4

Note: Add shims between the undercarriage and

the tractor frame to reduce any gap if necessary.

Use shims until there is a gap of 1/16” or less on

the front. See attached diagram for the proper

location and orientation of each shim. Don’t put all

the shims on one side of the undercarriage.

Caution:

• Always use caution when working around any

equipment.

• Always wear safety glasses.

• Follow tractor manufacturer’s safety guidelines

when installing this product.

• Use paint where necessary to prevent rust.

• Do not modify or permit anyone else to modify

or alter the equipment and its components

without rst consulting Grouser Products.

Note:

• When installing hardware, only nger tighten

until all hardware is in place.

• A full diagram of the assembly with the full list

of parts is on pages 6-7.

• Tractor frame not shown in some diagrams for

clarity.

• Unstrap and remove any components that are

attached for shipping.

• Read all instructions prior to performing

installation.

Undercarriage Installation

1. Remove existing toolboxes, front weights, and tow

cable holder if equipped. Tow cable holder can be

reinstalled later with the undercarriage.

1

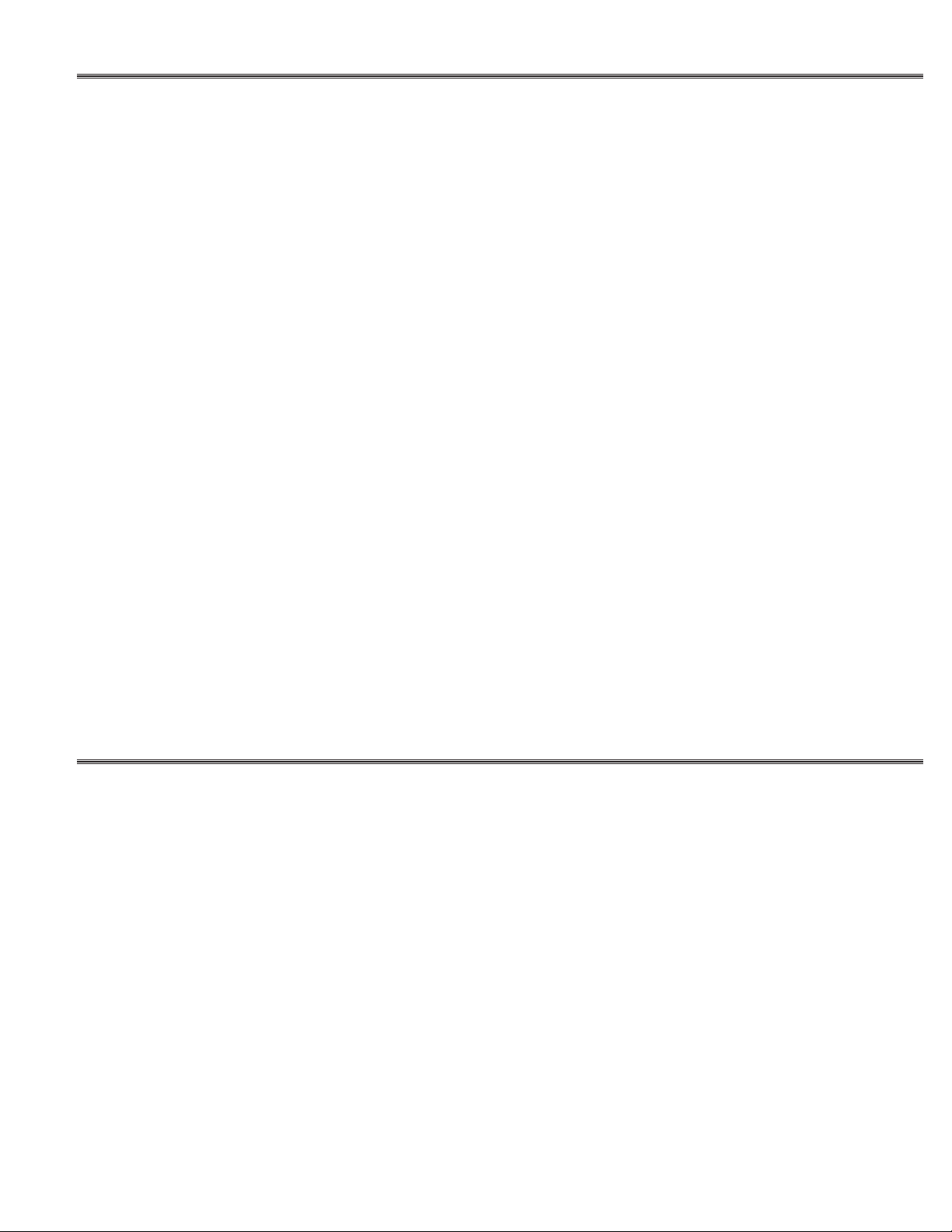

5. Attach the rear brackets to the rear of the

undercarriage with 8 - 3/4” x 2” bolts, 16 - 3/4” washers,

and 8 - 3/4” nuts (1).

2. Remove the front cover on the undercarriage if

necessary.

3. For tractor models 450-550, continue with Step #5.

7. Attach the rear brackets to the rear of the

undercarriage with 8 - 3/4” x 2” bolts, 16 - 3/4” washers,

and 8 - 3/4” nuts (2).

6. Continue with Step #8.

1

2

2

Note: The left bracket (long plate against

undercarriage) attaches on the left side of the

undercarriage and the right bracket on the right

side.

4. For tractor models 350-400, continue with Step #7.

Note: The right bracket (short plate against

undercarriage) attaches on the left side of the

undercarriage and the left bracket on the right side.

8. Position the undercarriage under the tractor and

center on the frame of the tractor.

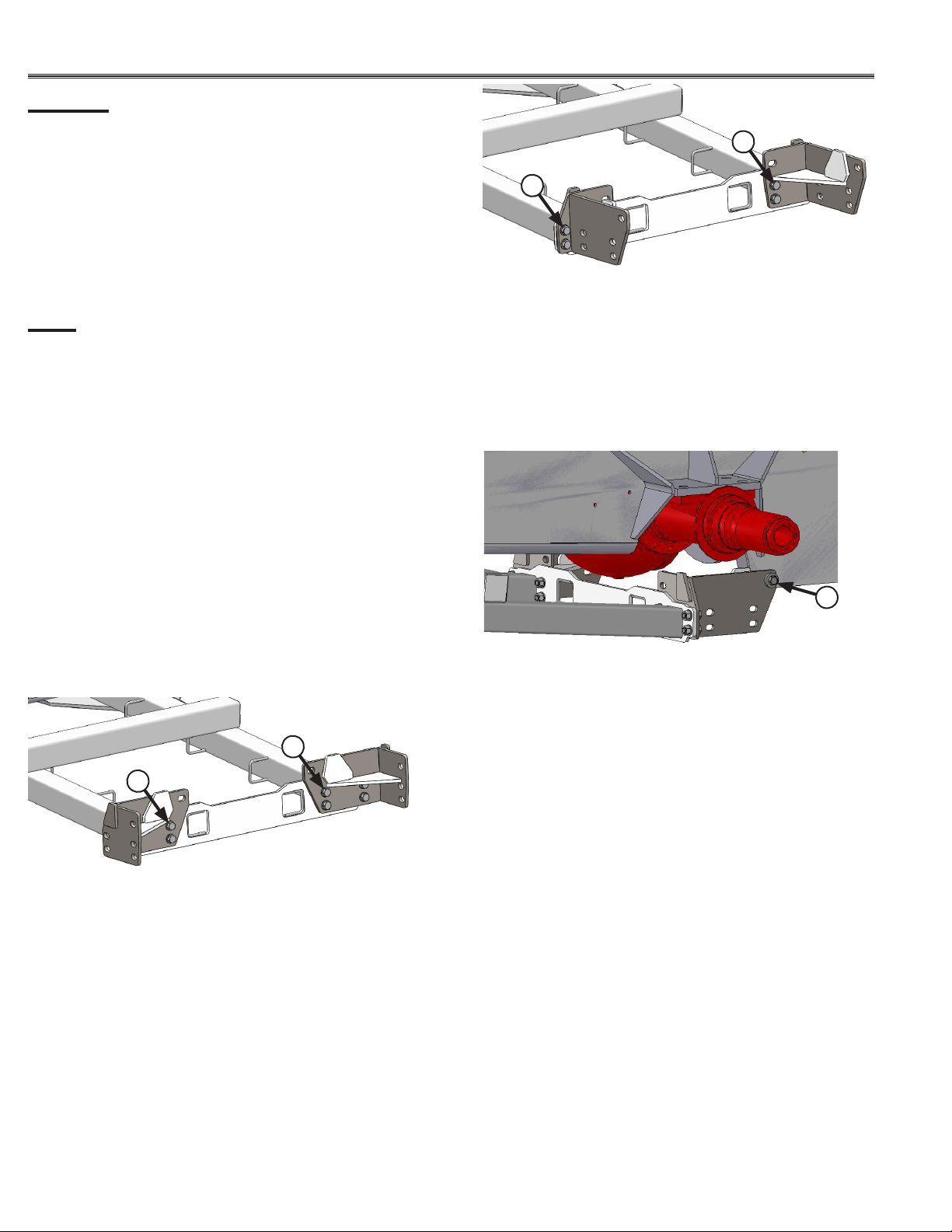

9. Raise the rear of the undercarriage and attach the

rear brackets to the frame of the tractor behind the

front axle with 2 - 20mm x 70mm bolts, 4 - 3/4” ID thick

washers and 2 - 20mm nuts (3).

3

Note: The above photo shows the brackets

installed on a narrow frame but the installation is

the same for the wide frame.

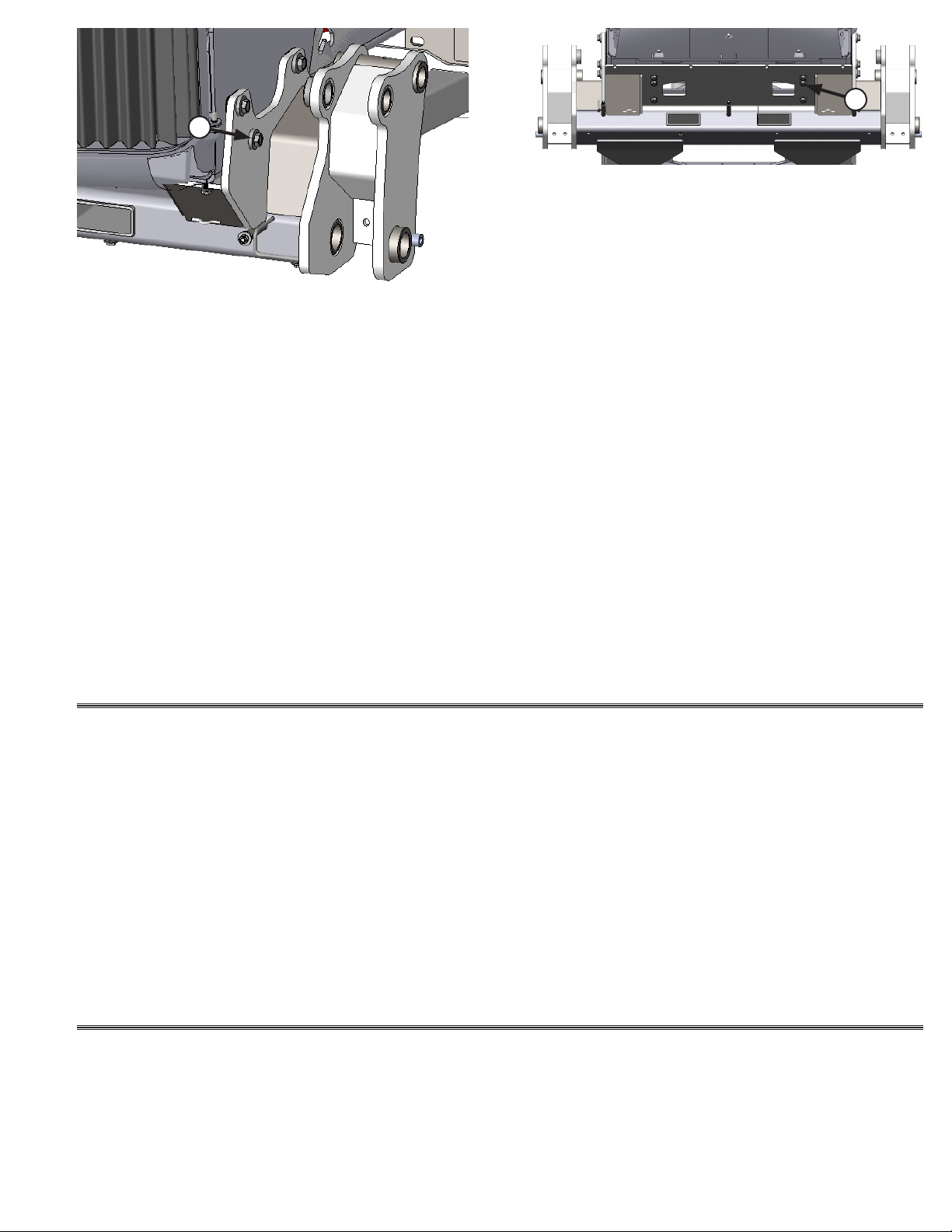

10. Raise the front of the undercarriage until the holes

line up with the holes on the tractor.