Page 2

GUARDIAN RCC-12 Issue vE-1.2A 03/08/00

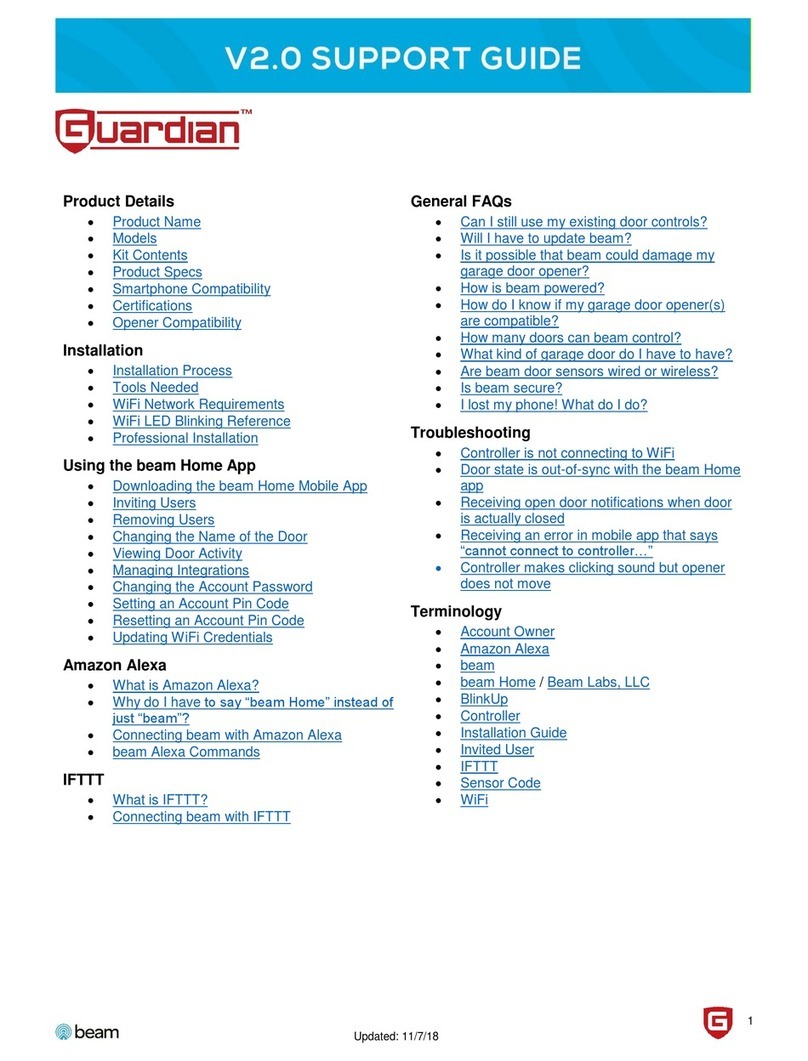

CONTENTS

GUARDIAN RCC-12 ...............................................................................1

RECIPROCATING COMPRESSOR CONTROLLER................................................. 1

GETTING STARTED.................................................................................................. 3

SKD.9 KEYSWITCH DISPLAY OPERATION.................................................................................... 3

BUTTON OPERATION SHORTHAND................................................................................................ 4

HARDWARE CONFIGURATION CHECKS ........................................................................................ 4

CONFIGURE UNIT MODEL, SYSTEM No & ADDRESS...................................................................5

5Unit Enter Passcode PP05 for normal changes............................................................................. 5

Select Model ....................................................................................................................................5

Select System No and Address .......................................................................................................5

RS485 Communications..................................................................................................................5

UNIT MODELS........................................................................................................... 6

Available unit models (RCC-12)...................................................................................... 6

GENERAL SPECIFICATION ............................................................................................. 6

RCC-12 ‘6PAC’ and ‘8PAC’ Input/Output Signals........................................................... 6

RCC.12 6PAC................................................................................................................... 7

RCC-12 Termination Wiring - ‘6PAC’ model selection ................................................ 7

RCC.12 8PAC.................................................................................................................... 8

RCC-12 Termination Wiring - ‘8PAC’ model selection ................................................ 8

OPERATION............................................................................................................... 9

DISPLAY INDICATIONS.................................................................................................. 10

Compressor Displays.....................................................................................................................10

Default Displays.............................................................................................................................11

TRIPS AND ALARMS...................................................................................................... 11

COMPRESSOR SAFETY TRIPS ................................................................................. 11

Analogue Trips.......................................................................................................... 11

ALARMS....................................................................................................................... 12

Analogue Alarms....................................................................................................... 12

Digital Alarms............................................................................................................ 12

PC-FAIL ALARM....................................................................................................... 12

MODE CHANGE Compressors .................................................................................... 12

Pack Capacity Manual .............................................................................................. 13

GLOBAL RS485 COMMANDS..................................................................................... 13

USEFUL BUTTON SEQUENCES ................................................................................ 14

Reset ALARM or TRIP.................................................................................................. 14

Change suction control setpoint and differential............................................................................14

Check Unit Model...........................................................................................................................14

Select Stub, Case No and Address................................................................................................14

SETUP OPERATION............................................................................15

Setup Functions (Normal) passcode 05....................................................................... 16

PP05 Menu...................................................................................................................... 16

Compressor Settings..................................................................................................... 17

PP11 Menu - SETTINGS LEVEL 2.................................................................................. 21

COMPRESSORS......................................................................................................... 21

COMMUNICATIONS.............................................................................22

CONSULTANT DISPLAYS.............................................................................................. 23

SETUP / COMMISSIONING PARAMETERS........................................24

PP05 Normal Menu Compressor Settings.....................................................................................24

PP11 Menu - Settings Level 2........................................................................................................26

INDEX...................................................................................................27