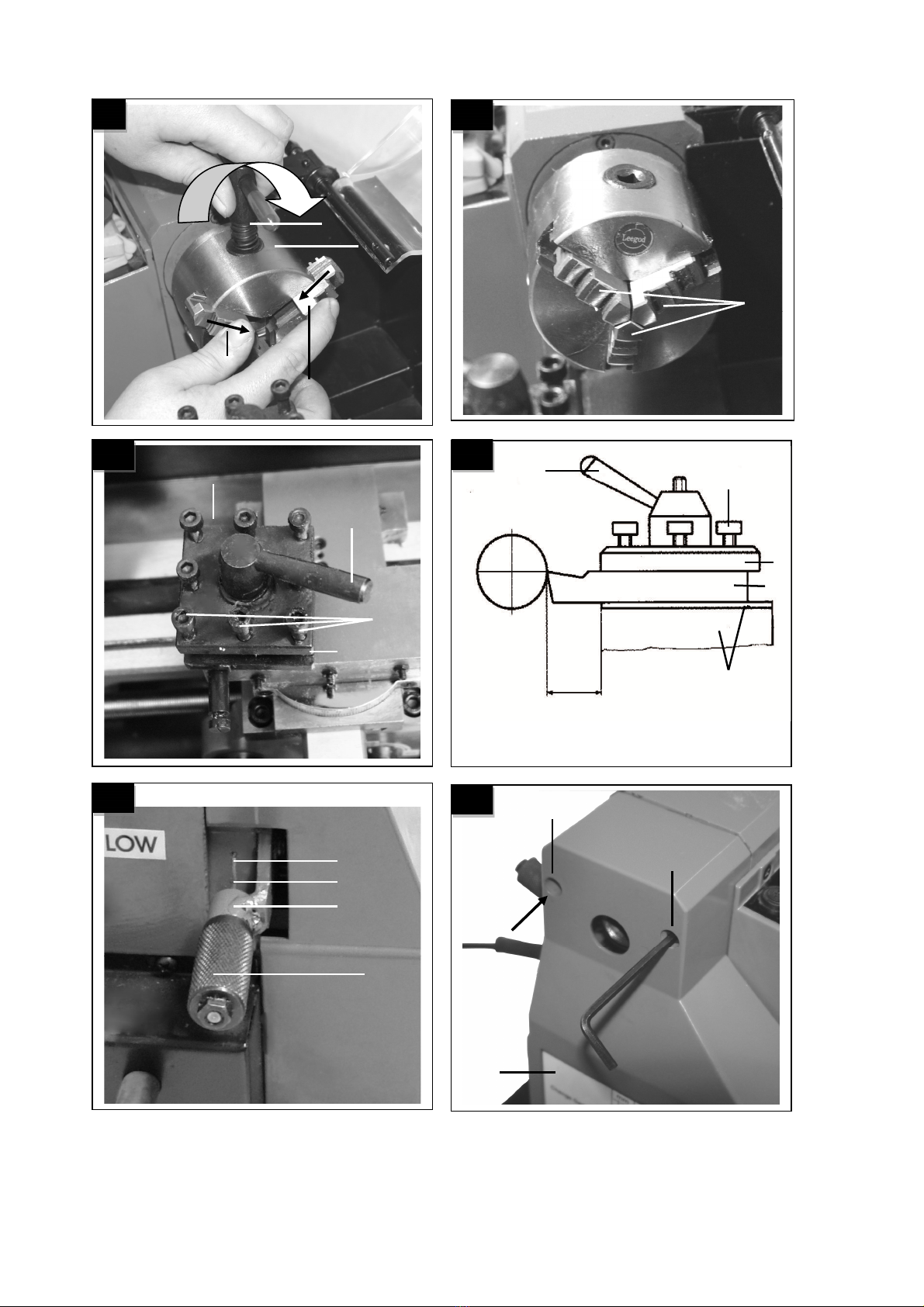

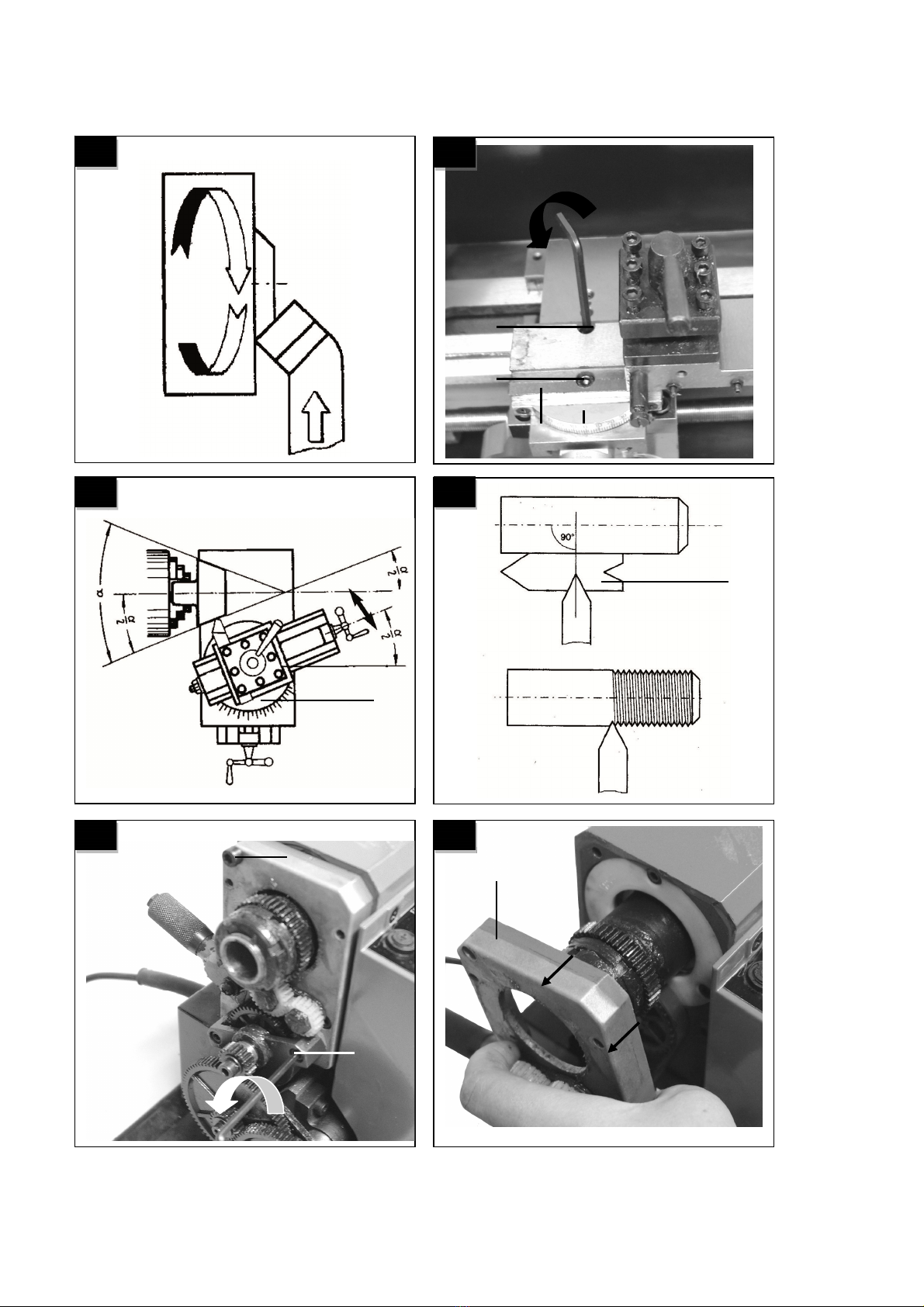

Geschwindigkeit nur im Stillstand umschalten!

Speed to be only switched when the machine is in idle state!

Commuter la vitesse uniquement en état stationnaire de la machine !

Cambiare la velocità solo con la macchina ferma!

Snelheid uitsluitend bij stilstand omschakelen!

Rychlost přepínat jen v klidovém stavu stroje!

Rýchlosť prepínať len v pokojovom stave stroja!

A sebesség kizárólag nyugalmi állapotú készülék esetében állítható!

Prędkość zmieniać tylko w stanie bezruchu!

¡Cambiar velocidad solo con el motor parado!

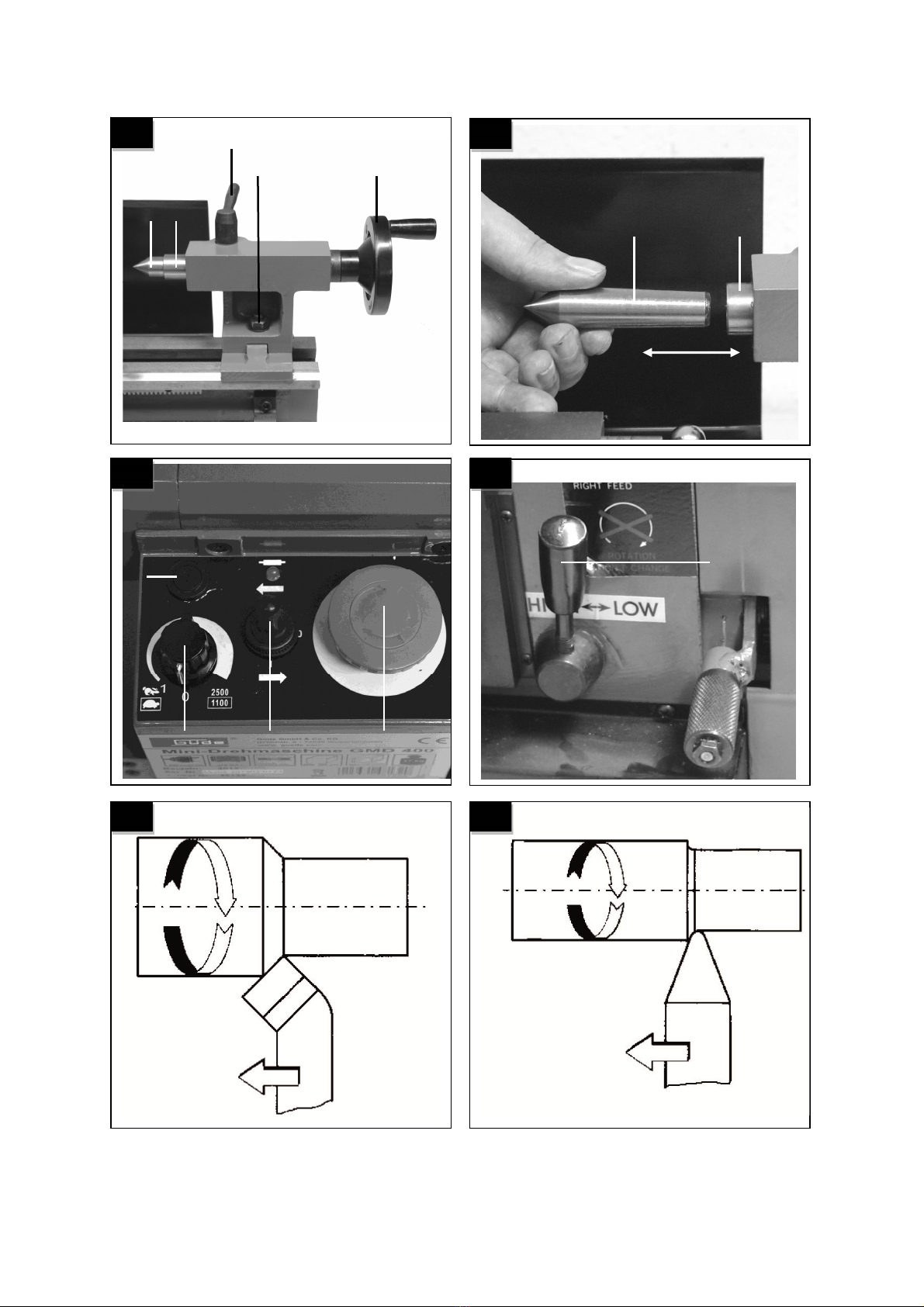

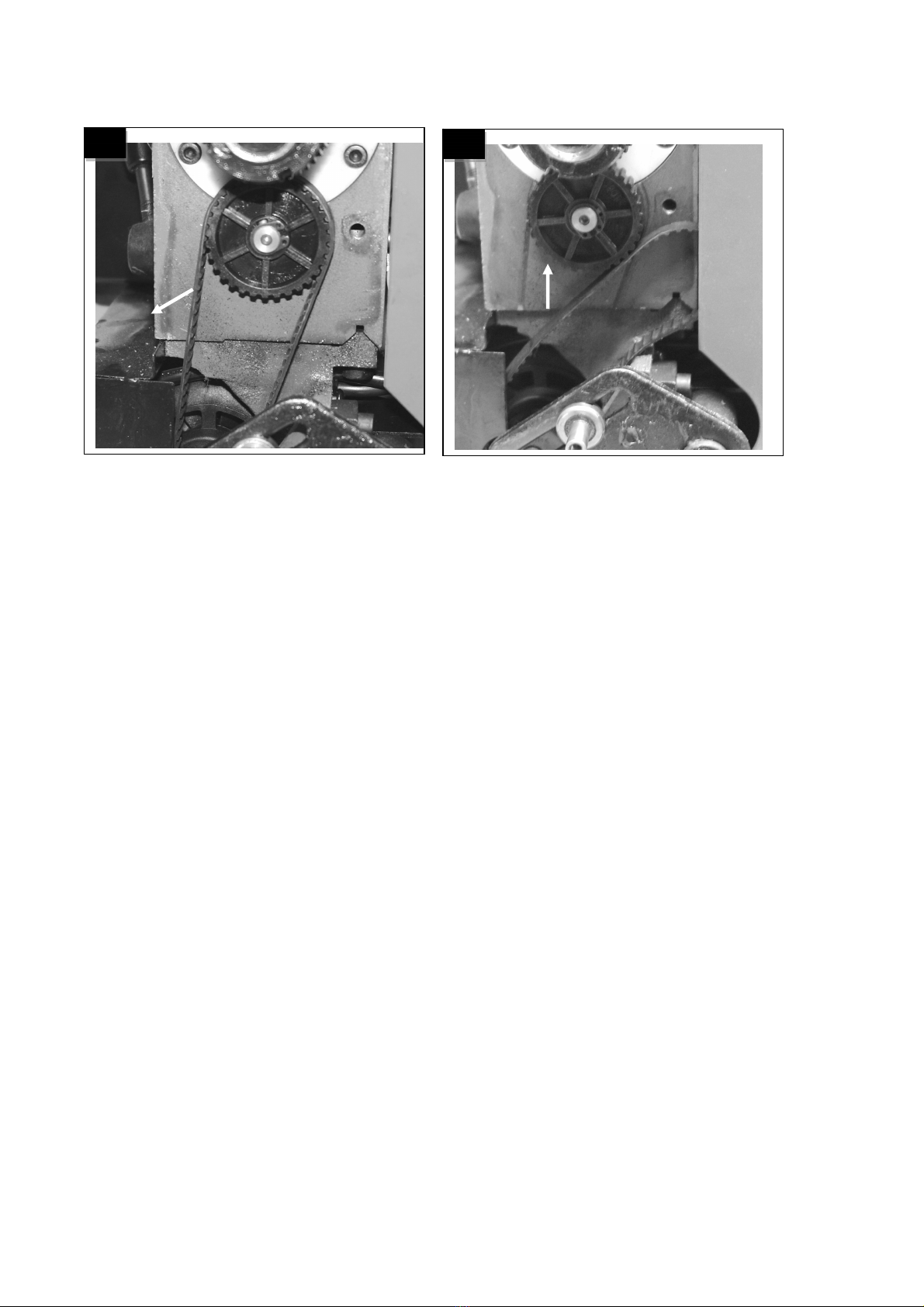

Drehrichtung nur im Stillstand umschalten!

Turning direction to be only switched when the machine is in idle state!

Commuter le sens des rotations seulement en état stationnaire de la machine!

Cambiare il senso di rotazione solo con la macchina ferma!

Draairichting uitsluitend bij stilstand omschakelen!

Směr otáčení přepínat jen v klidovém stavu stroje!

Rýchlosť prepínať len v pokojovom stave stroja!

Hitrost lahko preklopite, kadar stroj miruje!

Kierunek obrotow zmieniać tylko w stanie bezruchu!

¡Cambiar el sentido de giro solo con la máquina parada!

DE

EN

FR

IT

NL

CZ

SK

HU

PL

ES

DE

EN

FR

IT

NL

CZ

SK

HU

PL

ES