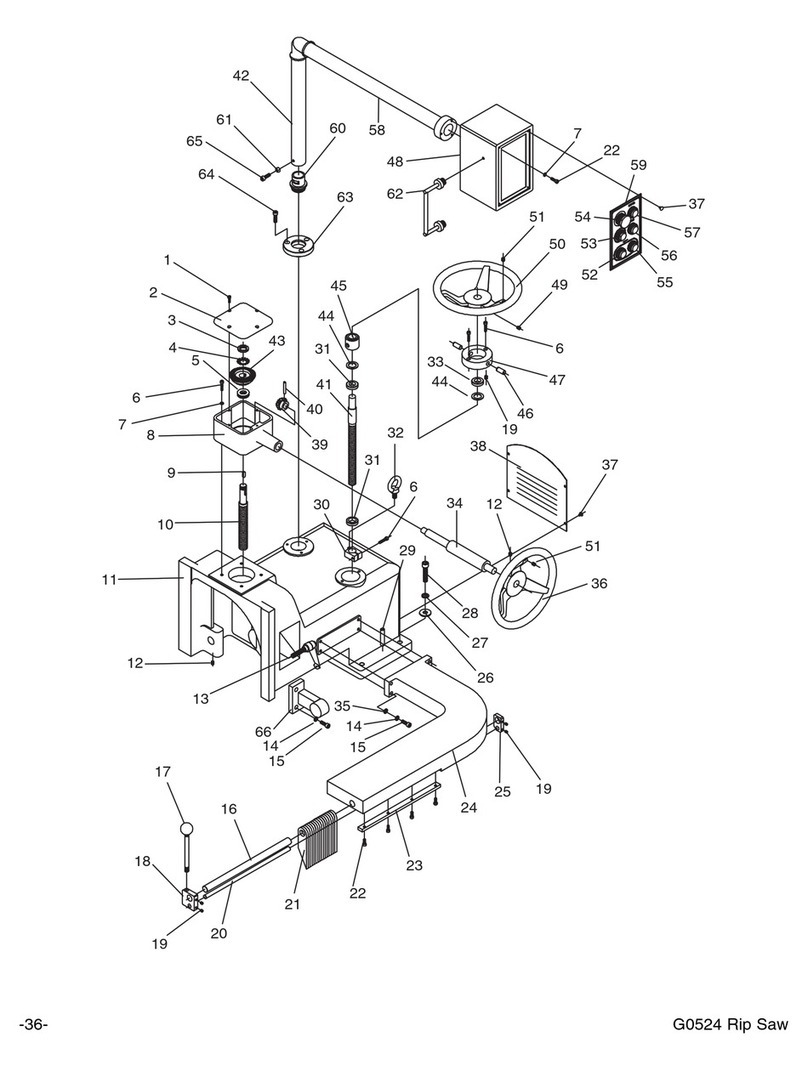

Vertical Operation ........................................ 36

Cutting Fluid ................................................. 37

Cutting Fluid System .................................... 38

SECTION 5: ACCESSORIES......................... 39

SECTION 6: MAINTENANCE......................... 40

Schedule ...................................................... 40

Cleaning ....................................................... 40

Lubrication ................................................... 40

SECTION 7: SERVICE ................................... 42

Troubleshooting ........................................... 42

Adjusting Blade Tracking ............................. 45

Squaring Blade to Bed Table ....................... 46

Adjusting Blade Guide Bearings .................. 46

Adjusting Downfeed Stop Bolt ..................... 47

SECTION 8: WIRING...................................... 48

Wiring Safety Instructions ............................ 48

Wiring Diagrams .......................................... 49

Electrical Components ................................. 50

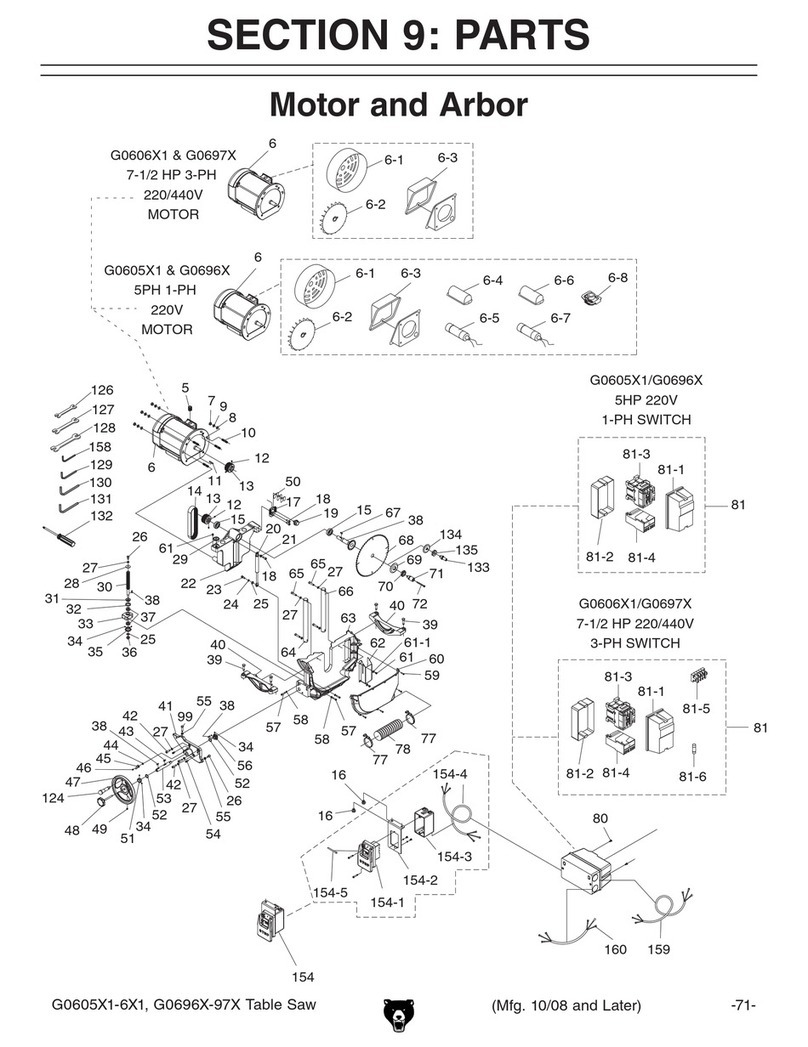

SECTION 9: PARTS....................................... 51

Cabinet & Base ............................................ 51

Bow & Motor ................................................ 53

Gearbox ....................................................... 55

Labels & Cosmetics ..................................... 56

WARRANTY & RETURNS ............................. 57