ORIGINAL INSTRUCTIONS TRANSLATION Pag. di

10 13

VOLTAGE LACKING

In case of electric feeding breaking or if the machine is disconnected from the electric net, this last one will be able to be

restarted only following the starting function, after the electric feeding back or the reconnection to the electric net.

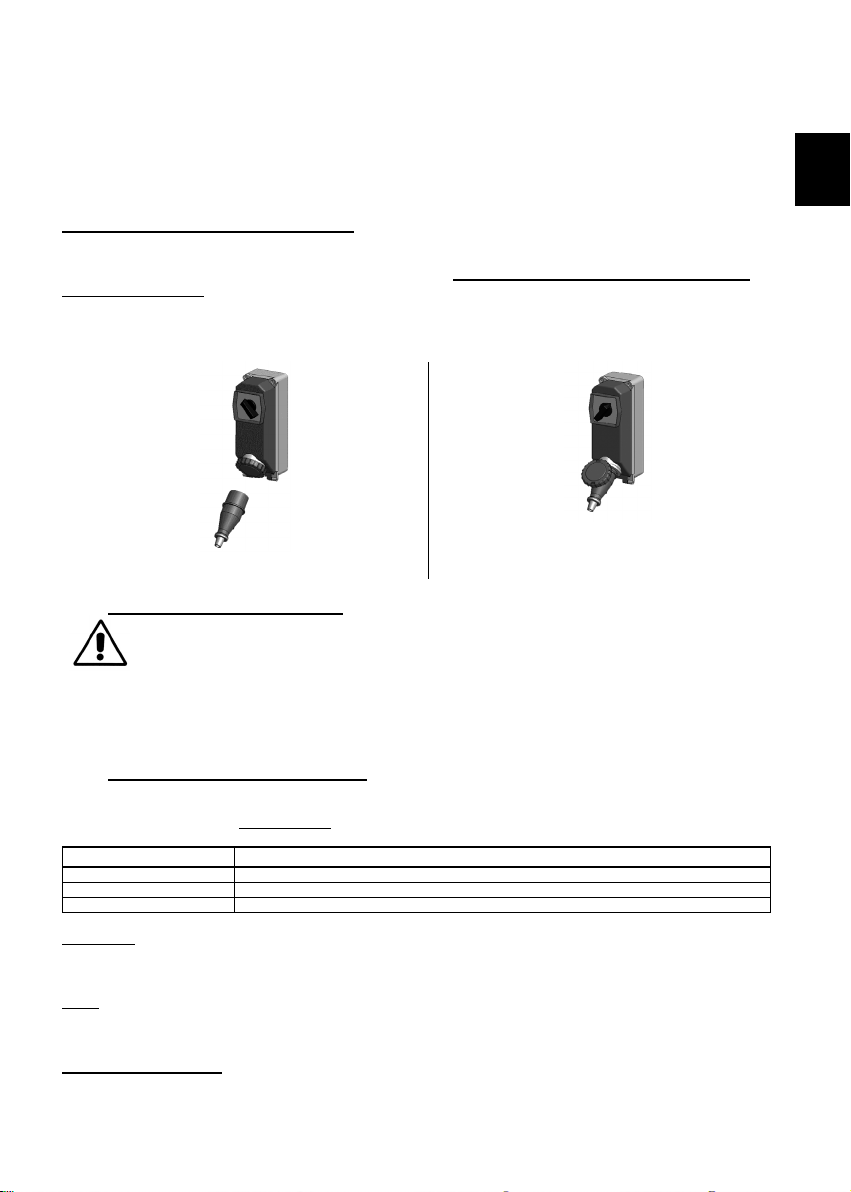

PRESSURE OPENING

Raising for the handle the grater group pressure, the machine stops immediately for the entry infunction of the safeties, motor

brake and micro switch. The machine can be restarted lowering the pressure up to the height that doesn’t allow the fingers

introduction towards the grater roll. If the pressure handle is kept raised for more 30 seconds the machine stops automatically

and the bright indicating light switches off. To perform again the work, restart the starting procedure.

CONTROLS AND VERIFICATIONS BEFORE STARTING

VERIFICATION / CONTROL MODALITY AND CHECKS

Check that:

Extraneous objects aren’t on the machine, inside the grater

mouth and in correspondence of the exile zone of the grated

product

Sight control of the indicated parts, to check of objects or extraneous bodies

lacking as for example different tools, clothes, etc… and that there isn’t

however the food product.

In case of presence, provide with their removal.

Check the cleaning:

of the grater mouth, of the pressure and the grater

roll

of the machine external surface

All indicated parts surfaces, before the machine use must be checked visually

to verify their cleaning.

For the sight check of the grinding group internal parts, provide with its

disassembly.

In case of molds presence or other type of dirtiness, provide with the cleaning

procedure in accordance with the chapter 5 indications

Check the integrity:

of the fixed protections,

of the machine body, of the grater mouth, of the

pressure and the grater roll

All fixed protections, etc.., must perform the function for which have been

foreseen.

Indicated parts sight check to verify their integrity in their surface external

part.

The parts must be however changed at the first erosion signals or breaking.

Check the functionality:

of the control system parts / control about the safety;

of the control devices.

All devices must perform the function for which have been foreseen. Control

directly the devices so that these ones determine the waiting function.

The actuators and all parts must be however changed to the first erosion signals

or breaking.

Check the absence:

of strange noises after the starting

During the functionality checking of the control devices, if there are strange

noises, due for example to a seizing or mechanical breaks, stop immediately

the machine and activate the maintenance service.

Check the absence:

Of oil trails both on the machine support ground

both in the Archimedean screw

Both during the working, both at the end of every work, both in the assembly

moment of the grinding group, check the oil trails absence in the indicated

parts. If there are some fluid drops stop immediately the machine and activate

the maintenance service.

For any intervention type or for the parts change that are damaged, activate the maintenance service. The possible change

must happen with manufacturer original products or at least of quality, safety and equivalent characteristics. For analysis

contact the Authorized Assistance Center.

PUT IN FUNCTION

The machine operator can put in function the machine following in order the under reported indications:

1. Controls positive result for the preparation preliminary operations,

2. Controls positive result for the electric feeding,

3. Plug connection in opportune current socket,

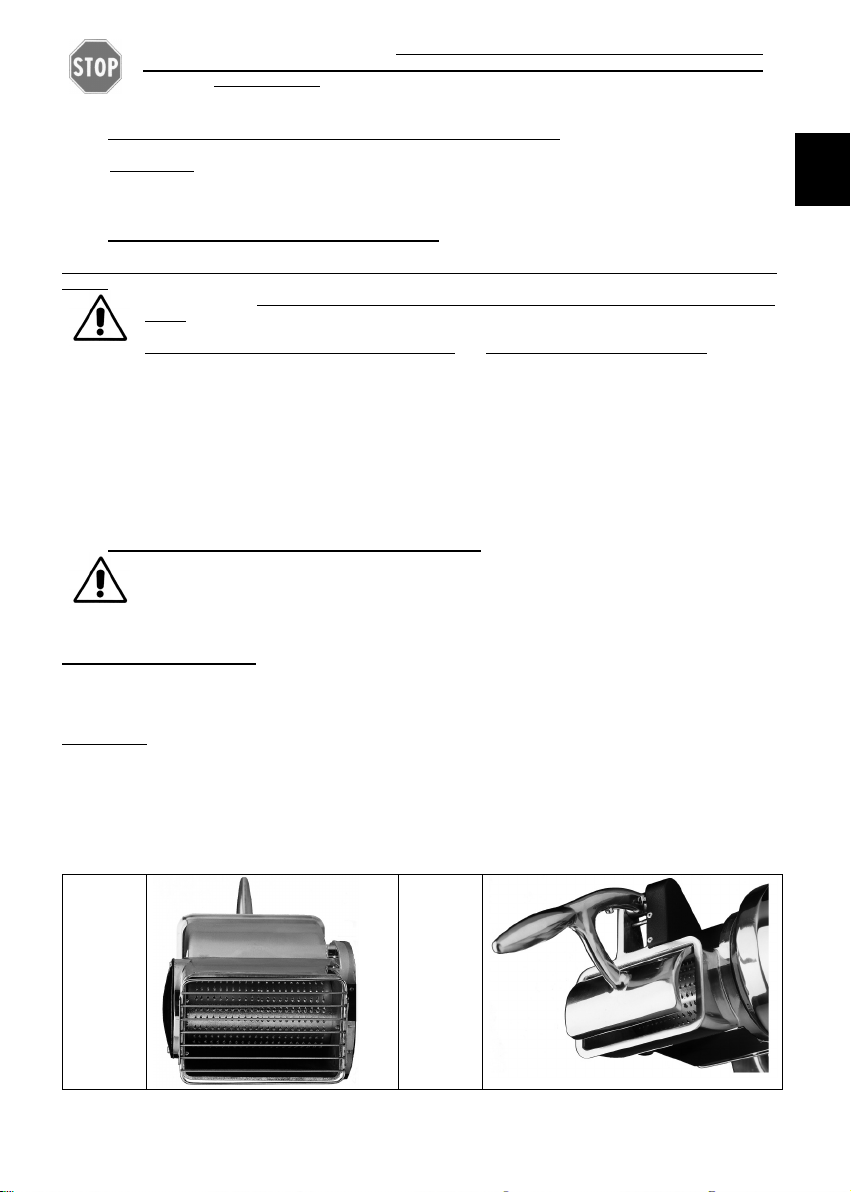

4. For the functioning of the GRATER GROUP:

a. Checks positive result for the grater roll correct rotation,

b. Checks positive result / verifications before the starting,

c. Finalized checks positive result and verify the all safety conditions respect,

d. Place a gathering basin in the machine anterior zone in correspondence of the grated product exit zone,

e. Put in the machine left side and start the machine acting the control device of start “I”,

f. Introduce manually the food product within the grater mouth and drive it towards the grater roll lowering the

pressure roll,

g. At the end of the food product introduction, or when in the basins the product is not more left, stop the machine

acting the control device of stop “0”.

It is recommended to make not work the machine in vain, without the food product.

SWITCHING OFF

In succession, the switching off must follow what here under indicated:

1. Before the switching off wait the food product exile conclusion from the grater mouth inferior zone;

2. Stop the machine acting the stop control device “0”,

3. Disconnect the machine plug from the feeding socket,

ENGLISH