3

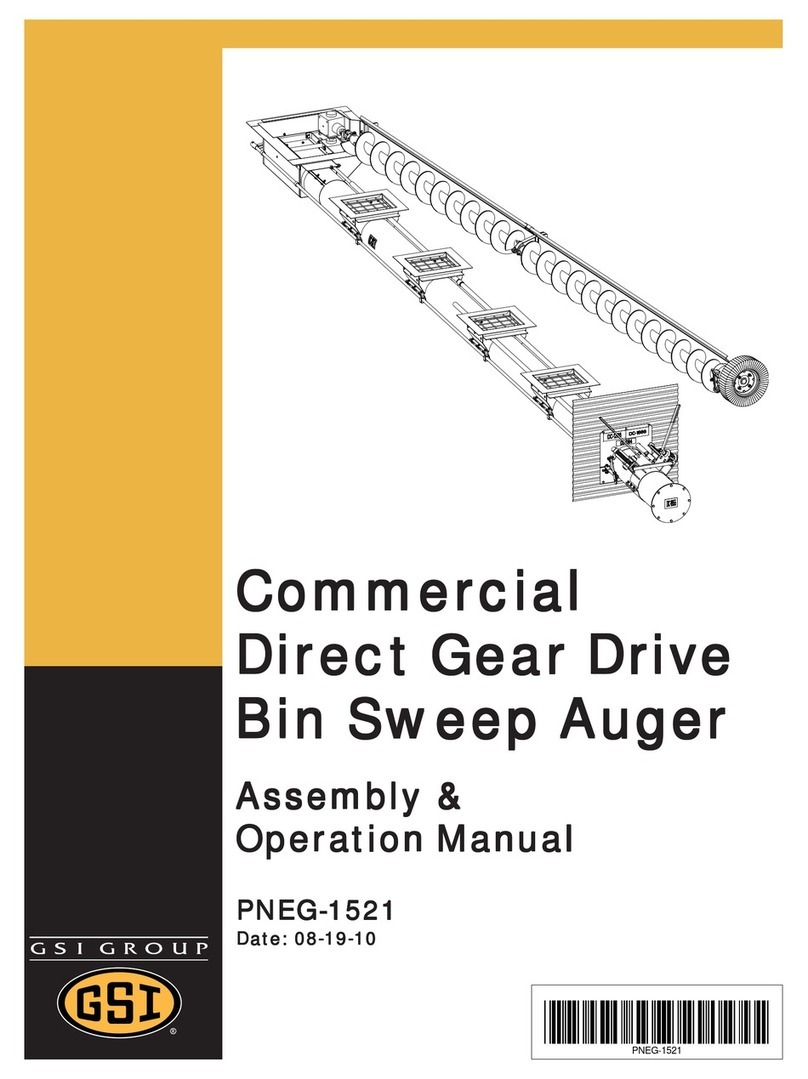

PNEG-1421 DirectGearDriveBinSweepAuger

Table of Contents

Introduction..............................................................................................................4

SafetyGuidelines....................................................................................................5

SafetyInstructions ................................................................................................6-8

OperatorQualifications ...........................................................................................9

Safety1st Program ...............................................................................................10

Decals .............................................................................................................11-12

Installation Section

Power Sweeps in Bins with Concrete Floors ................................................13

Power Sweeps in Bins with Raised Metal Floors ..........................................14

IntermediateWellInstallation.........................................................................15

UnloadTubeInstallation ...........................................................................16-17

BinFlangeInstructions..................................................................................18

CenterWellSlideGateAssembly .................................................................19

ControlLeverInstructions(6"Systems).........................................................19

Rack& Pinion Instructions(8" & 10"Systems)..............................................20

ClutchControlInstructions.............................................................................21

UnloadTubeFlightInstructions .....................................................................22

SweepFlightInstructions .........................................................................23-25

SweepWheelInstructions.............................................................................26

PowerRecommendations.....................................................................................27

BeforeFilling the Bin .............................................................................................28

PerformPre-StartChecks .....................................................................................28

Operation.........................................................................................................29-30

EngagingtheClutch for BinSweep .......................................................................31

FinalCleanout.......................................................................................................32

Shutdown ..............................................................................................................33

MaintainingtheAuger............................................................................................24

Troubleshooting................................................................................................35-36

Parts ...............................................................................................................37-49

Warranty....................................................................................... Inside Back Cover