Table of contents................................................................ 3

1About this instruction............................................... 4

1.1 Other applicable documents...................................... 4

1.2 Target group .............................................................. 4

1.3 Storage of the documents.......................................... 4

1.4 Symbols used ............................................................ 4

1.5 Typographical conventions ........................................ 5

1.1 Validity of the instruction............................................ 5

1.6 Type plate.................................................................. 6

2Safety ......................................................................... 7

2.1 Safety measures........................................................ 7

2.2 Technical safety instructions...................................... 8

2.3 Regulations................................................................ 8

2.4 Duties of the specialist installer and/or the

specialist company .................................................... 8

2.5 Duties of the owner/user............................................ 9

2.6 Product-specific safety instructions ........................... 9

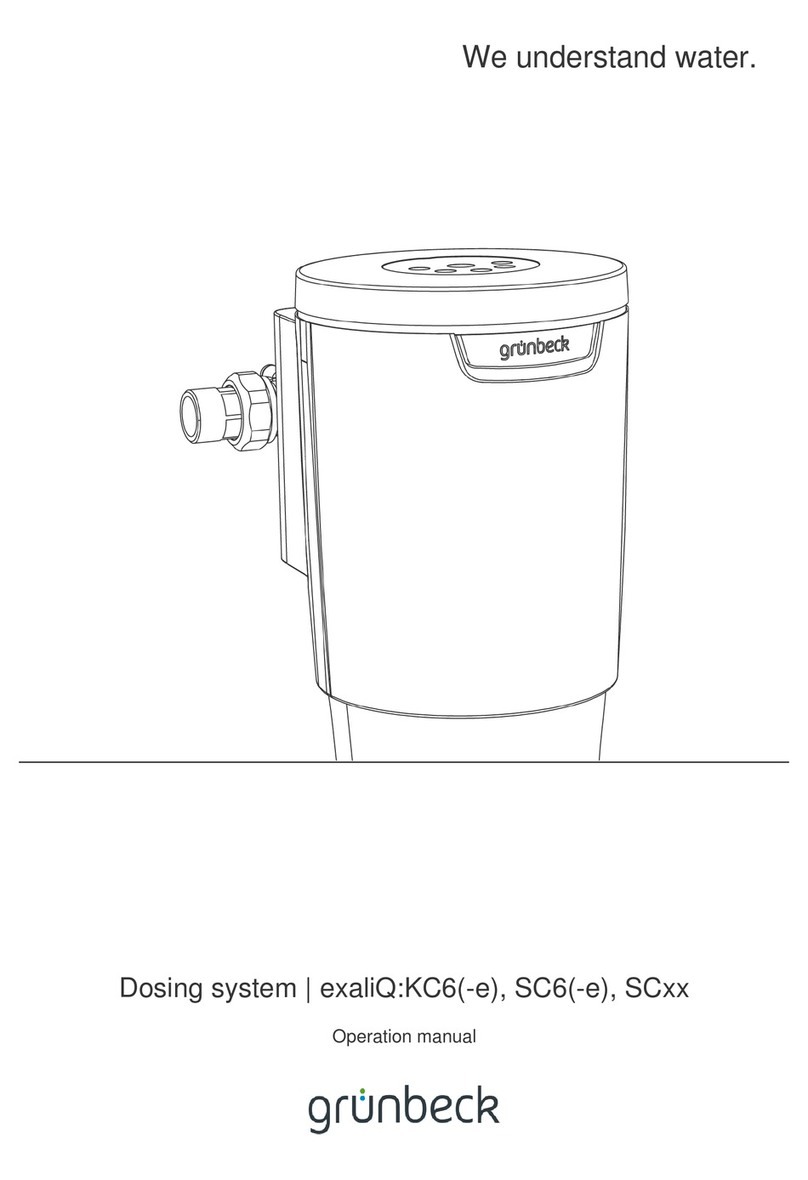

3Product description ................................................ 10

3.1 Intended use............................................................ 10

3.2 Foreseeable misuse ................................................ 10

3.3 Product components................................................ 11

3.4 Functional description.............................................. 11

3.5 Product registration.................................................. 13

3.6 Accessories ............................................................. 13

3.7 Mineral-based solutions........................................... 14

4Installation ............................................................... 16

4.1 Installation examples ............................................... 16

4.2 Requirements with regard to the installation site..... 18

4.3 Checking the scope of supply.................................. 18

4.4 Installing the product................................................ 19

5Start-up .................................................................... 26

5.1 Preparations ............................................................ 26

5.2 Connecting container............................................... 32

5.3 How to start up the product...................................... 35

5.4 Handing over the product to the owner/user............ 35

6Operation ................................................................. 36

6.1 Operating elements and display .............................. 36

6.2 Establishing a connection to Grünbeck

mySettings app........................................................ 38

6.3 Reading out/saving dosing data .............................. 39

6.4 Changing container.................................................. 42

7Cleaning, inspection, maintenance........................45

7.1 Cleaning ...................................................................45

7.2 Intervals ....................................................................46

7.3 Inspection .................................................................46

7.4 Maintenance .............................................................46

7.5 Consumables............................................................47

7.6 Changing mineral-based solution.............................48

7.7 Spare parts ...............................................................49

7.8 Wearing parts ...........................................................49

8Malfunction...............................................................50

8.1 Acknowledge fault ....................................................50

8.2 Troubleshooting........................................................51

9Shut-down and restart.............................................52

9.1 Shut-down ................................................................52

9.2 Restart ......................................................................52

10 Dismantling and disposal .......................................53

10.1 Dismantling...............................................................53

10.2 Disposal....................................................................53

11 Technical specifications .........................................54

11.1 exaliQ:KC6/KC6-e ....................................................54

11.2 exaliQ:SC6/SC6-e ....................................................55

11.3 exaliQ:SC10/SC20/SC30 .........................................56

11.4 Open source licenses...............................................57

12 Operation log............................................................58

1st maintenance ................................................................59

2nd maintenance...............................................................60

3rd maintenance................................................................61

4th maintenance................................................................62

5th maintenance................................................................63

6. Maintenance ..................................................................64

EC Declaration of Conformity ..........................................65

Index...................................................................................66