Table of Contents

PNEG-1858 12" and 16" “X” Series Sweep 3

Contents

Chapter 1 Safety .....................................................................................................................................................4

Safety Guidelines .................................................................................................................................. 4

Safety Instructions ................................................................................................................................. 5

Operator Qualifications ......................................................................................................................... 9

Chapter 2 Safety Decals ......................................................................................................................................10

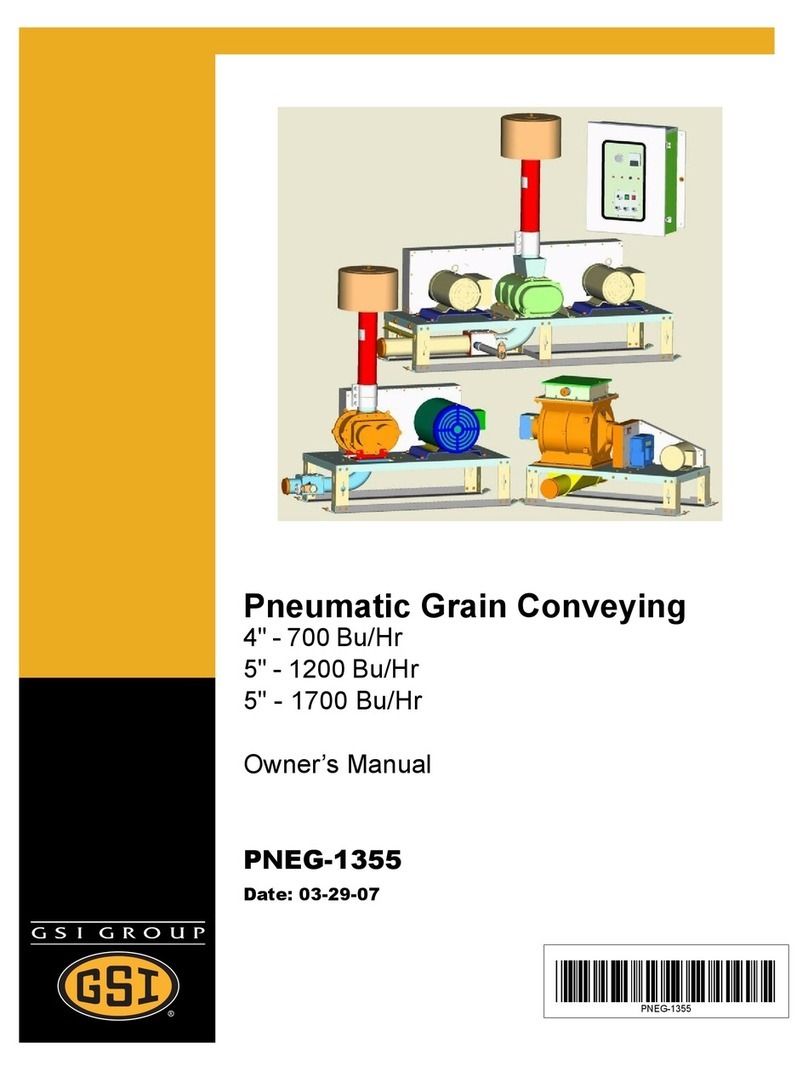

Chapter 3 Product Overview ...............................................................................................................................14

Sweep Criteria Recommendations ...................................................................................................... 14

Product Information ............................................................................................................................. 16

General Information ............................................................................................................................ 16

Capacities and Specifications ............................................................................................................. 18

Chapter 4 Start-Up ...............................................................................................................................................21

Perform Pre-Start Checks ................................................................................................................... 21

Start the Auger .................................................................................................................................... 21

Chapter 5 Operation ............................................................................................................................................22

Operating the Sweep Auger ................................................................................................................ 22

Operating in Manual Mode .................................................................................................................. 23

Operating in Auto Mode ...................................................................................................................... 27

Cleanout Mode .................................................................................................................................... 29

Warning Messages ............................................................................................................................. 31

Chapter 6 Shut Down ...........................................................................................................................................32

Normal Shut Down .............................................................................................................................. 32

Emergency Shut Down ....................................................................................................................... 32

Storage Preparation ............................................................................................................................ 32

Chapter 7 Maintenance ........................................................................................................................................33

Maintain the Auger .............................................................................................................................. 33

Lubrication ........................................................................................................................................... 34

Chapter 8 Control Panel Diagrams .....................................................................................................................39

Control Panel Schematic 380V and 480V ........................................................................................... 39

Control Panel Schematic 600V ........................................................................................................... 40

Chapter 9 Troubleshooting .................................................................................................................................41

FAQs ................................................................................................................................................... 42

Chapter 10 Parts List ...........................................................................................................................................49

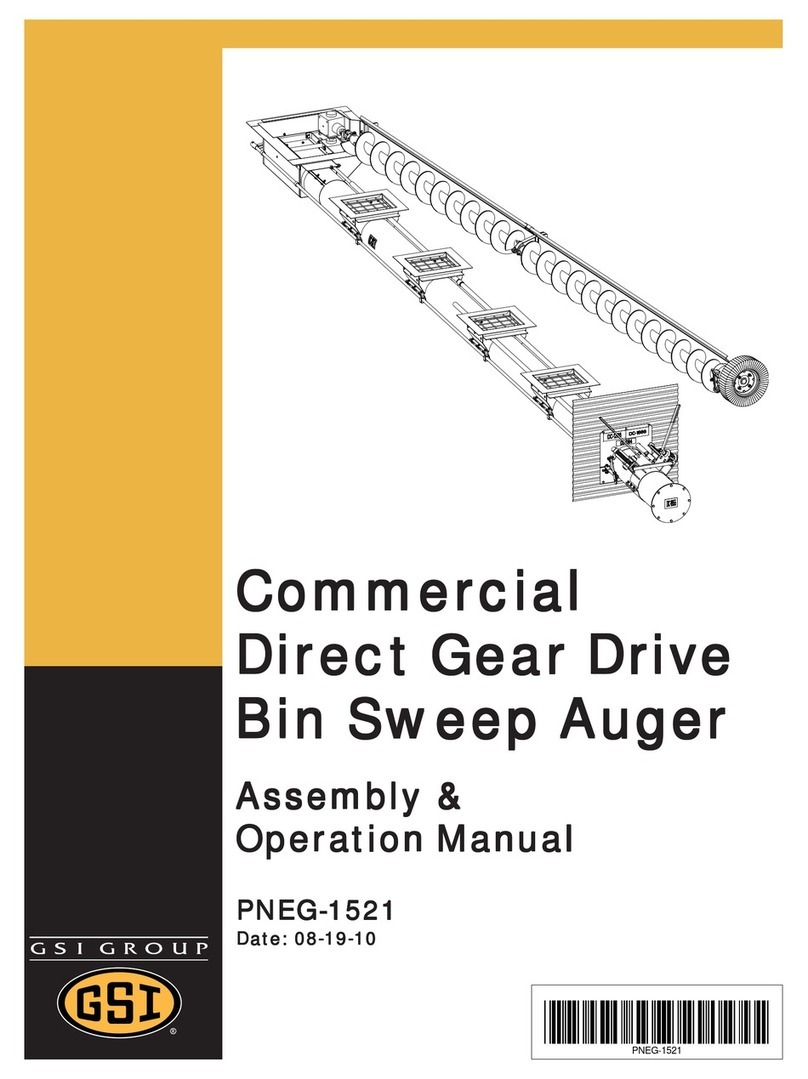

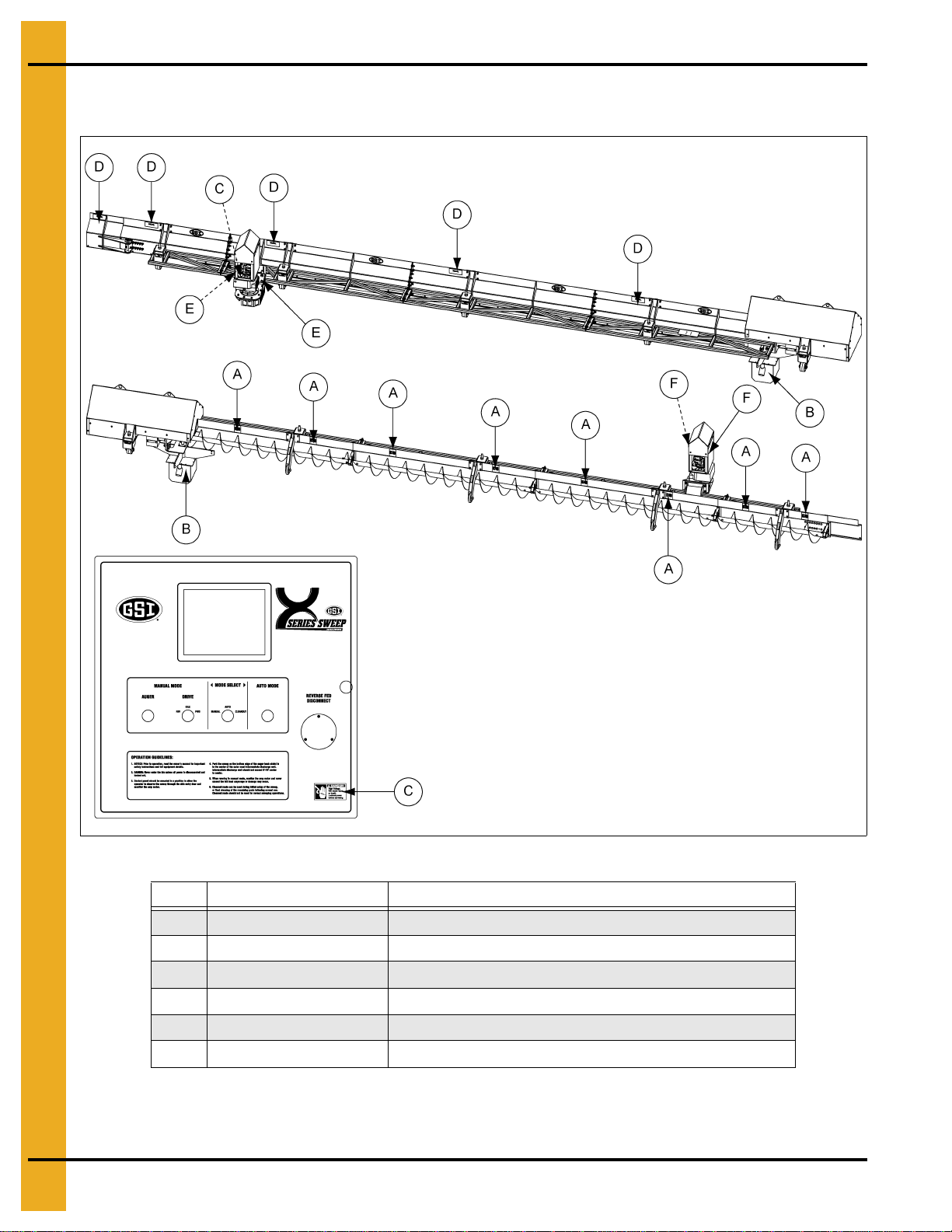

Main Auger Components ................................................................................................................... 50

Auger Drive Components .................................................................................................................. 54

Track Drive Components ................................................................................................................... 56

Flight Components ............................................................................................................................ 58

Wheel and Caster Components ........................................................................................................ 62

12" and 16'' Plow Components .......................................................................................................... 64

Center Pivot and Collector Ring Components (Prior to 2013) ........................................................... 66

Center Pivot and Collector Ring Components (Current) ................................................................... 68

Electrical Connection Components ................................................................................................... 70

Control Panel Components ............................................................................................................... 71

Control Panel Assembly - 380V 3 Phase .......................................................................................... 72

Control Panel Assembly - 480V 3 Phase .......................................................................................... 74

Control Panel Assembly - 600V 3 Phase .......................................................................................... 76

Components ...................................................................................................................................... 78

Chapter 11 Warranty ............................................................................................................................................79