OPERATING INSTR CTIONS

10

EXCAVATION PROCEDURE

•For most excavations the best performance is achieved by holding the A R-SPADE

nozzle at approximately a 45 degree angle from horizontal and about 1 inch away

from the surface to be excavated.

•Depending on the soil type, the A R-SPADE should be directed above the surface

to be excavated at a rate of approximately 1 to 2 feet per second

(0.3 to 0.6 meters per second).

•Except in very hard and compacted clays, dwelling on the same spot tends to reduce

the rate at which material is excavated and can increase the amount of material

blown away from the excavation site.

•Watering the work area ahead of time can often be helpful. Watering reduces

airborne dust if the soil is extremely dry. t also reduces the soil strength making

digging easier.

•For small diameter holes, position the A R-SPADE barrel perpendicular to the ground

with the nozzle close to the surface. Depress the trigger, and slowly thrust the tool into

the soil. When resistance is met, slowly withdraw the A R-SPADE and then reinsert.

This procedure allows loose soil at the bottom of the hole to exit upwards. Reinsert

the nozzle and repeat the above procedure until the desired depth of hole is reached.

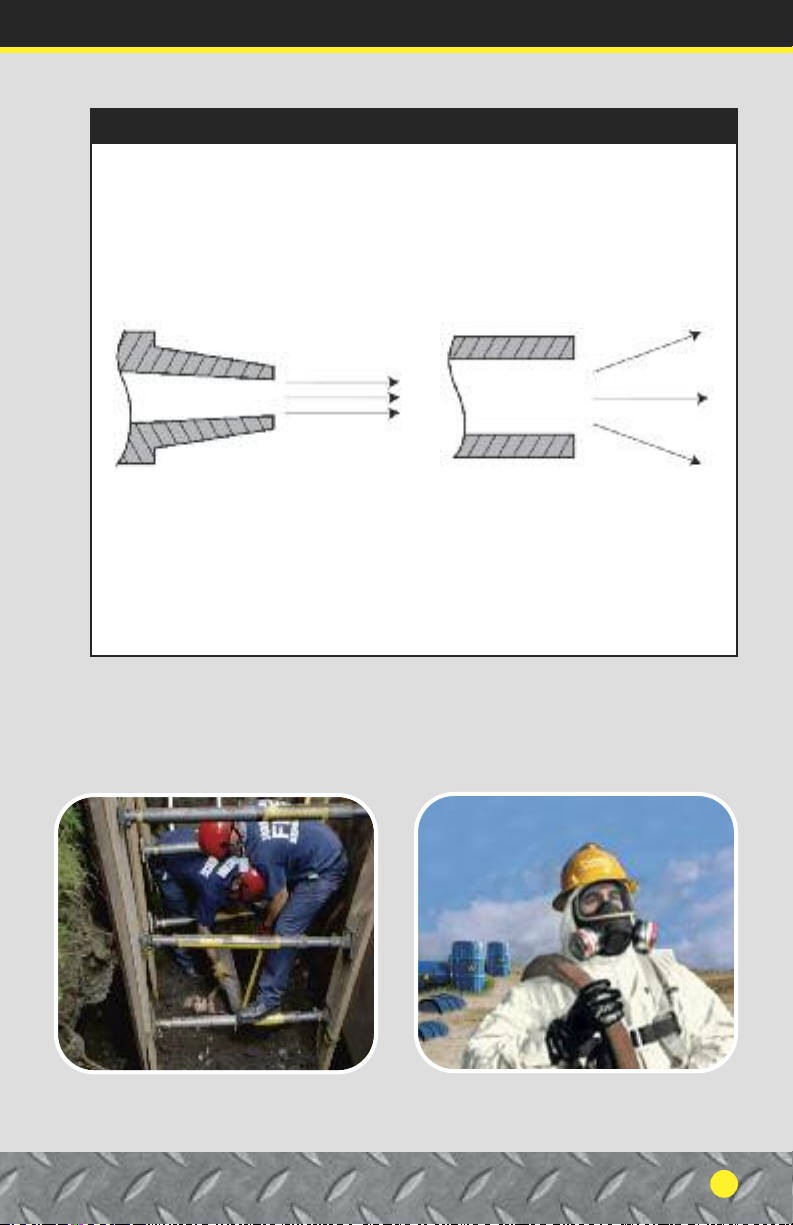

•When boring a small diameter hole, or when plunging the A R-SPADE into loose soil,

the tendency to expose the operator to blown back material is increased. The ad-

justable dirt shield should be positioned close to the ground to deflect airborne

material away from the operator.

•For large diameter holes, position the A R-SPADE at an angle between 30° and 45°

from the horizontal. Depress the trigger and move the A R-SPADE back and forth

across the footprint of the excavation to loosen the soil to a depth of several inches.

Each layer of loose soil should then be removed with a shovel, backhoe, or vacuum.

Repeat the procedure until the desired depth is reached.

•For shallow, wide excavations, position the A R-SPADE at an angle between 30° and

45° from the horizontal. Depress the trigger, move the nozzle from side to side the

desired width, and blow the loosened soil ahead of the nozzle. Continue until the

excavation is completed to the required length.