AWT35‐500349|June2009 Page1

Table of Contents

1.0INSTALLATION................................................................................................................................................3

1.1DESKTOPMOUNTING................................................................................................................................................3

1.2PANELMOUNTING(350DIECASTONLY).....................................................................................................................3

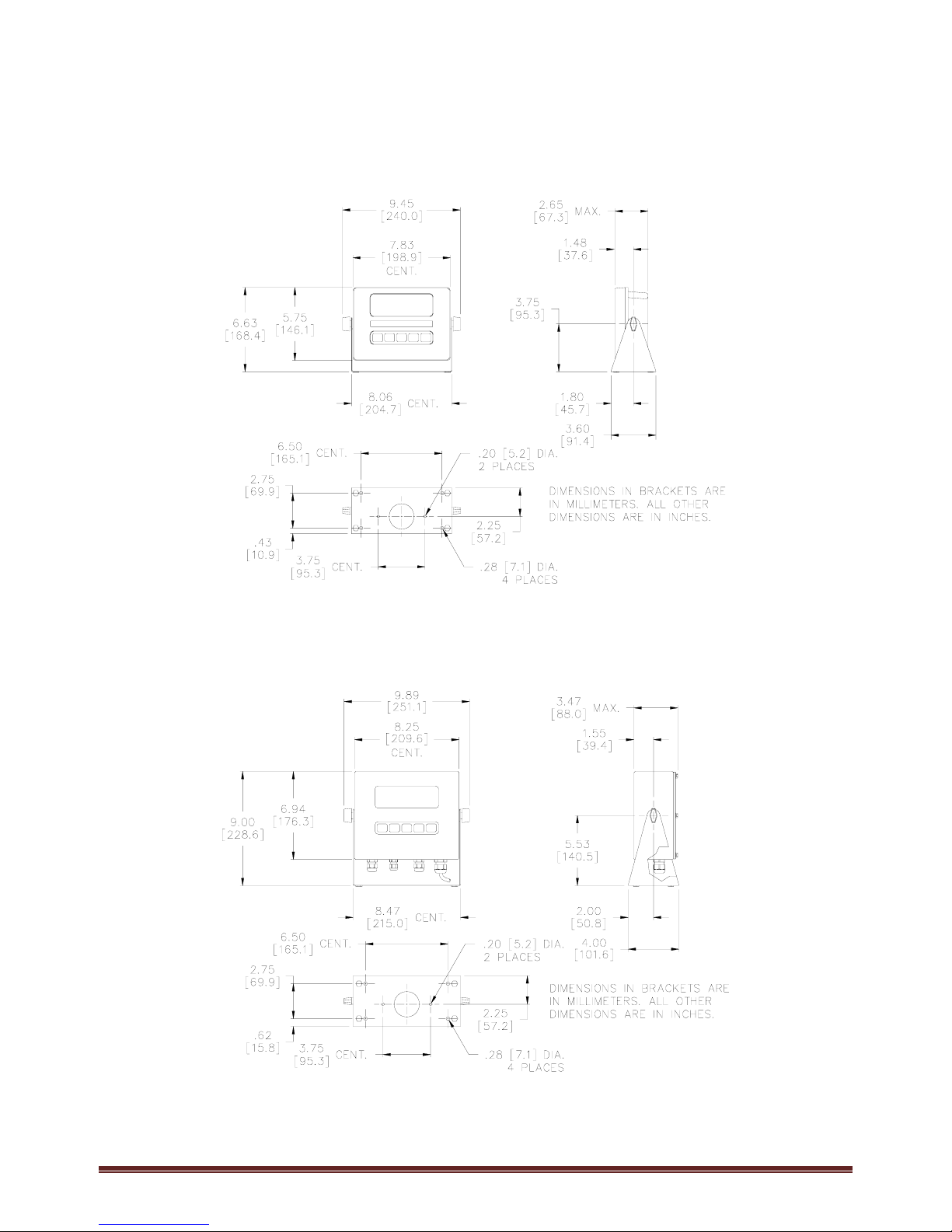

1.3OUTLINEDRAWINGS..................................................................................................................................................4

1.3.1350DieCast................................................................................................................................................4

1.3.2350StainlessSteel......................................................................................................................................4

1.3.3355StainlessSteel......................................................................................................................................5

1.4ACANDDCPOWER..................................................................................................................................................5

1.4.1BatteryOperated........................................................................................................................................5

1.4.2ACOperated................................................................................................................................................5

2.0KEYPADANDDISPLAY.....................................................................................................................................6

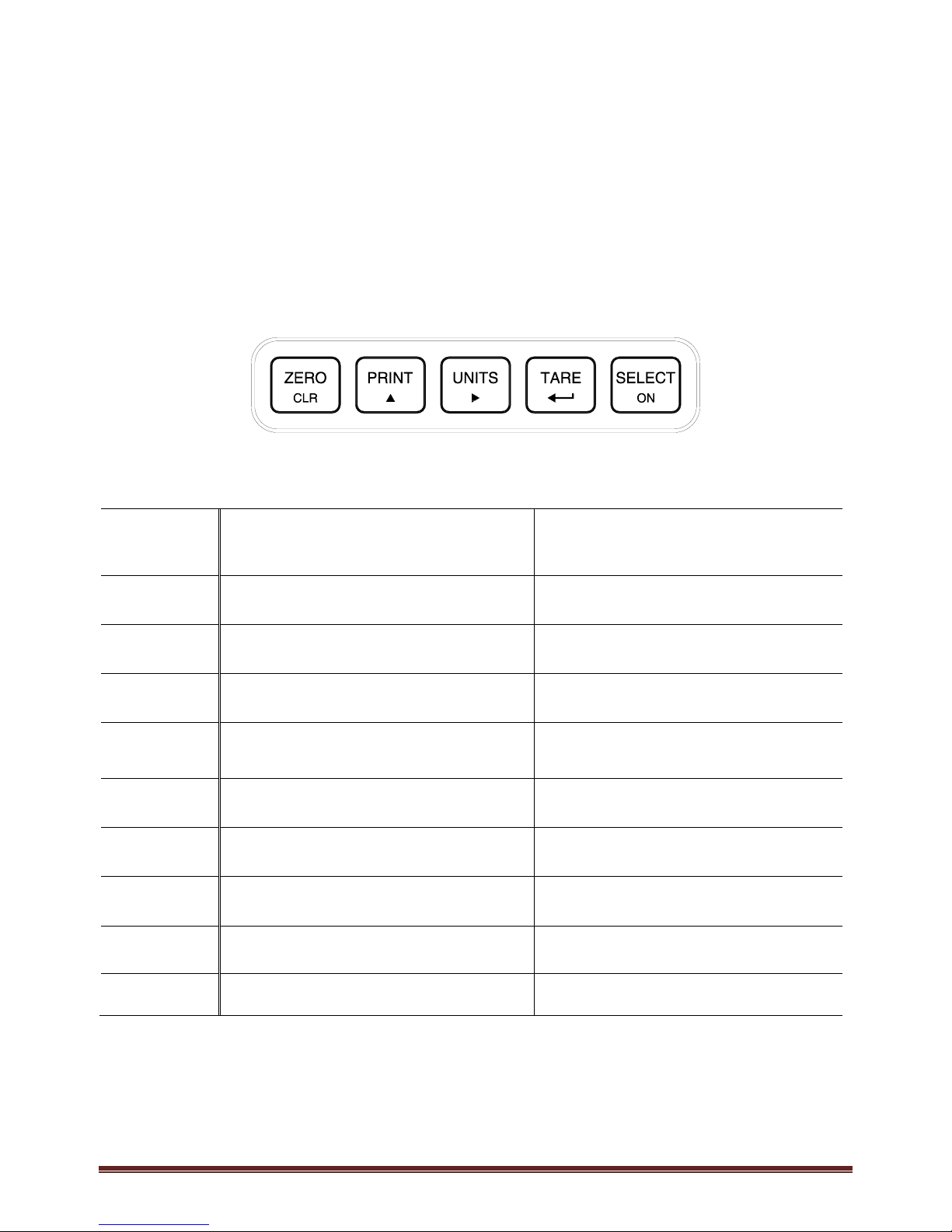

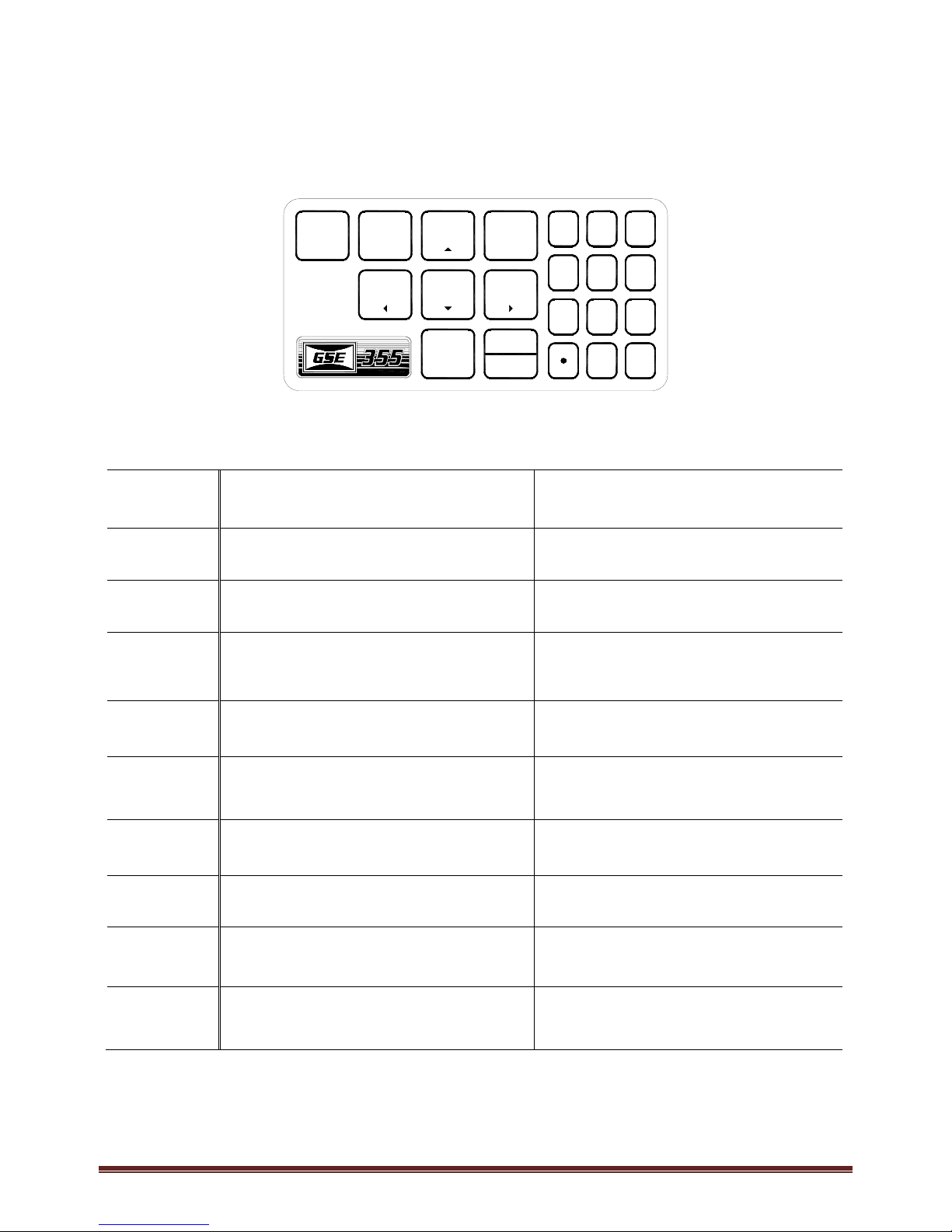

2.1KEYPADS.................................................................................................................................................................6

2.1.1Model350Keypad......................................................................................................................................6

2.1.2Model355Keypad......................................................................................................................................7

2.1.3WeighModeFunctions...............................................................................................................................8

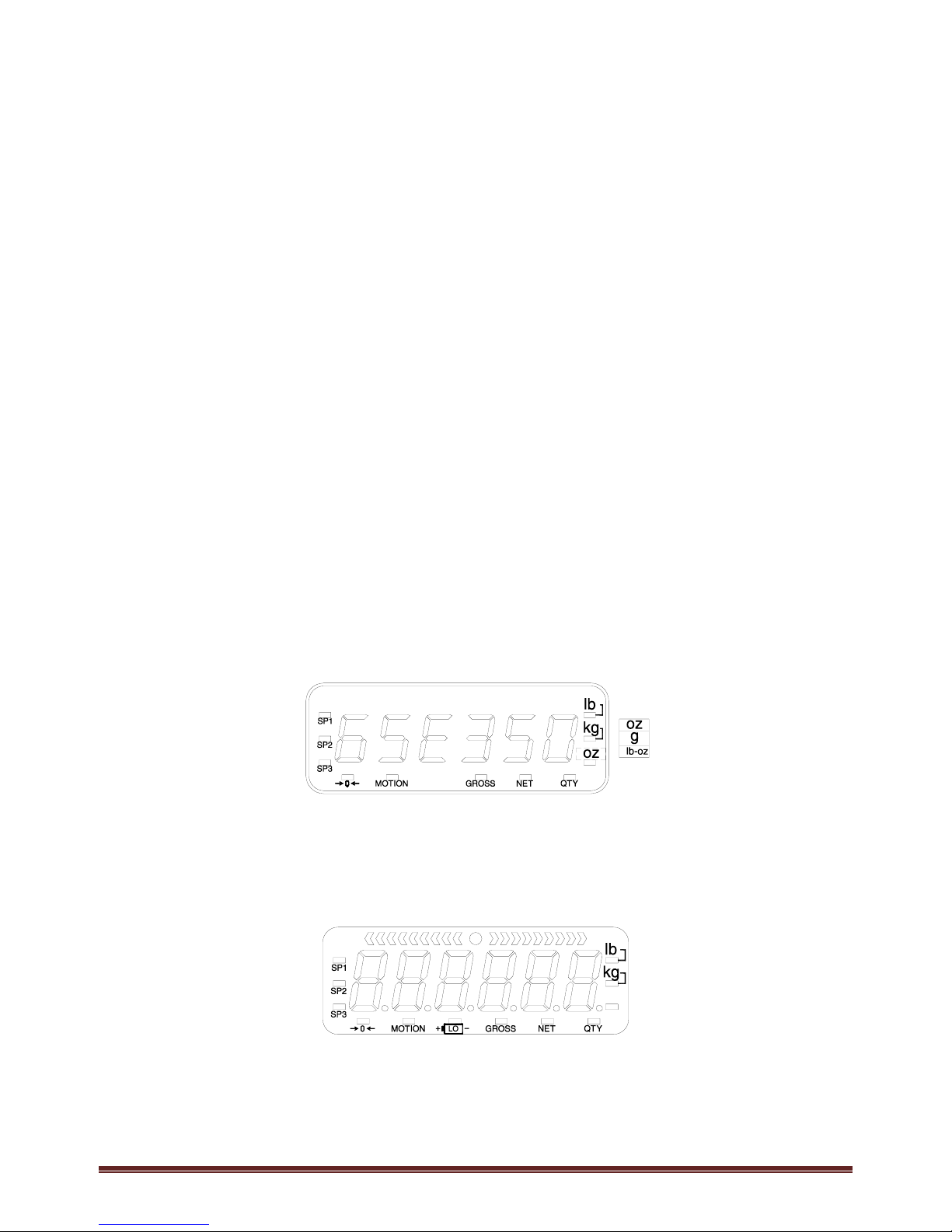

2.2DISPLAYS.................................................................................................................................................................8

2.2.1LED..............................................................................................................................................................8

2.2.2LCD..............................................................................................................................................................8

2.3REMOTEDISPLAY......................................................................................................................................................9

3.0OPERATION..................................................................................................................................................10

3.1ENTERINGATAREVALUE(MODEL350)......................................................................................................................10

3.2ENTERINGATAREVALUE(MODEL355)......................................................................................................................10

3.3ENTERANIDNUMBER.............................................................................................................................................10

3.4SETTIME&DATE...................................................................................................................................................11

3.4.1Model350.................................................................................................................................................11

3.4.2Model355.................................................................................................................................................11

3.5PARTSCOUNTING...................................................................................................................................................12

3.5.1Model350.................................................................................................................................................12

3.5.2Model355.................................................................................................................................................13

3.5.3Viewtheaveragepieceweight.................................................................................................................13

3.6PERCENTAGECHECKWEIGH.......................................................................................................................................14

3.6.1EnteraTargetValue.................................................................................................................................14

3.6.2StartCheckweighing.................................................................................................................................15

3.7FILL......................................................................................................................................................................15

3.7.1EnteraTargetValue.................................................................................................................................15

3.7.2StartFill.....................................................................................................................................................16

3.7.3FillExample...............................................................................................................................................16

3.8BATCH..................................................................................................................................................................17

3.8.1EnteraTarget...........................................................................................................................................17

3.8.2StartBatch................................................................................................................................................18

3.8.3BatchExample..........................................................................................................................................18

3.9DISCHARGE............................................................................................................................................................19

3.9.1EnteraTarget...........................................................................................................................................19

3.9.2Pre‐acts.....................................................................................................................................................20

3.9.3StartDischarge.........................................................................................................................................20