-5-

CONTENTS

Chapter 1 Quick Start..................................................................................8

1.1 Introduction...................................................................................................................................................8

1.2 InitialChecking..............................................................................................................................................8

1.3 EnvironmentChecking...................................................................................................................................8

1.4 InstallationChecking......................................................................................................................................8

Chapter 2 Installation Guidance...................................................................9

2.1 Introduction...................................................................................................................................................9

2.2.2 BatteryRoom................................................................................................................................10

2.2.3 Storing..........................................................................................................................................10

2.3 Disassembly, InitialCheckingandPositioning..............................................................................................10

2.3.1 SystemPacking.............................................................................................................................10

2.3.1.1 Remove the ups fromthe pallet.................................................................................................11

Fig 2-1 UPS Packing Diagram...................................................................11

2.3.2 UPS Composition..........................................................................................................................12

2.3.3 OperationSpace............................................................................................................................12

2.3.4 FrontandBack Access...................................................................................................................12

2.3.5 FinalPositioning...........................................................................................................................12

2.3.6 Cable Entry...................................................................................................................................12

2.4 Protective Devices........................................................................................................................................12

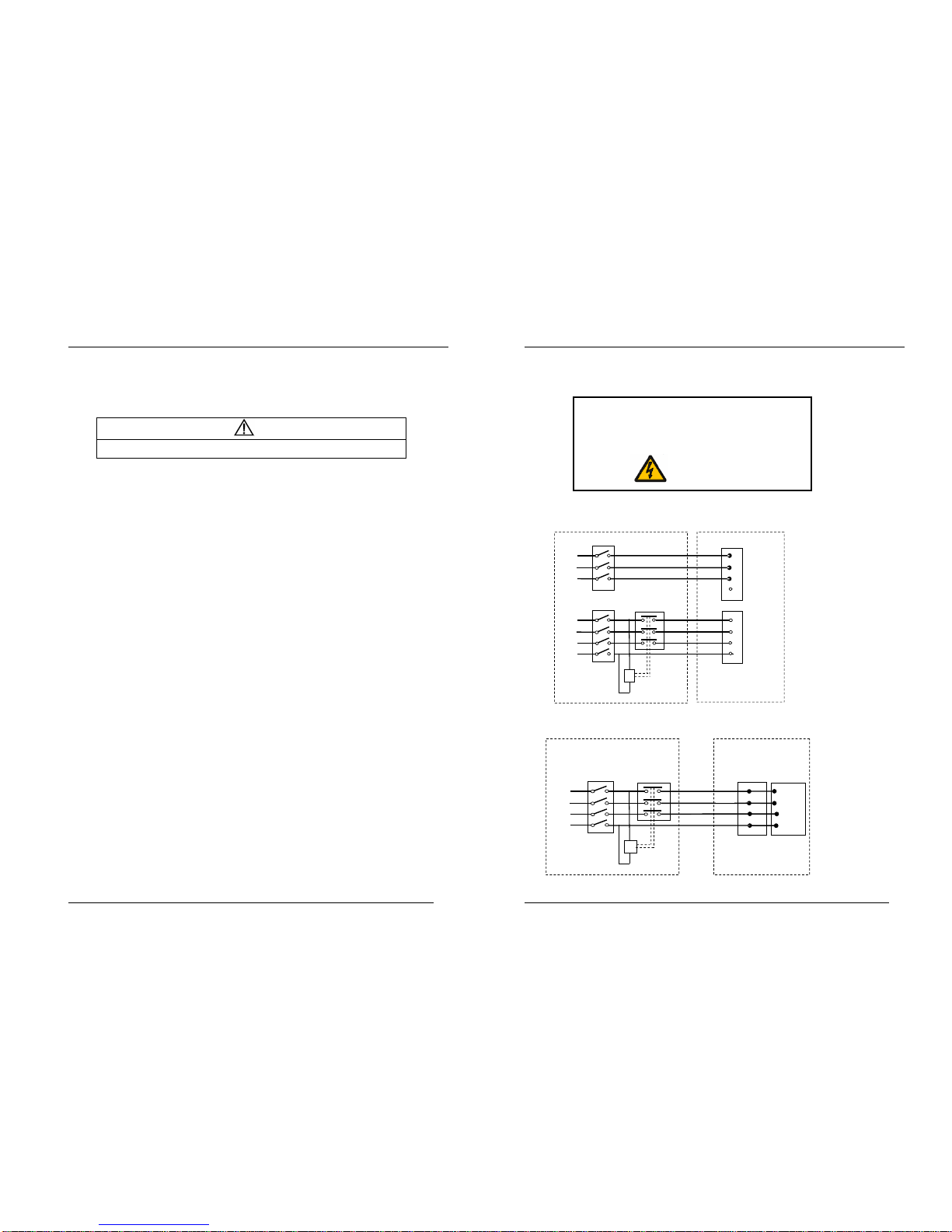

2.4.1.1 Rectifier andBypass InputSupplyofthe UPS.............................................................................13

2.4.1.2 Beakfeed Protection.................................................................................................................14

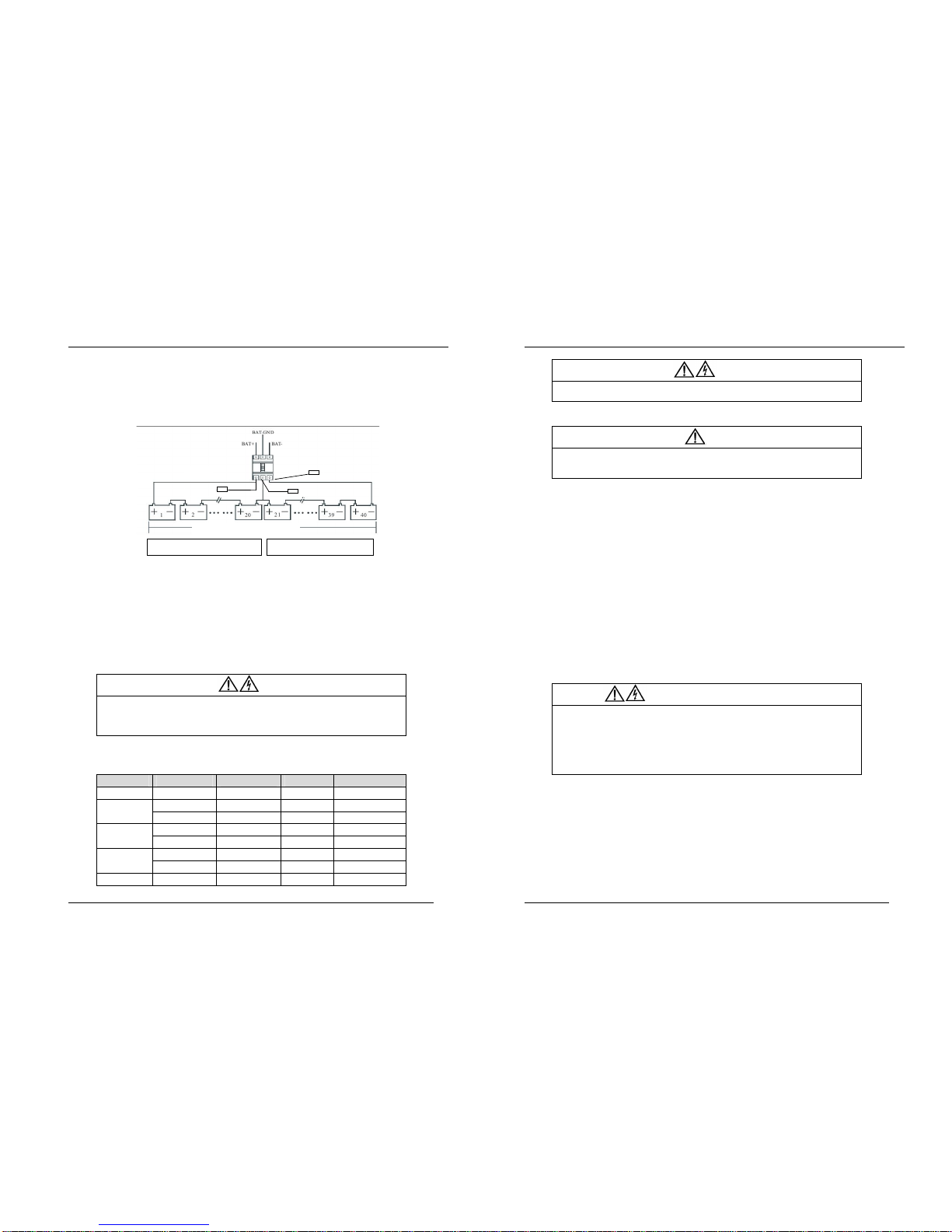

2.4.3 Battery..........................................................................................................................................15

2.4.3 UPS Output...................................................................................................................................15

2.5 Power Cables...............................................................................................................................................15

2.5.1 Maximumstablestate currentand configurationofminimumcable system.....................................15

2.5.2 Cable Connection..........................................................................................................................16

2.5.3 Connectionfor Battery...................................................................................................................17

2.6 ControlandCommunicationCabling............................................................................................................20

2.6.1 DryContactInterface of BatteryandEnvironmentalTemperatureDetection(Optional)...................20

2.6.2 RemoteEPOInput Port(Optional).................................................................................................21

2.6.3 Generator Input DryContact(Optional).........................................................................................22

2.6.4 BCBInterface (Optional)...............................................................................................................22

2.6.5 BatteryWarningOutputDryContact Interface (Optional)...............................................................23

2.6.6 GeneralWarningOutputDryContactInterface (Optional)..............................................................23

2.6.7 Mains FailureWarning OutputDryContact(Optional)...................................................................24

2.6.8 RS232-RS485PortandSNMP Card Port.......................................................................................24

2.7 InstallationDiagram..................................................................................................................................25

Chapter 3 Operations................................................................................27

3.1 Introduction.................................................................................................................................................27

3.1.1 Principle........................................................................................................................................27

3.1.2 Bypass..........................................................................................................................................28

3.1.3 BatteryTemperatureCompensation...............................................................................................28

3.2 OperationMode...........................................................................................................................................28

3.2.1 NormalMode................................................................................................................................29

3.2.2 BatteryMode................................................................................................................................29

-6-

NS3000 Series User Manualrev.01

3.2.3 Auto-RestartMode........................................................................................................................29

3.2.4 Bypass Mode.................................................................................................................................29

3.2.5 Maintenance Mode........................................................................................................................29

3.2.6 ECOMode....................................................................................................................................29

3.2.7 FrequencyConverters Mode..........................................................................................................29

3.2.8 Parallelconnectionredundancymode.............................................................................................30

3.3 BatteryManagement....................................................................................................................................30

3.3.1 NormalFunction...........................................................................................................................30

3.3.2 Advanced Functions (BatterySelf-checking andMaintenance).......................................................30

3.4 BatteryProtection........................................................................................................................................30

Chapter 4 Installation of Parallel Operation System....................................31

Chapter 5 Operating Procedures................................................................33

5.1 Power Switches............................................................................................................................................33

5.2 UPS Start-up................................................................................................................................................33

5.2.1 NormalModeStart........................................................................................................................33

5.2.2 BatteryModuleStart Only Applicablefor theUPS withBatteryCold StartElements)..............35

5.3 Procedure for Switching betweenOperationModes.......................................................................................35

5.3.1 Procedure for Switching the UPS intoBatteryfromNormalMode..................................................35

5.3.2 Procedure for Switching the UPS intoBypass fromNormalMode..................................................35

5.3.3 Procedure for Switching the UPS intoNormalfromBypass Mode..................................................36

5.3.4 Procedure for Switching the UPS intoaMaintenance Bypass fromNormalMode...........................36

5.3.5 Procedure for Switching the UPS intoNormalfroma Maintenance Bypass Mode...........................36

5.4 Procedure for CompletelyPowering downa UPS..........................................................................................36

5.5 EPOProcedure.............................................................................................................................................37

5.6 LanguageSelection......................................................................................................................................37

5.7 ControlPassword.........................................................................................................................................37

Chapter 6 Operator Control and Display Panel...........................................38

6.1 Introduction.................................................................................................................................................38

6.1.1 LEDIndicator...............................................................................................................................39

6.1.2 Audible Alarm(buzzer).................................................................................................................39

6.1.3 FunctionalKeys............................................................................................................................40

6.2 LCDDisplayType.......................................................................................................................................40

6.2.1 DefaultDisplay.............................................................................................................................40

6.2.2 DataDisplay..................................................................................................................................40

6.2.3 Setting Display..............................................................................................................................41

6.2.4 FunctionDisplay...........................................................................................................................41

6.2.5 StateDisplay.................................................................................................................................41

6.2.6 ConfirmDisplay............................................................................................................................42

6.2.7 HistoryRecordDisplay..................................................................................................................42

6.3 DetailedDescriptionofMenu Items..............................................................................................................43

6.4 AlarmList...................................................................................................................................................44

Chapter 7 Maintenance..............................................................................45

7.1 Instructionof Maintenance Operation...........................................................................................................45

7.1.1 Precautions....................................................................................................................................45

7.1.2 Instructionto Bypass Module.........................................................................................................45

Chapter 8 Product Specification.................................................................46

8.1 Applicable Standards....................................................................................................................................46