English (GB) Installation and operating instructions

Original installation and operating instructions

Table of contents

1. General information ........................4

1.1 Hazard statements..........................4

1.2 Notes ..................................4

1.3 References ..............................4

2. Product introduction........................5

2.1 Product description .........................5

2.2 Intended use .............................5

2.3 Applications ..............................5

2.4 Identification..............................5

3. Receiving the product.......................5

3.1 Transporting the product ......................5

3.2 Inspecting the product........................5

3.3 Scope of delivery...........................5

4. Installation requirements .....................6

4.1 Safety regulations ..........................6

4.2 IT mains ................................6

4.3 Aggressive environment ......................6

4.4 Reduced performance under certain conditions ........6

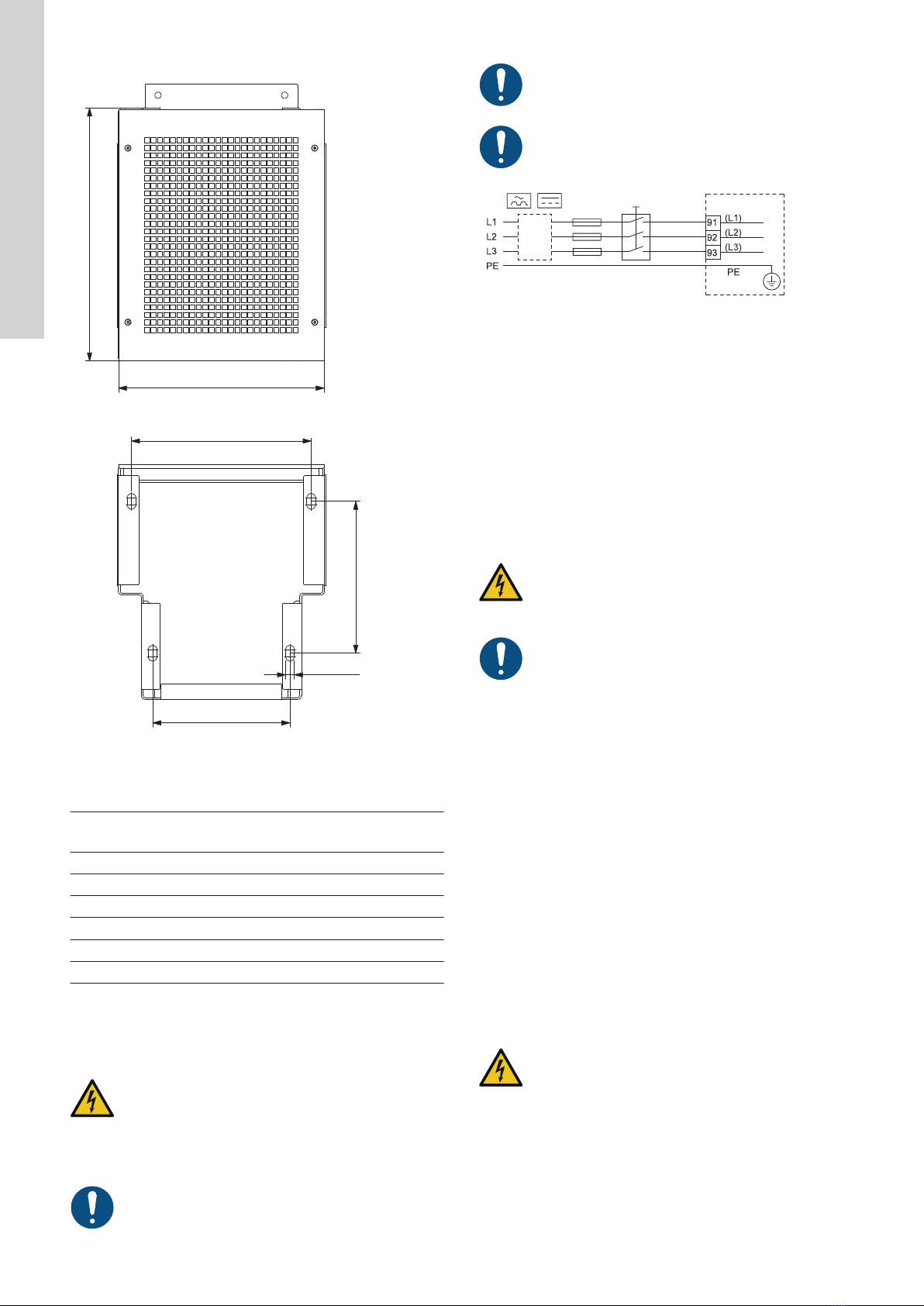

5. Mechanical installation ......................7

5.1 Enclosure types ...........................7

5.2 Space requirements and air circulation .............7

5.3 Mounting................................7

5.4 Mounting on the floor ........................7

6. Electrical connection .......................8

6.1 Electrical protection .........................8

6.2 EMC-correct installation.......................9

6.3 RFI filters ...............................9

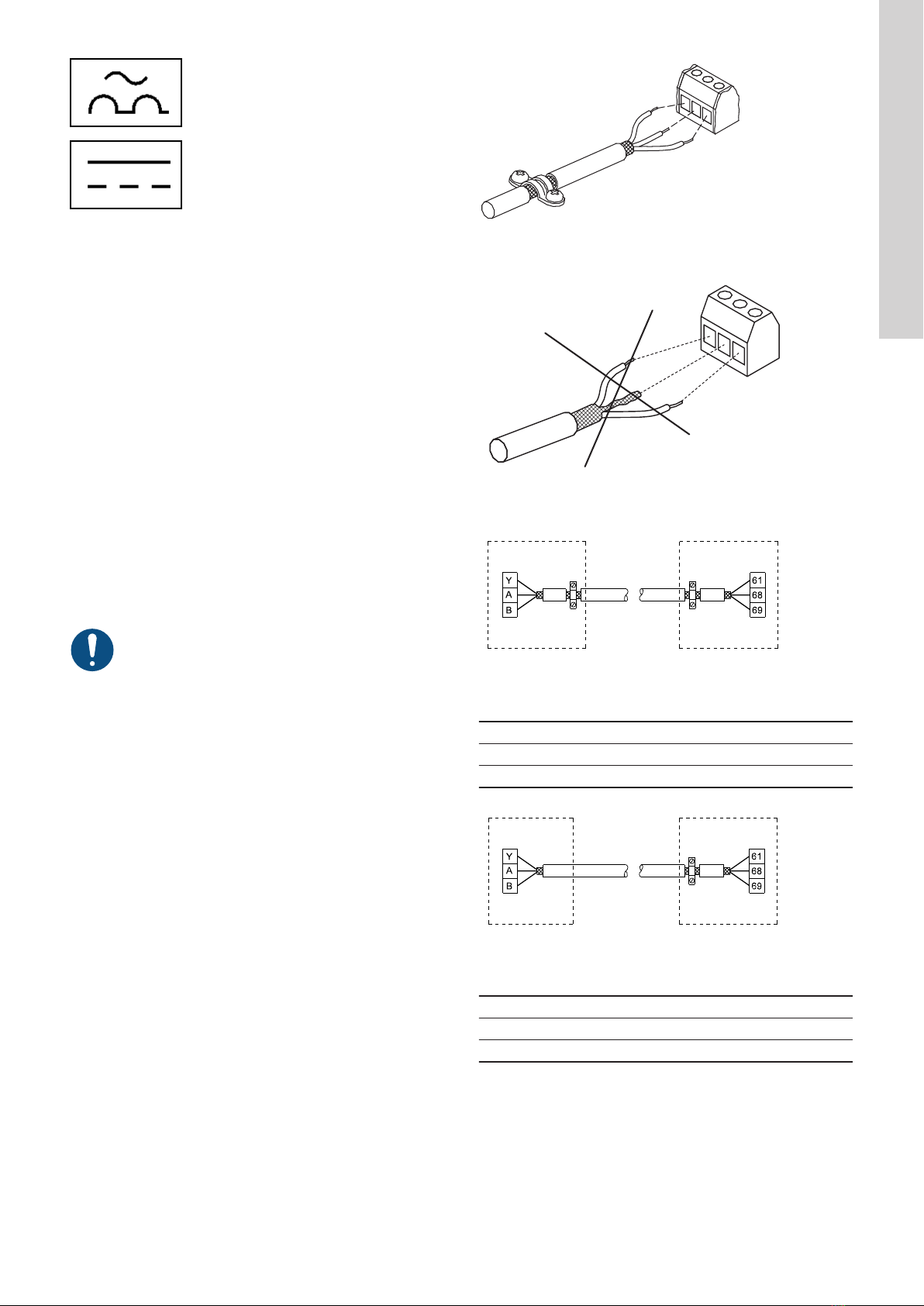

6.4 Motor cable .............................10

6.5 Mains and motor connection ...................10

6.6 STO installation, optional .....................16

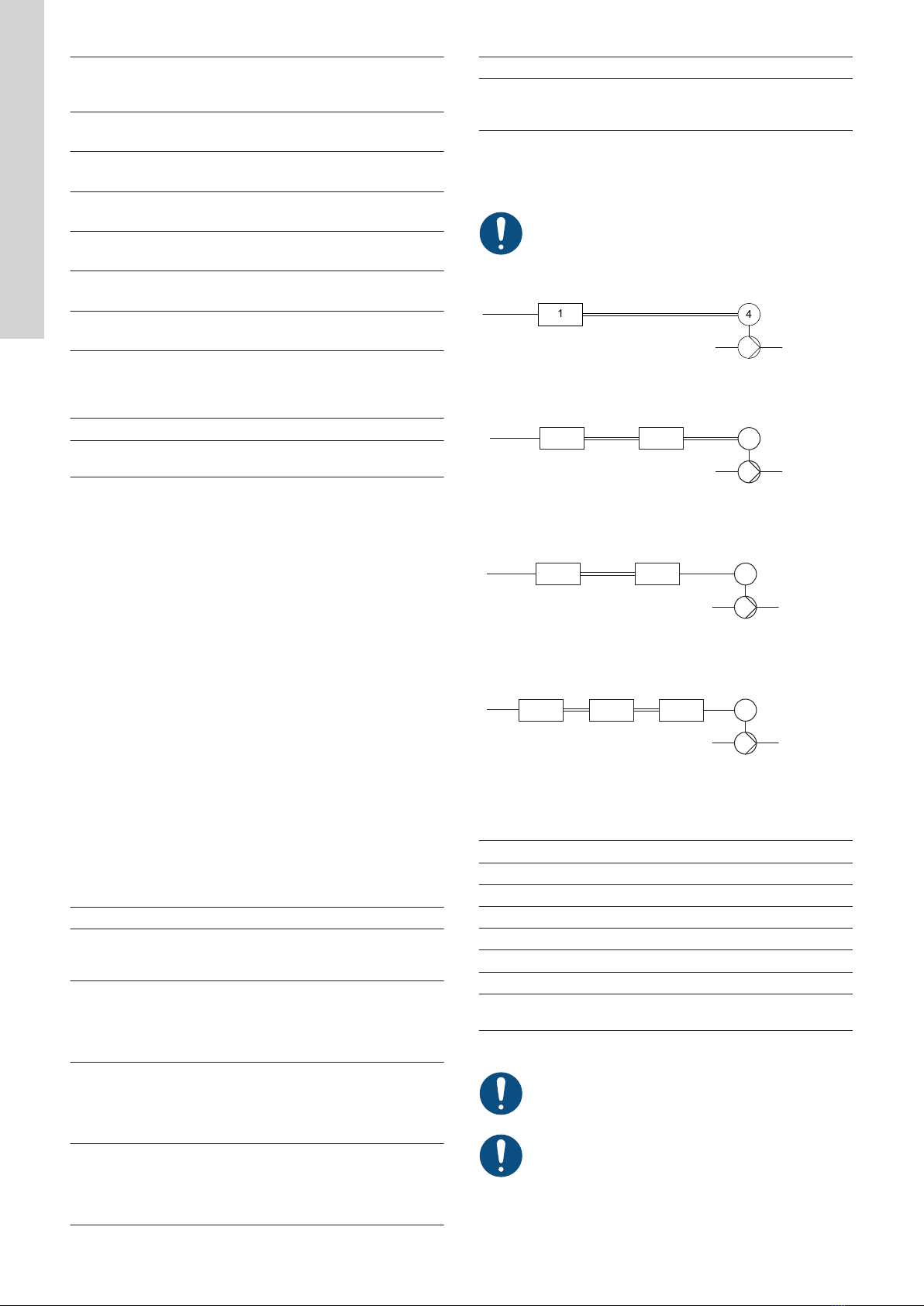

6.7 Connecting the signal terminals .................17

6.8 Connecting the signal relays ...................20

7. Starting up the product .....................22

7.1 Switching on the product .....................22

7.2 Activating the optional STO function ..............22

8. Control functions .........................23

8.1 Operating panel ..........................23

8.2 Menu overview ...........................23

8.3 Menu structure ...........................24

8.4 Operating modes..........................25

8.5 Control modes ...........................25

9. Setting the product........................26

9.1 First-time setup via the startup guide..............26

9.2 Uploading or downloading data .................28

9.3 Setting an asynchronous motor .................28

9.4 Checking the motor rotation direction .............28

9.5 Setting a permanent-magnet motor...............28

9.6 Setting a synchronous reluctance motor............29

9.7 Setting a permanent-magnet assisted synchronous

reluctance motor ..........................29

9.8 Automatic Energy Optimisation (AEO) .............29

9.9 Testing the local control ......................29

9.10 Starting the system ........................29

9.11 Resetting to default settings ...................29

10. Servicing the product ......................30

11. Fault finding the product ....................31

11.1 Overview of warnings and alarms................31

12. Technical data ...........................34

12.1 Enclosure ..............................34

12.2 Operating conditions........................34

12.3 Mechanical data ..........................34

12.4 Electrical data............................40

12.5 Dimensions and weights .....................41

12.6 Miscellaneous data ........................44

13. Disposing of the product ....................45

1. General information

Read this document before you install the product.

Installation and operation must comply with local

regulations and accepted codes of good practice.

1.1 Hazard statements

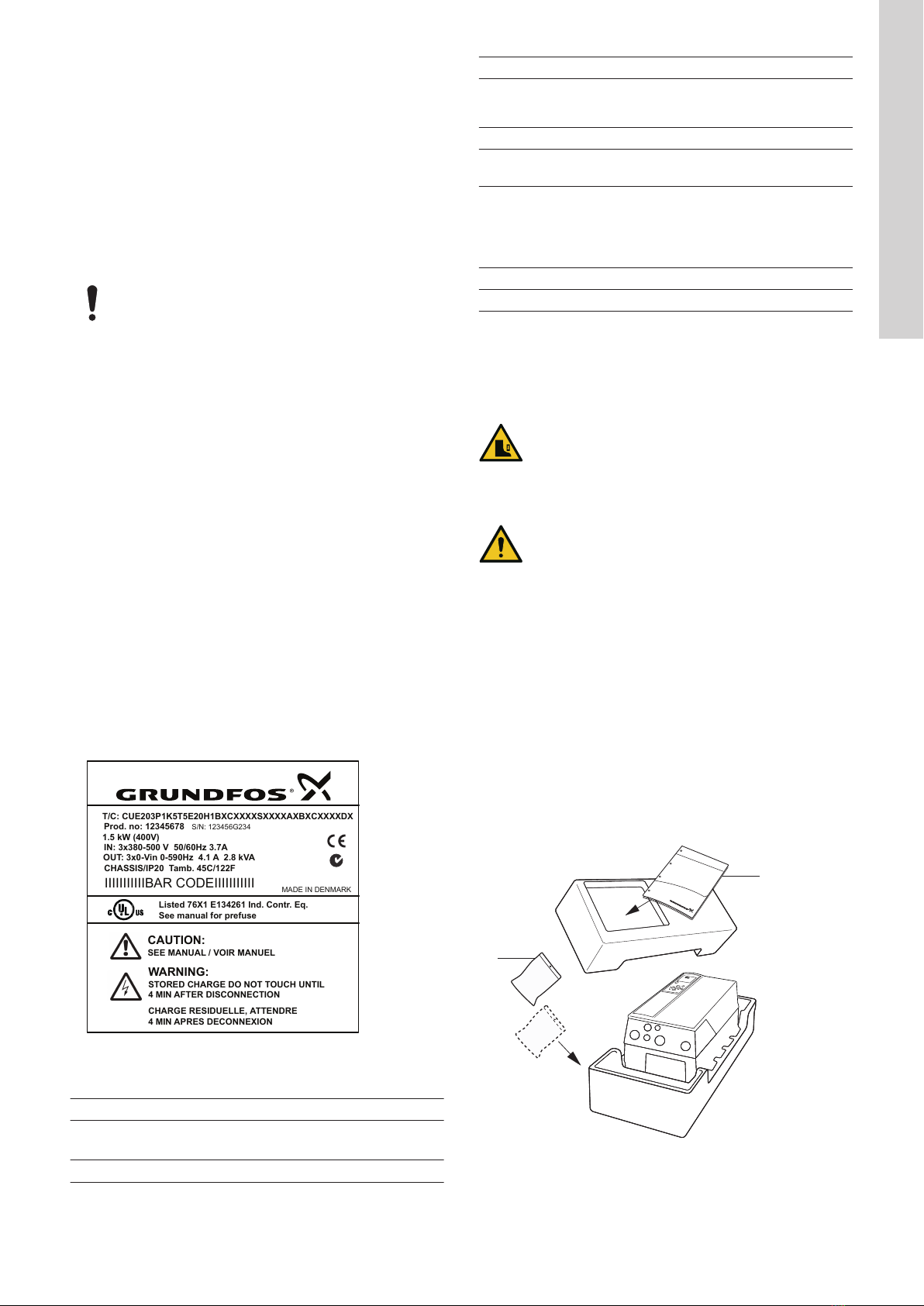

The symbols and hazard statements below may appear in Grundfos

installation and operating instructions, safety instructions and

service instructions.

DANGER

Indicates a hazardous situation which, if not avoided, will

result in death or serious personal injury.

WARNING

Indicates a hazardous situation which, if not avoided,

could result in death or serious personal injury.

CAUTION

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate personal injury.

The hazard statements are structured in the following way:

SIGNAL WORD

Description of the hazard

Consequence of ignoring the warning

• Action to avoid the hazard.

1.2 Notes

The symbols and notes below may appear in Grundfos installation

and operating instructions, safety instructions and service

instructions.

Observe these instructions for explosion-proof products.

A blue or grey circle with a white graphical symbol

indicates that an action must be taken.

A red or grey circle with a diagonal bar, possibly with a

black graphical symbol, indicates that an action must not

be taken or must be stopped.

If these instructions are not observed, it may result in

malfunction or damage to the equipment.

Tips and advice that make the work easier.

1.3 References

Technical documentation for Grundfos CUE:

• The manual contains all information required for putting CUE

into operation.

• The data booklet contains all technical information about the

construction and applications of CUE.

• The service instructions contain all required information for

dismantling and repairing the frequency converter.

Technical documentation is available in Grundfos Product Center at

www.grundfos.com.

4

English (GB)