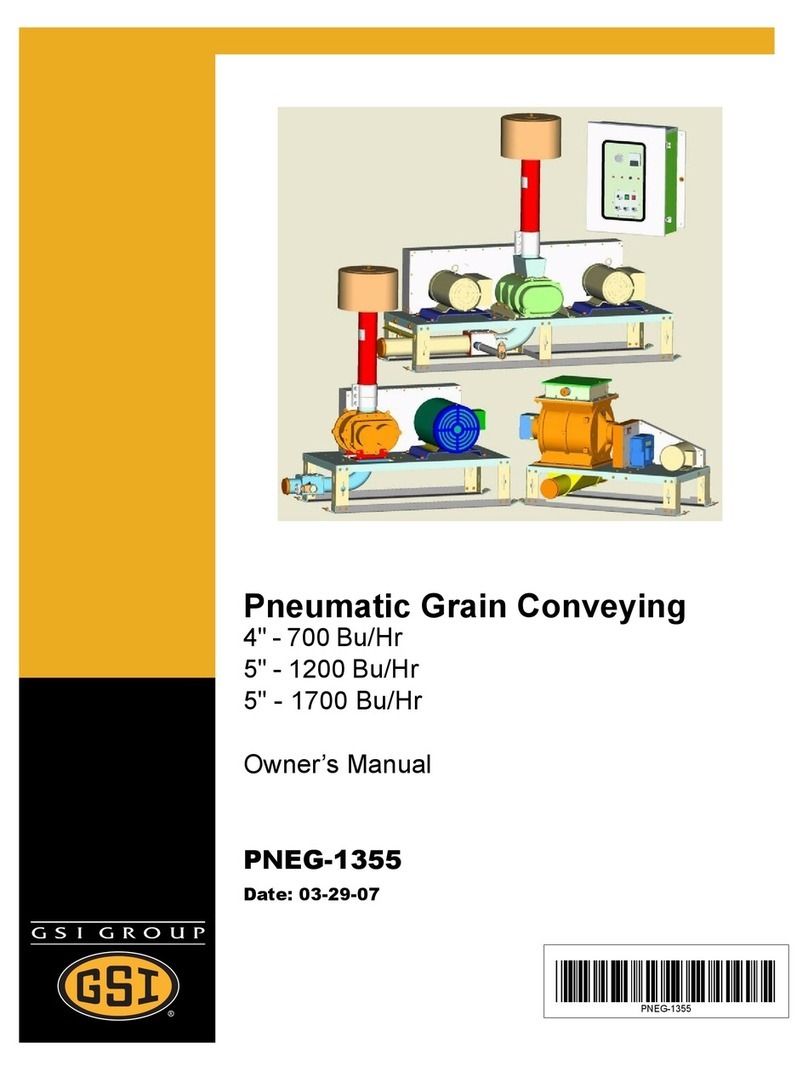

Pneg-1563 4" & 5" Air Systems '07 Production 3

Table of Contents

Contents

Chapter 1 Safety .................................................................................................................................. 5

Safety Guidelines ................................................................................................................5

Chapter 2 Decals ................................................................................................................................. 9

Chapter 3 Maintenance ..................................................................................................................... 11

Maintenance Schedule ......................................................................................................11

Chapter 4 Air System ........................................................................................................................ 12

Air System Capacities (Dry Shelled Corn) ........................................................................12

Capacity Chart (4" & 5" Systems) ..................................................................................... 12

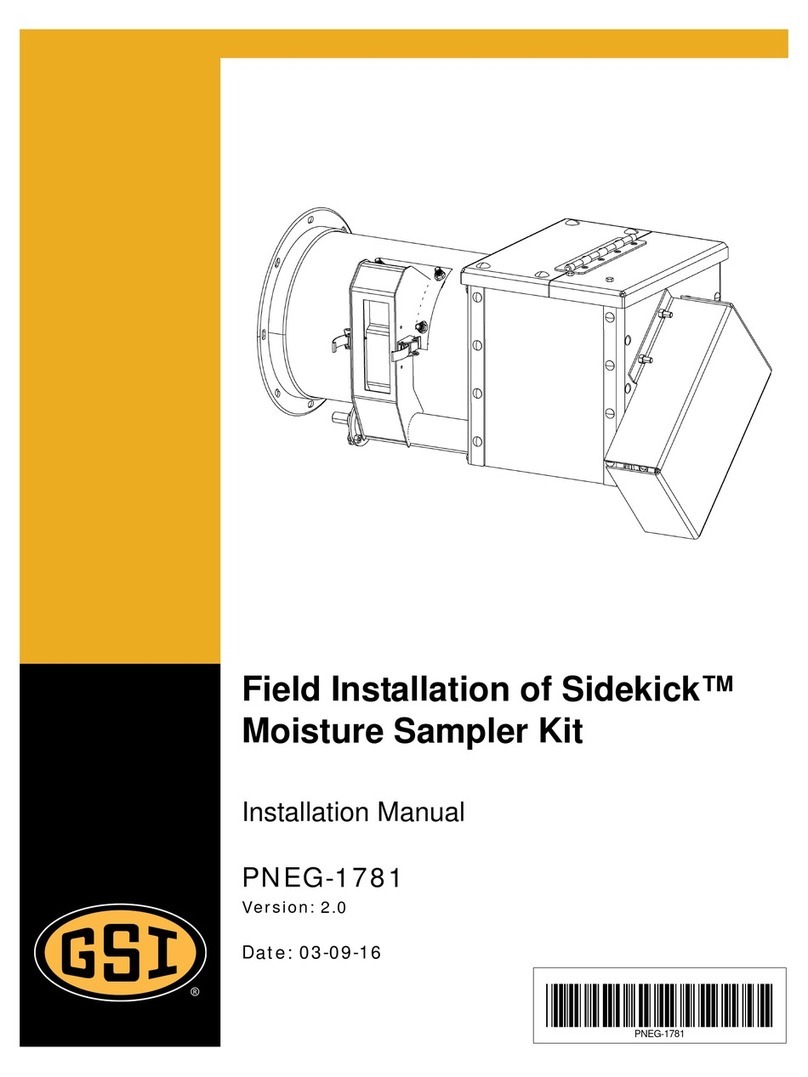

Chapter 5 Installation ....................................................................................................................... 13

Air System Installation Instructions ...................................................................................13

Air System Capacities (Dry Shelled Corn) ........................................................................14

Air System Tubing Dimensions .........................................................................................15

Chapter 6 Dimensions ......................................................................................................................16

Elbow Angle Measurements .............................................................................................16

Chapter 7 Assembly ......................................................................................................................... 17

Air System Set-Up Procedures .........................................................................................17

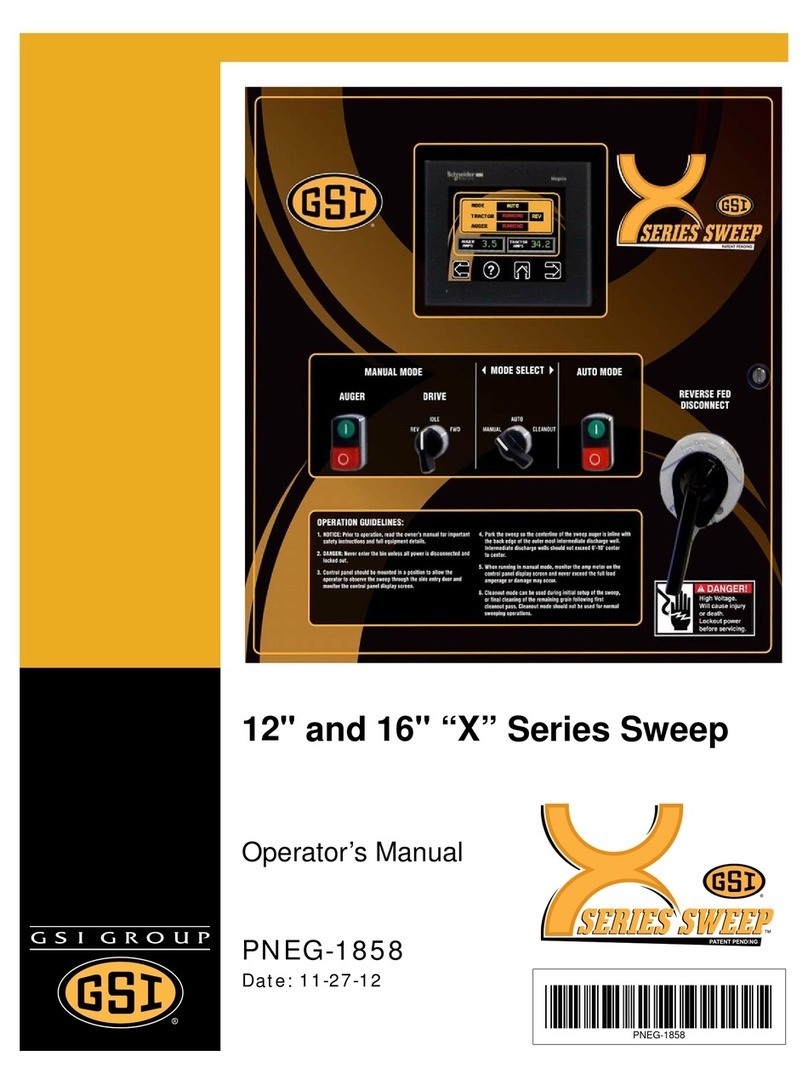

Air System Control Box Definitions ...................................................................................20

Control Overview ...............................................................................................................20

Chapter 8 O/L CHART ....................................................................................................................... 23

4" & 5" Overload Set Chart ................................................................................................ 23

Chapter 9 Wiring ...............................................................................................................................24

Schematic - 230V-1PH ...................................................................................................... 24

Schematic - 230V/460V/575V-3PH ...................................................................................25

Schematic - Twin Air Systems ..........................................................................................26

Chapter 10 Operation and Management ......................................................................................... 27

Control Box Operational Procedures ...............................................................................27

Air System Operation Guidelines .................................................................................... 28

Chapter 11 Hook-Up Diagrams ........................................................................................................30