www.gtm-gmbh.com

Series KTN-ZD (eng.) 16/09/2022 Page 3

#PrecisionWins

Table of contents

1. Product description.............................................................................. 4

1.1 Designated use........................................................................... 4

1.2 Exempted use............................................................................. 4

2. Safety instructions................................................................................ 5

3. Storage and transport instructions ..................................................... 9

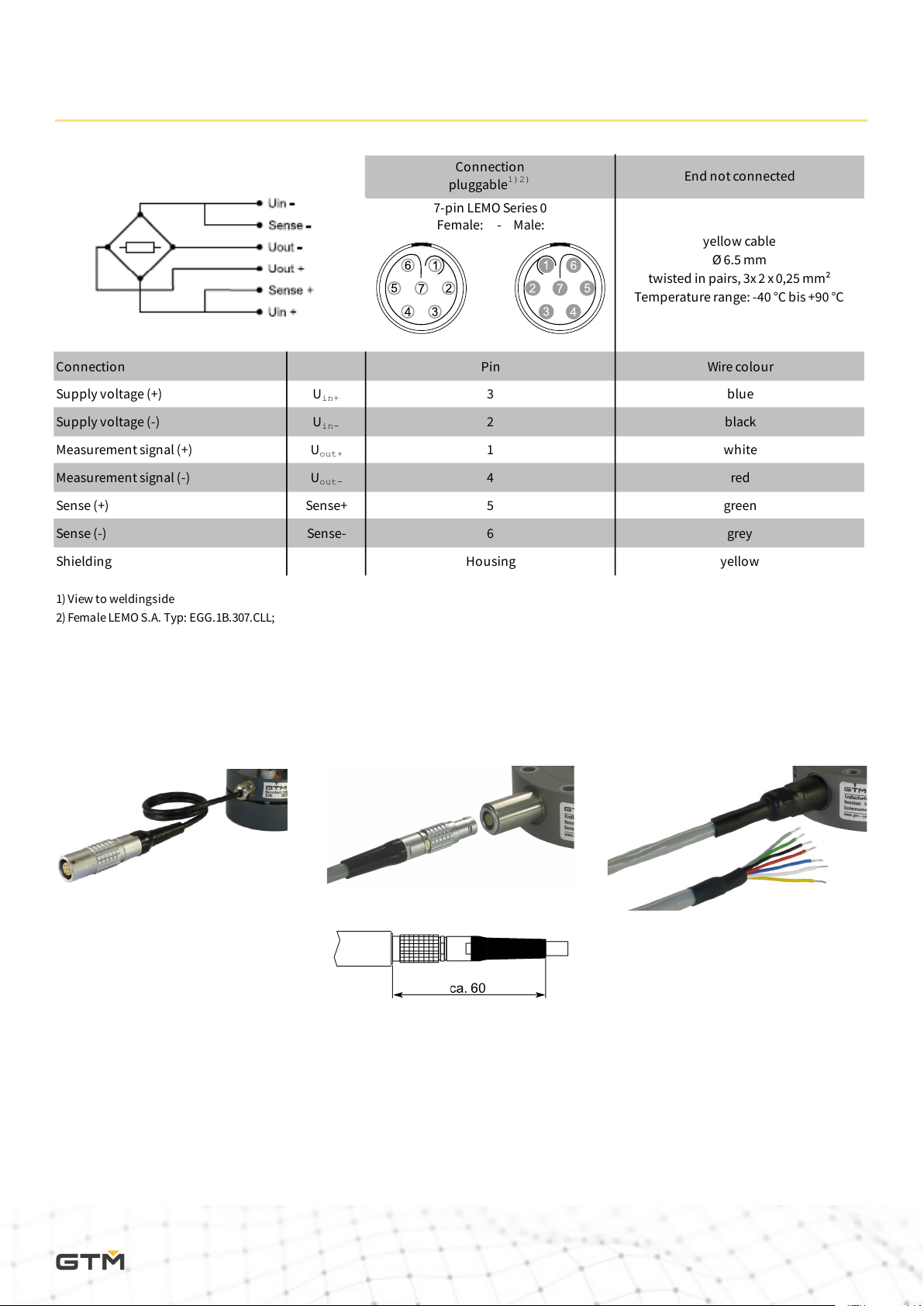

4. Cable connection ............................................................................... 10

5. Double Bridge ..................................................................................... 11

6. Bending Moment Measuring Circuits ................................................ 12

7. Temperature Measurement ............................................................... 13

8. Application instructions .................................................................... 14

8.1 Assembly instruction............................................................... 14

9. Mating dimensions ............................................................................. 15

9.1 Construction size 5 N - 100 N................................................... 15

9.2 Construction size 200 N - 2500 N............................................. 16

9.3 Dimensions of construction size 5 N - 2500 N ........................ 17

9.4 Construction size 5 kN - 100 kN............................................... 18

9.5 Construction size 200 kN - 500 kN.......................................... 19

9.6 Construction size 1000 kN ...................................................... 20

9.7 Dimensions of construction size 5 kN - 1000 kN .................... 21

10. Technical Data..................................................................................... 22

10.1 Class 00 | Construction size 5 N - 500 N................................... 22

10.2 Class 00 | Construction size 1 kN - 1000 kN............................. 23

10.3 Class 0,5 | Construction size 5 N - 500 N.................................. 24

10.4 Class 0,5 | Construction size 1 kN - 1000 kN............................ 25

11. Technical support ............................................................................... 26

12. Declaration of incorporation.............................................................. 27