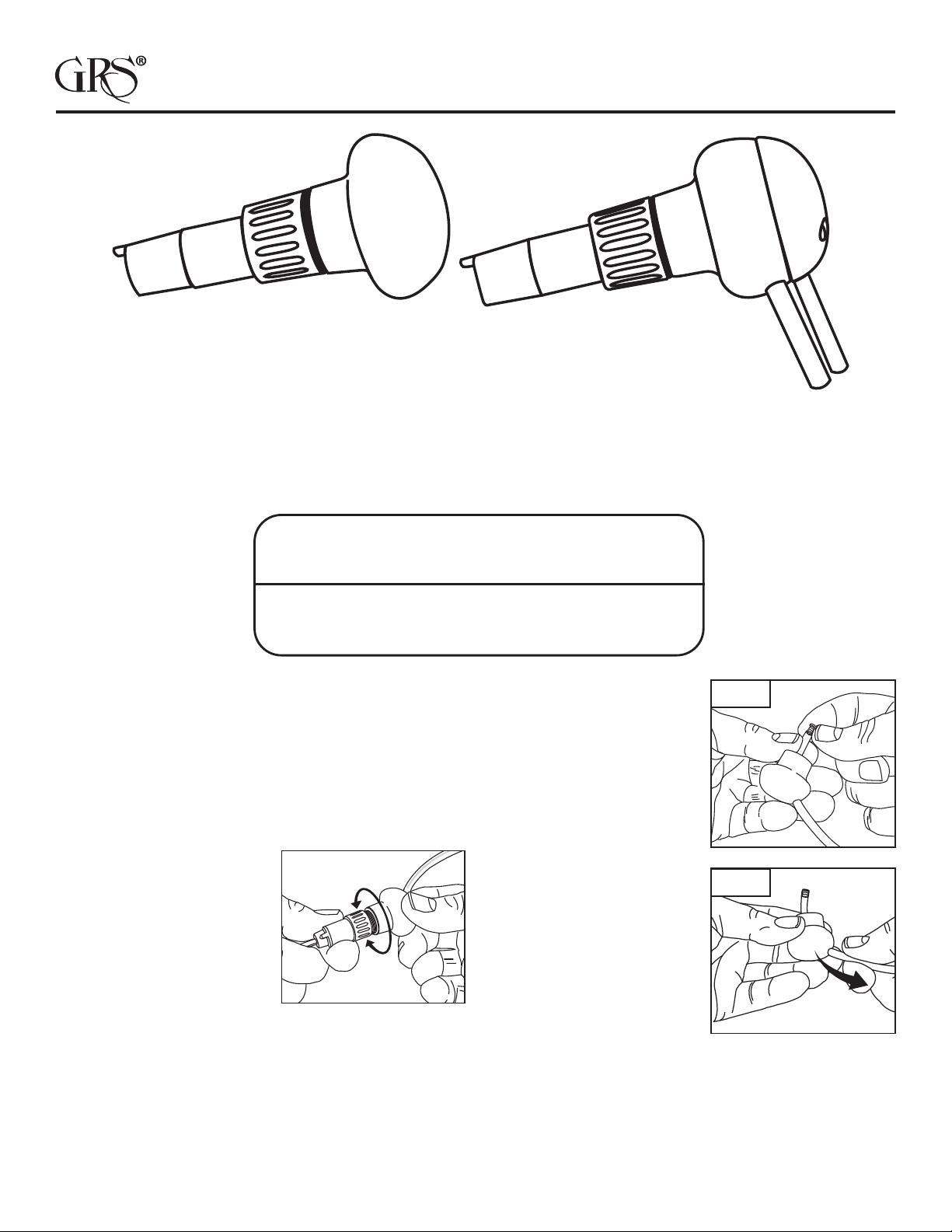

LIT-136 PAGE 2 of 4

Maintenance

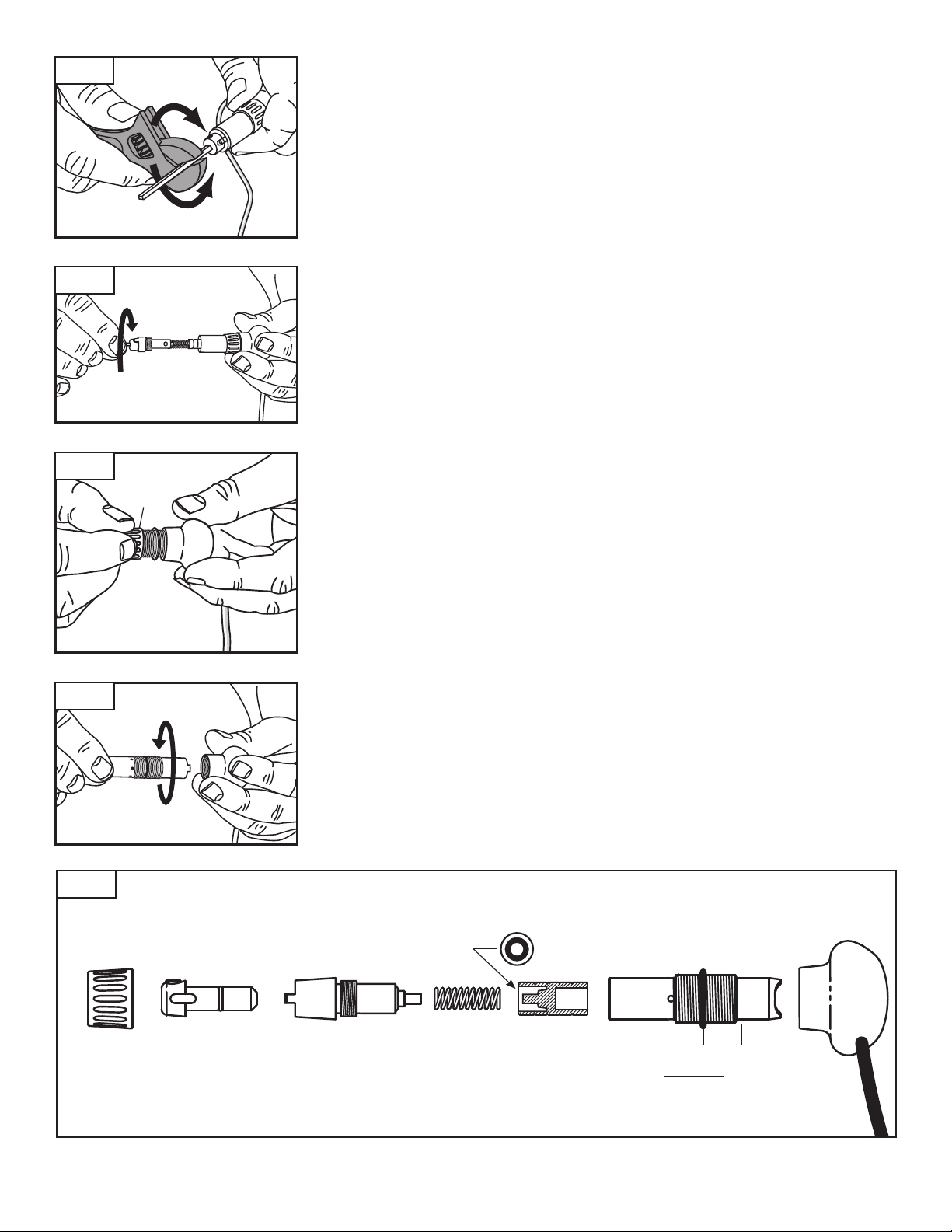

The only basic maintenance for the

GRS Monarch Handpiece is keeping

it clean on the inside. Problems will

occur if oil or moisture gets into

the handpiece, especially on the

piston. If you notice a loss of power

or erratic performance, the FIRST

THING to check is to make sure

the RECEIVER (chuck) IS TIGHT IN

THE HANDPIECE BODY. Using a

crescent wrench or pliers with a graver

inserted in the QC Holder, gently

tighten receiver clockwise (FIG.3) If

erratic performance continues, then

disassemble and clean the handpiece.

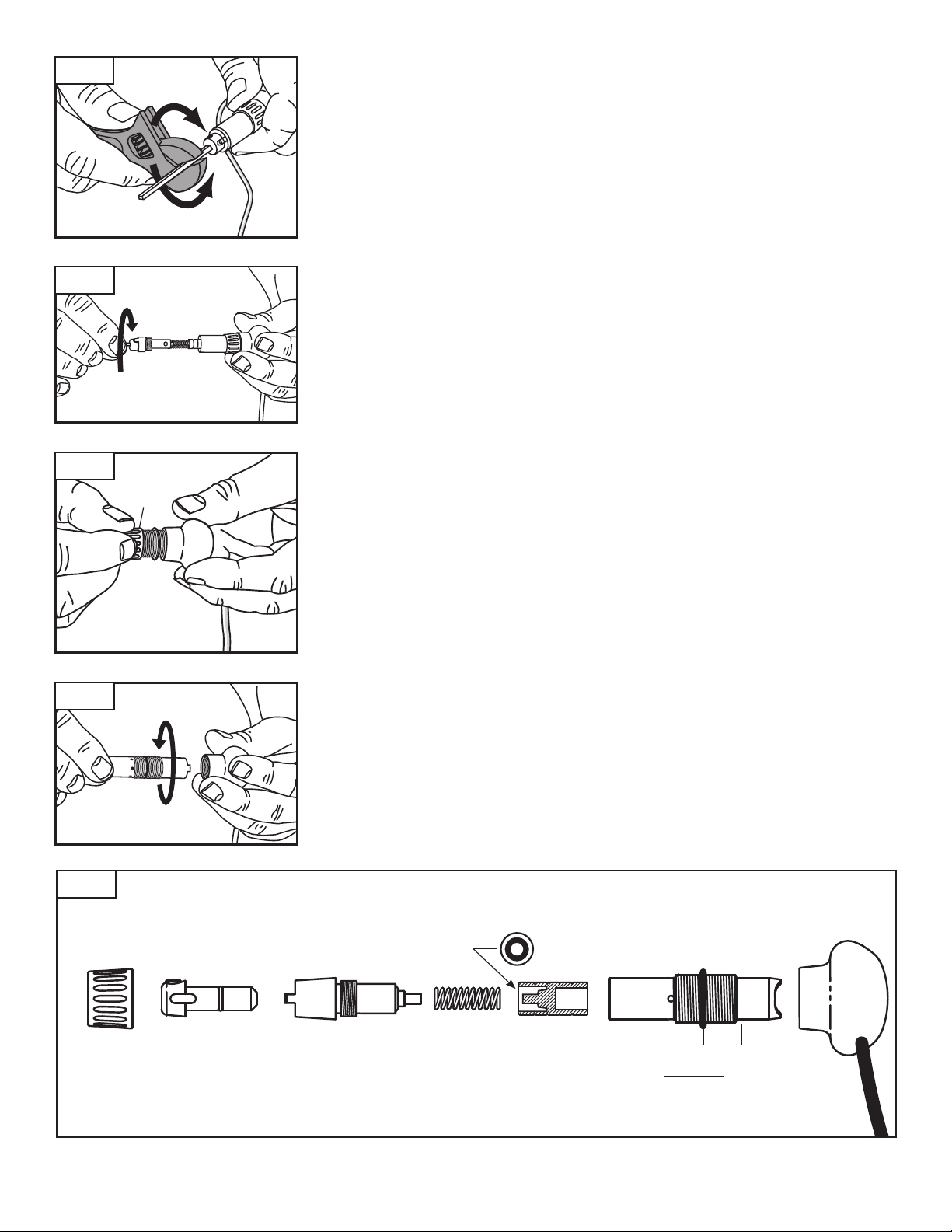

To disassemble the handpiece, use

the crescent wrench or pliers to

grip the graver (FIG. 3) and turn it

counterclockwise to loosen the chuck

retainer. After loosening, turn the

chuck retainer out with your finger tips

(FIG. 4). As you pull out the chuck,

there will be a spring and piston.

Loosen the locking ring and remove

it (FIG. 5). Grip the knob and turn the

handpiece body counter-clockwise

until it is out of the knob body (FIG. 6).

Now, with the handpiece

disassembled, clean the parts with a

NON-residue solvent like denatured

alcohol. Make sure the holes in the

handpiece body are clear from dirt

and debris. DO NOT get moisture

down the air hose. If this happens you

will need to clear and dry it before

reassembly.

Before reassembly, make sure every

thing is completely dry. DO NOT

OIL INSIDE THE HANDPIECE. NO

lubricant is required. Lubricant will

actually decrease performance!

Reassembly Note:

There is an O-ring inside the knob

that makes getting the handpiece

body to thread a little dicult when

reassembling. Use a very small

amount of synthetic lube or non-stick

grease and create a thin film around

the OUTSIDE of the shaft between the

threads and the end (see call out in

FIG. 7).

NOTE: Do NOT use petroleum based

oils - USE ONLY Synthetic oils. Fossil

oils can damage the O-rings.

See “Adjusting the Handpiece” on

page 1 for adjusting graver and hose

position.

VERY LIGHT

synthetic grease lm

END VIEW

Round ANVIL head toward spring

CROSS

SECTION VIEW

QUICK CHANGE HOLDER HINT

Synthetic Lube or non-stick grease on

the shaft of a quick change holder will

make them easier to slip in and out.

FIG. 7

FIG. 6

LOCKING

RING

FIG. 5

FIG. 4

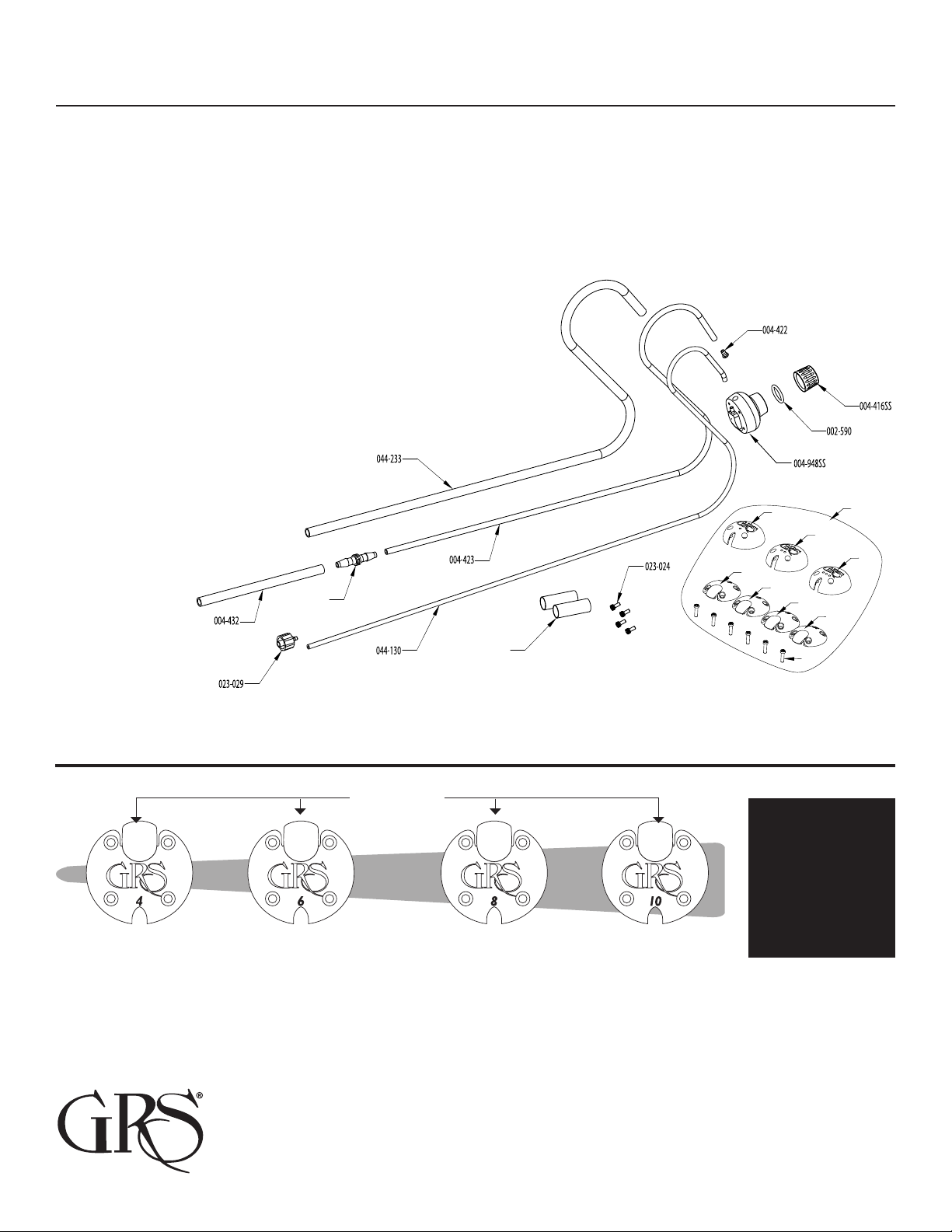

Part # Description

002-950 8-32 X .13

002-605 Allen Wrench

002-590 O-Ring 1/2" ID X 1/16" Wide

004-803 Quick Change Chuck (complete with set screw)

004-415SS Handle Knob

004-416SS Locking Nut

004-417 Handpiece Body

Part # Description

004-929-V2 Chuck Receiver

004-422 Air Hose Retainer

004-423 Air Hose - 1/8" dia. X 38"

004-424 Spring

004-927-V2 Piston / Hammer

022-308 O-Ring 8 mm ID X 1 mm Wide

022-072 Tube Coupling

004-432 Urethane Tubing .170" I.D. X 10"

004-803 (INCLUDES SET SCREW)

004-424

004-432

004-927-V2

004-929-V2

022-308 004-417

002-590

004-415SS

004-423

004-422

022-072

004-416SS

002-590

002-605

002-950

LOOSEN

TURN COUNTERCLOCKWISE

TIGHTEN

TURN CLOCKWISE

FIG. 3