List of Contents

ARTICLE Page

1. Technical Data.............................................................................................................................................................

2. General Safety Precautions.........................................................................................................................................

3. Other General Safety Precautions...............................................................................................................................

4. Drills-Specific Safety Precautions................................................................................................................................

5. Electrical Part Information............................................................................................................................................

6. Meet Your Drill.............................................................................................................................................................

7. Assembling..................................................................................................................................................................

8. Adjustment..................................................................................................................................................................

9. Operation....................................................................................................................................................................

10. Maintenance ...............................................................................................................................................................13

11.

Drilling Specifications Table

....................................................................................................................................14

12. Machine Exploded View Drawing................................................................................................................................15

13. List of Spare Parts for GTB 13...................................................................................................................................16

14. List of Spare Parts GTB 16. GTB 20. GSB 20. GSB 25 R+L. GSB 32 R+L..............................................................17

15. Pack Sheet GTB 13....................................................................................................................................................18

16. Pack Sheet GTB 16. GTB 20. GSB 20. GSB 25 R+L. GSB 32 R+L...........................................................................18

1. Technical Data

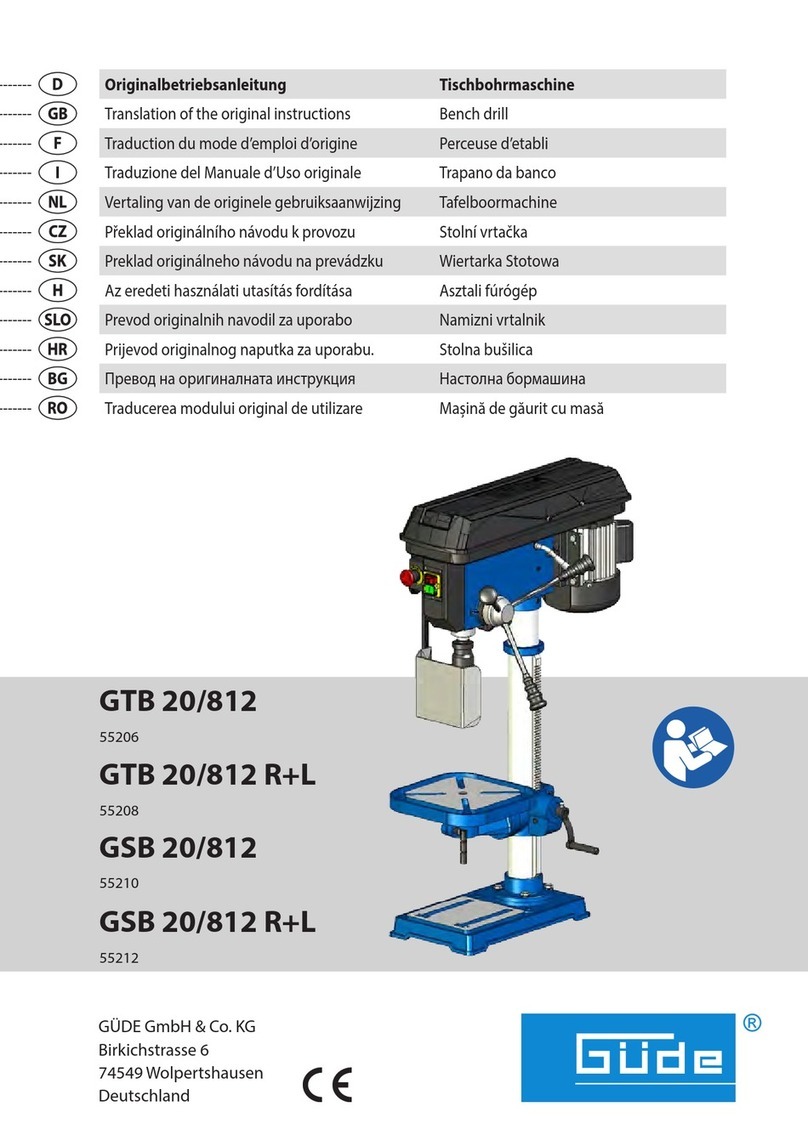

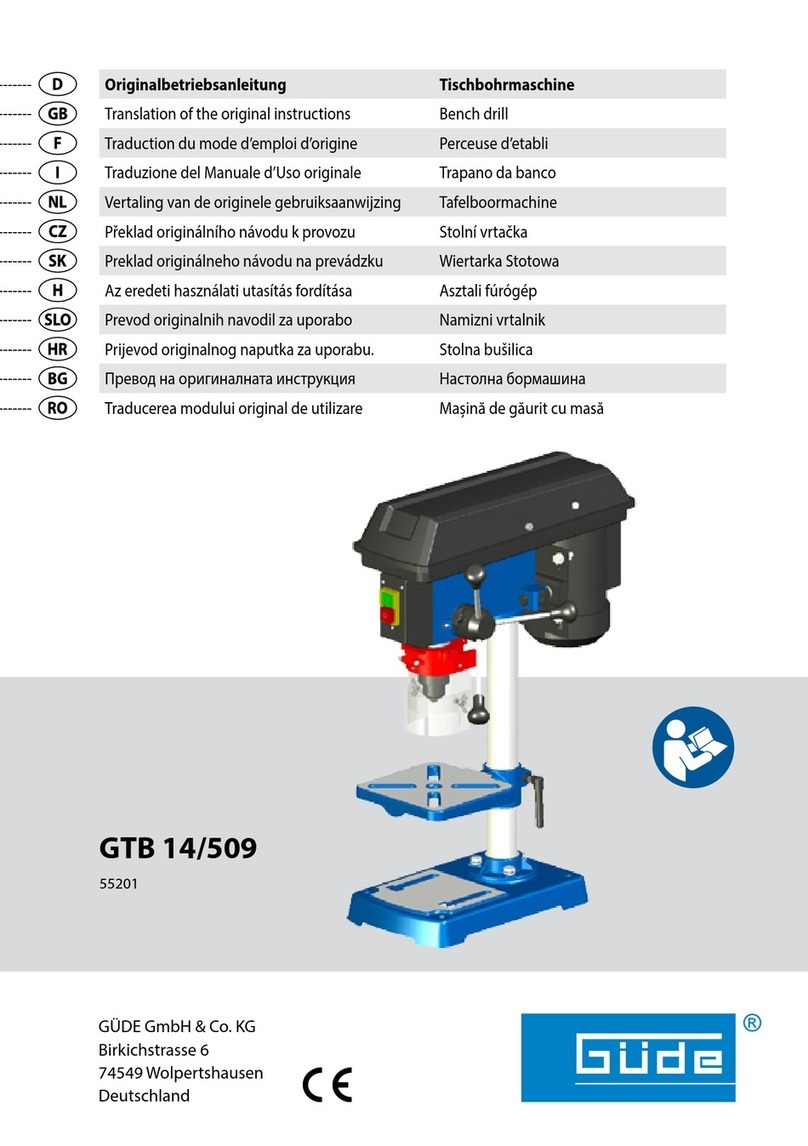

Model GTB 13 GTB 16/5 GTB 16/5 R+L GTB 20/12 GTB 20/12 R+L

Supply voltage:

230 V/50 Hz 230 V 400 V 230 V 230 V

Motor capacity:

180 W 600 W 600 W 800 W 800 W

Chuck:

13 mm 16 mm 16 mm 16 mm 16 mm

Quill stroke:

50 mm 60 mm 60 mm 80 mm 80 mm

Taper attachment:

MK 1/B16 MK 2 MK 2 MK 2 MK 2

Reach:

105 mm 126 mm 126 mm 178 mm 178 mm

Bench size:

164 x 164 mm 200 x 195 mm 200 x 195 mm 300 x 300 mm 300 x 300 mm

Base plate size:

295 x 185 mm 348 x 210 mm 348 x 210 mm 456 x 270 mm 456 x 270 mm

Total height:

580 mm 840 mm 840 mm 1065 mm 1065 mm

Quill speed:

500-2500 rpm. 5 dg 12 dg 12 dg 12 dg

460-2480 rpm 230-2470 rpm 180-2740 rpm 180-2740 rpm

Ordering No.: 55120 55190 55192 55193 55194

Model GSB 20/12 GSB 20/12 R+L GSB 25 R+L GSB 32 R+L

Supply voltage:

230 V 400 V 400 V 400 V

Motor capacity:

600 W 800 W 1100 W 1500 W

Chuck:

16 mm 16 mm 3-16 mm 3-16 mm

Taper attachment:

MK 2 MK 2 MK 3/B16 MK 4

Quill stroke:

80 mm 80 mm 120 mm 120 mm

Reach:

178 mm 178 mm 210 mm 255 mm

Bench size:

300 x 300 mm 300 x 300 mm 335 x 335 mm 423 x 475 mm

Base plate size:

456 x 270 mm 456 x 270 mm 520 x 305 mm 450 x 580 mm

Total height:

1610 mm 1610 mm 1670 mm 1720 mm

Quill speed:

12 dg 12 dg 16 dg 12 dg

180-2740 rpm 180-2740 rpm 160-3000 rpm 120-3480 rpm

Ordering No.: 55195 55197 55423 55435

2. Microswitch Safety Device

In the drill belt enclosure, a safety switch is fitted. The machine will not start when the enclosure cover

is opened or not properly closed.

Always check this microswitch functioning when you experience troubles at start-up. However, never

leave the machine on when handling this microswitch manually. That could result in serious injury.

!