3

• When working on this equipment, remain alert

at all times. Never work on the equipment when

physically or mentally fatigued.

• Inspect the generator regularly, and contact the

nearest Authorized Service Dealer immediately for

parts needing repair or replacement.

• Before performing any maintenance on the genera-

tor, disconnect its battery cables to prevent acci-

dental startup. First, disconnect the cable from the

battery post, indicated by a NEGATIVE, NEG, or

(–). Reconnect this cable last.

• Never use the generator, or any of its parts, as a

step. Stepping on the unit can stress and break

parts, resulting in dangerous operating conditions

due to leaking exhaust gases, fuel leakage, oil leak-

age, etc.

• Never insert any tool or other object through open-

ings in the generator interior, even if the unit is not

running. Serious injury or damage to the equip-

ment could be done.

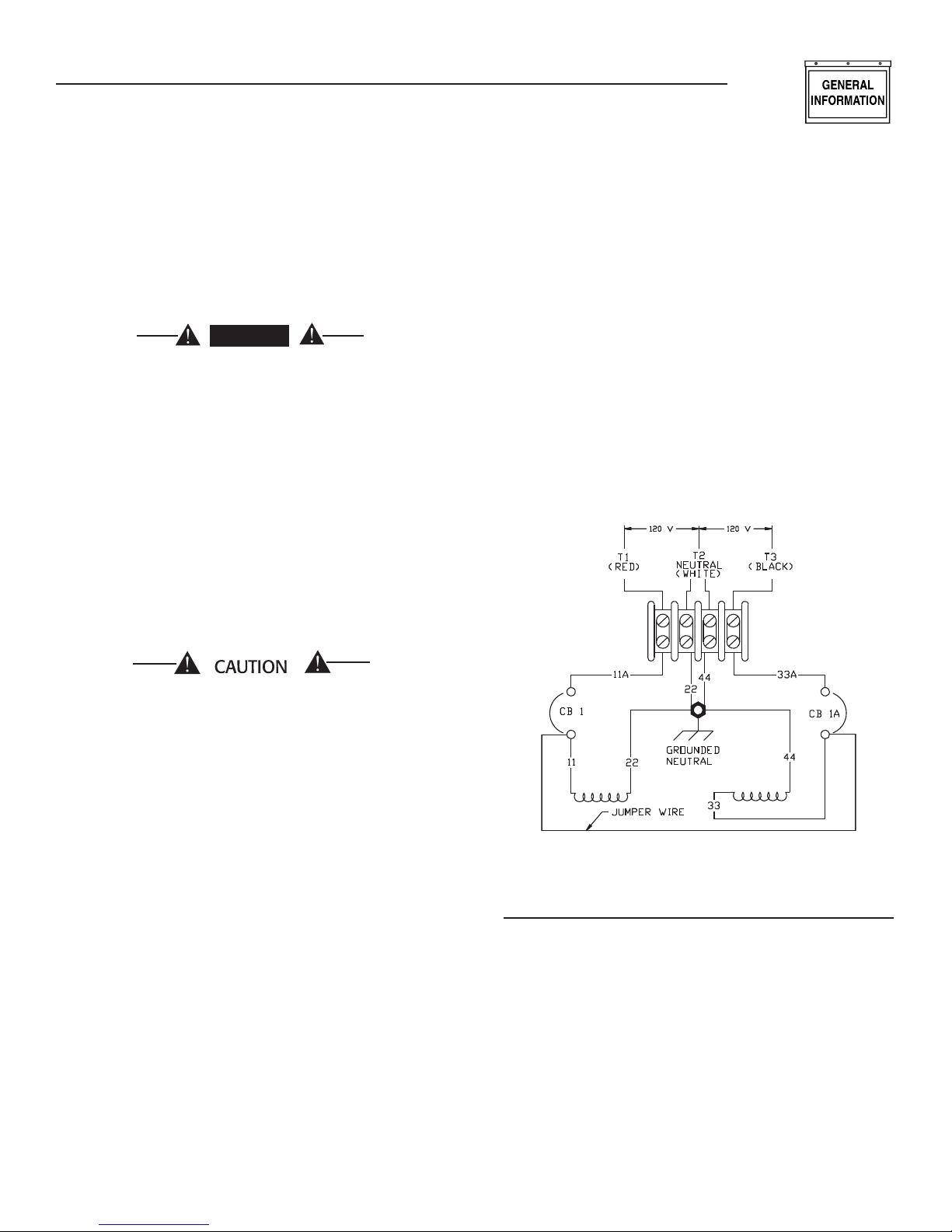

ELECTRICAL HAZARDS

• The generator covered by this manual produces

dangerous electrical voltages and can cause fatal

electrical shock. Avoid contact with bare wires,

terminals, connections, etc., while the unit is run-

ning. Before operating the generator, ensure all

appropriate covers, guards, and barriers are in

place . If work must be done around an operating

unit, stand on an insulated, dry surface to reduce

shock hazard.

• Do not handle any kind of electrical device while

standing in water, while barefoot, or while hands or

feet are wet. DANGEROUS ELECTRICAL SHOCK

MAY RESULT.

• During installation onto the vehicle, have the

generator properly grounded (bonded), either by

solid mounting to the vehicle frame or chassis,

or by means of an approved bonding conductor.

DO NOT disconnect the bonding conductor, if so

equipped. DO NOT reconnect the bonding conduc-

tor to any generator part that might be removed or

disassembled during routine maintenance. If the

grounding conductor must be replaced, use only a

flexible conductor that is of No. 8 American Wire

Gauge (AWG) copper wire minimum.

• In case of an accident caused by electric shock,

immediately shut down the source of electrical

power. If this is not possible, attempt to free the

victim from the live conductor. AVOID DIRECT

CONTACT WITH THE VICTIM. Use a nonconduct-

ing implement, such as, a dry rope or board, to

free the victim from the live conductor. If the victim

is unconscious, apply first aid and get immediate

medical help.

• Never wear jewelry when working on this equip-

ment. Jewelry can conduct electricity, resulting in

electric shock, or may get caught in moving com-

ponents, causing, injury.

FIRE HAZARDS

• For fire safety, the generator must be installed

and maintained properly. Installation must always

comply with NFPA 70 (latest edition), “National

Electrical Code”, Article 551, and NFPA 1192 (lat-

est edition), “Standard for Recreational Vehicles”,

along with all applicable codes, standards, laws,

and regulations. Adhere strictly to local, state, and

federal electrical and building codes. Comply with

regulations the Occupational Safety and Health

Administration (OSHA) has established. Also,

ensure that the generator is installed in accordance

with the manufacturer’s instructions and recom-

mendations. After proper installation, do nothing

that might alter the installation and render the unit

in noncompliance with the aforementioned codes,

standards, laws, and regulations.

• Keep a fire extinguisher in the vehicle at all times.

Extinguishers rated “ABC” by the National Fire

Protection Association are appropriate for use on

the recreational vehicle generator electrical sys-

tem. Keep the extinguisher properly charged and

be familiar with its use. If there are any questions

pertaining to fire extinguishers, consult the local

fire department.

EXPLOSION HAZARDS

• Do not smoke around the generator. Wipe off

any fuel or oil spills immediately. Ensure that no

combustible material is left in the generator com-

partment, or on or near the generator, as FIRE or

EXPLOSION may result. Keep the area surround-

ing the generator clean and free of debris.

• All fuel types are potentially FLAMMABLE and/or

EXPLOSIVE and should be handled with care.

Comply with all laws regulating the storage and

handling of fuels. Inspect the unit’s fuel system fre-

quently and correct any leaks immediately. Before

placing this equipment into service, the fuel supply

lines must be properly installed, purged, and leak-

tested according to applicable fuel-gas codes.

Safety Rules

Recreational Vehicle Generator