Date/producer signature: 01.01.2010

Signed by: Mr Arnold, Managing Director

Technical Documentation: J. Bürkle; FBL, QS

Appropriate EU Directives:

2006/42 EG

Harmonised standards used:

EN 14492-1:2006

Guarantee

The guarantee solely covers inadequacies caused by material

defect or manufacturing defect.

Original payment voucher with the sales date needs to be

submitted for any claim in the guarantee period.

The guarantee does not cover any unauthorised use such as

appliance overloading, use of violence, damage as a result of

any unauthorised interference or caused by foreign items.

Failing to follow the operating and assembly instructions and

common wear are also not included in the guarantee.

Use in Compliance with Determination

This tool is determined for lifting loads of 1,000 kg maximum.

Any use of it is subject to reading and understanding the

provisions of this manual.

The tool shall not be used for lifting/transporting animals.

The manufacturer shall not be held liable for any damages if

the generally valid regulations and provisions contained

herein are not observed.

General Safety Instructions

Before you start working with the appliance please read

carefully the following safety regulations and Operating

Instructions. If any other person is to handle the appliance

provide him/her with the Operating Instructions. Keep the

Operating Instructions for future reference!

Package: The appliance has been put in a package to

prevent any damage during transport. Packages are raw

materials so they can be reused or recycled.

Please read carefully the Operating Instructions and follow

them. Use these Operating Instructions to get acquainted

with the appliance, its corresponding use and safety

instructions. Keep the Instructions for future reference.

•Before getting down to work, make sure that all the

screwed joints are tightened as appropriate.

•The load of the unit shall not exceed the permissible

load shown in the technical data.

•Always start lifting at the lowest position allowed by the

piece worked.

•Mind the unit stability.

•Avoid any quiver of the load as that may result in the unit

instability.

•The unit should be always used on a firm, flat and

smooth floor of sufficient carrying capacity in view of the

load.

•Use only the extensions delivered and mount them

according to the description contained herein.

•Check the unit for safe mounting of extensions before

operating it.

•Persons unable to operate the appliance due to their

physical, sensory or mental abilities or their

inexperience or lack of knowledge must not operate

it.

•If the appliance, feeder cable or steel cable show any

sign of visible damage the appliance must not be put

into operation.

•If the feeder cable of the appliance is damaged it

needs to be replaced by the producer or an

electrician.

•Repairs of the appliance can only be executed by an

electrician. There might be significant risks as a

result of unauthorised repairs.

•The same regulations apply for accessories.

Güde GmbH & Co. KG does not answer for damages

caused by:

•Appliance damage by mechanical influences and

overloading.

•Any changes to the appliance.

•Use for any other purpose than that described in the

Operating Instructions.

•Unconditionally follow all safety instructions to

prevent accidents and damage.

Emergency Action

Apply the first aid adequate to the injury and get qualified

medical assistance as quickly as possible. Protect the injured

person from more accidents and calm him/her down.

For the sake of eventual accident, in accordance with DIN

13164, a workplace has to be fitted with a first-aid kit. It is

essential to replace any used material in the first-aid kit

immediately after it has been used. If you seek help, state

the following pieces of information:

1. Accident site

2. Accident type

3. Number of injured persons

4. Injury type(s)

Disposal

Disposal instructions are given by pictographs on the unit or

packaging. For meaning of individual symbols refer to chapter

“Symbols on Unit”.

Operator Requirements

The operator shall read the instruction manual carefully

before using the unit.

Qualification

No special qualification is required for use of the unit except

for detailed direction by a professional.

Minimum Age

Only persons above 18 years of age are allowed to work with

the unit. Exempted from the provision is the use of the

juvenile trainees if they work in the course of their

professional training with an aim to obtain the skill under a

trainer supervision.

Training

Use of the unit requires adequate lesson by a professional or

the use of the manual only. Special training is not required.

Technical Data

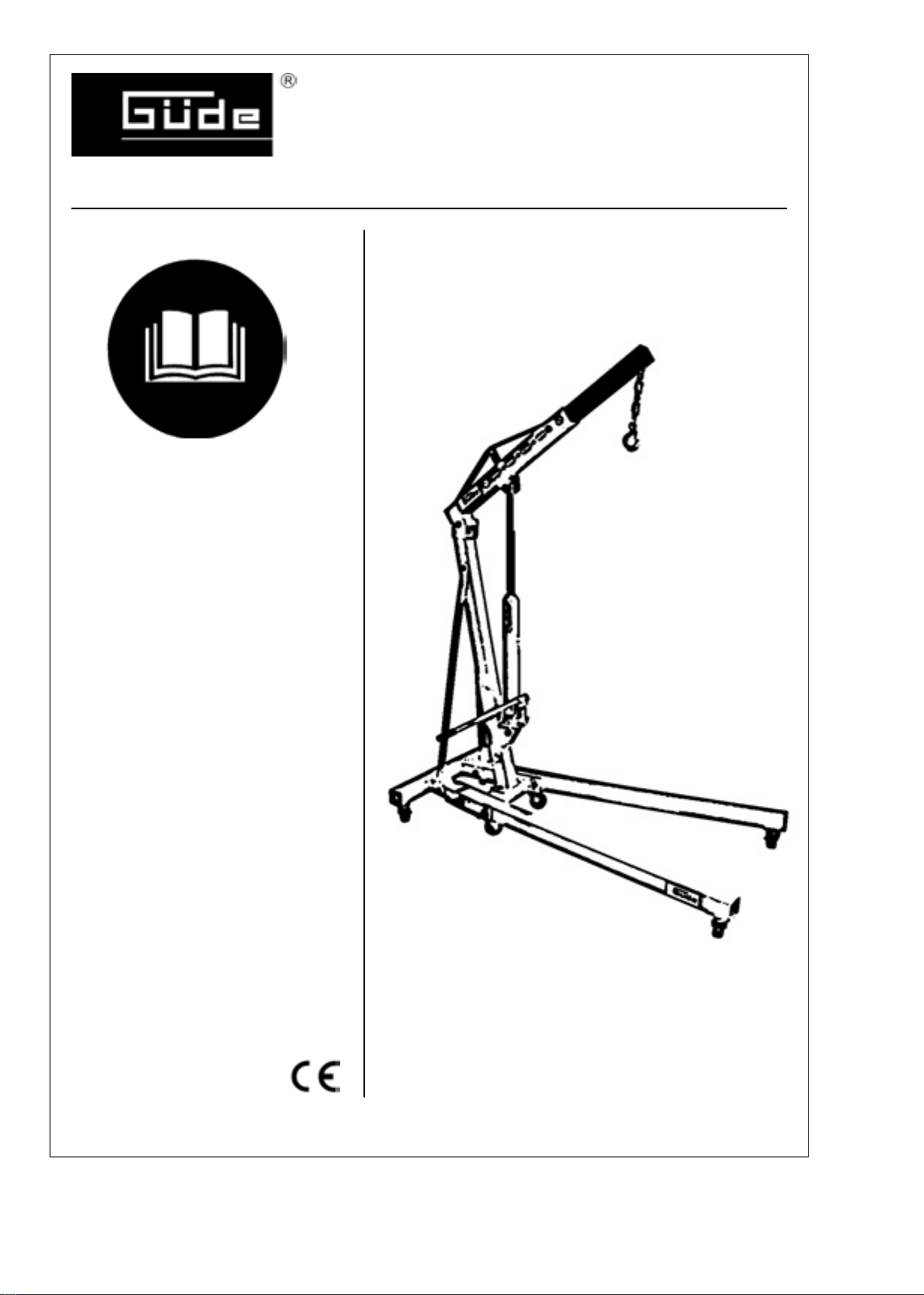

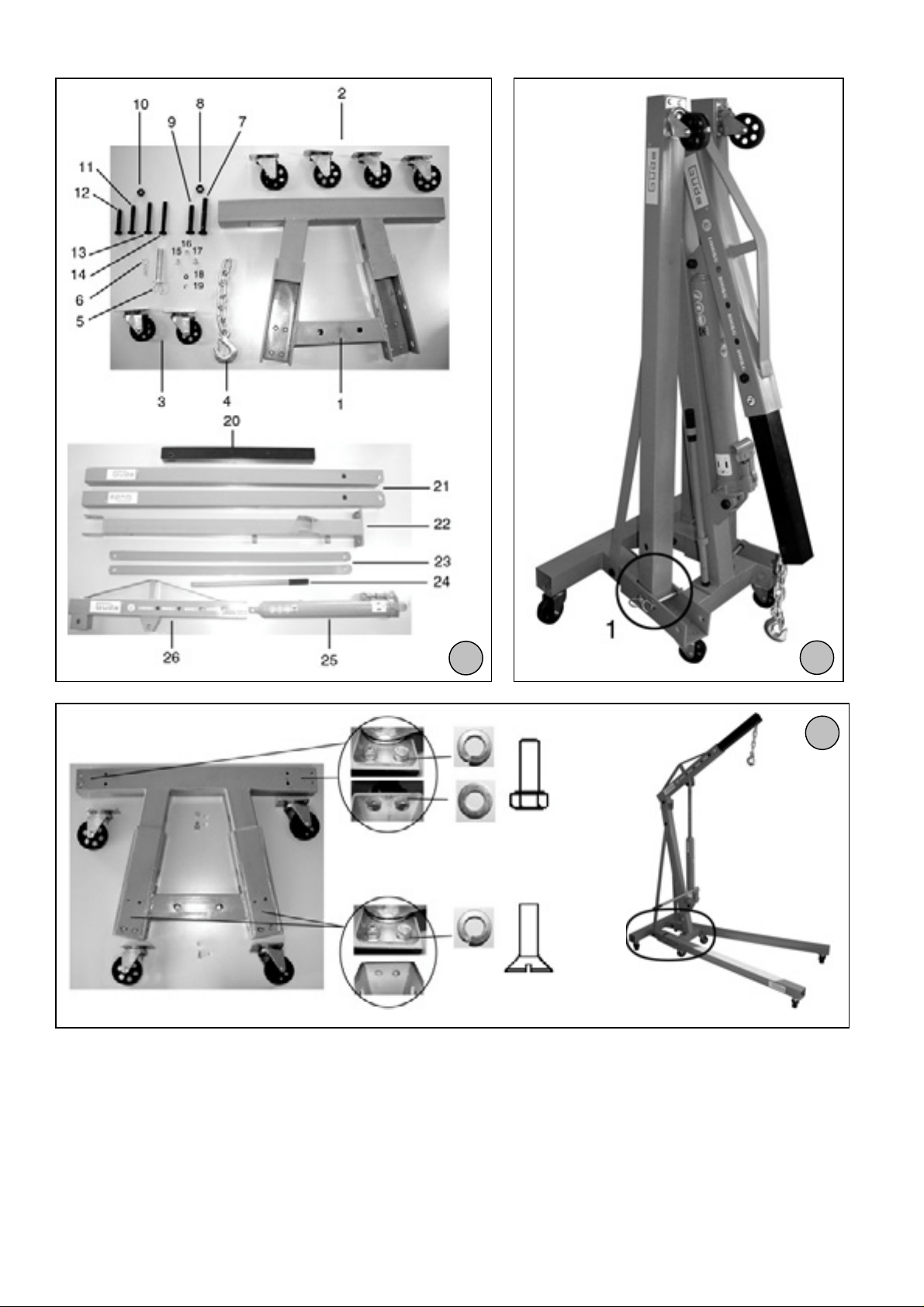

GWK 1000

Maximum carrying capacity: 1000 kg

Jib length: 870 – 1140 mm

Maximum lifting height: 2000 mm

Base dimensions (lxw): 1620 x 810 mm

Folded crane dimensions (lxwxh): 550 x 700 x 1490 mm

Weight ca: 70 kg

Ordering No.: 24360