5

6

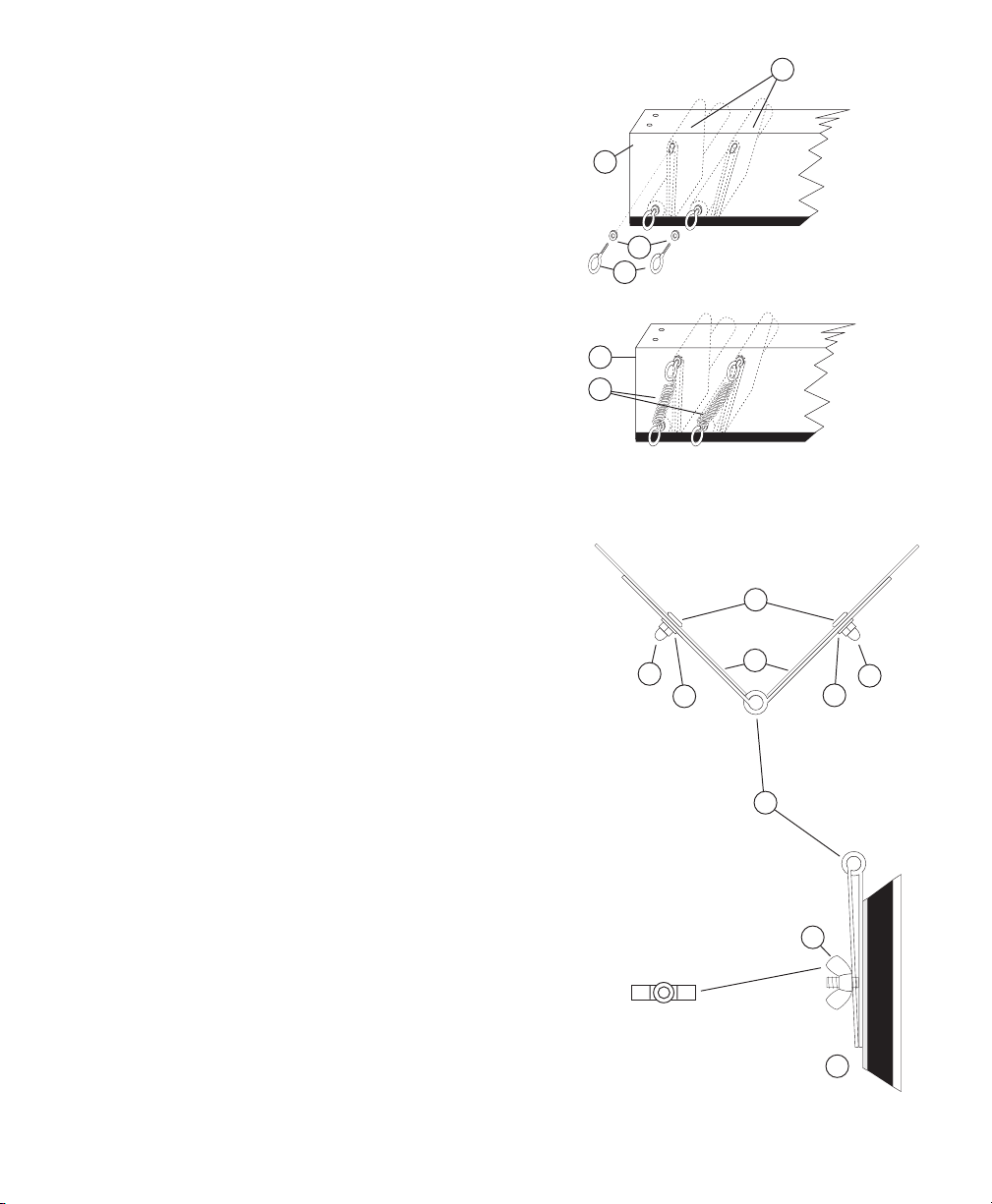

Install Acorn Nuts on outside of

forward Spreader Bar Assembly

for mortar applications.

Install Wing Nuts on back side of

Spreader Bar Assemblies for grout-

ing applications.

After assembly, orient the Wing Nut

horizontally with the Spreader Bar

Assembly to avoid contact with the

Stabilizer Tube Assembly.

Matching

Trowel Blades

Grout Float Pad

17 21

16

19

20

5

18

17

18

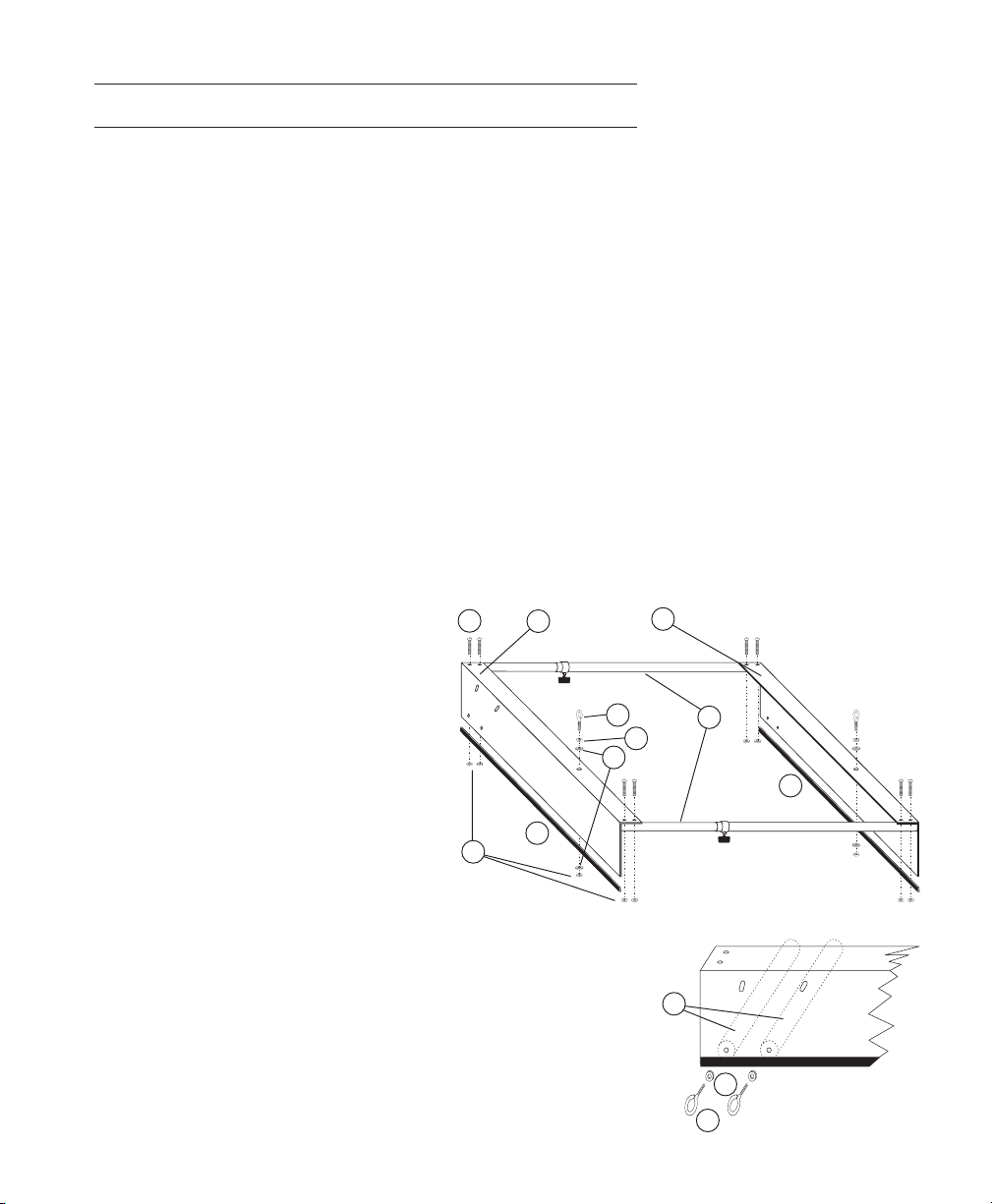

6. Install four 3" Nylon Wipers (9; not shown) to the edges of

both Spreader Bar Assemblies (5) that always contact the

Frame Angles. These four edges are the two edges of both

Spreader Bar Assembly blades with the brass insert, and

the two edges at the opposite end of both Spreader Bar

Assembly blades without the brass insert.

7. Orient Spreader Bar Assemblies so the ends with brass

inserts face the Right Hand Frame Angle (1).

8. Install a Spreader Bar Assembly (5) to the front oblong hole

using a 1/4-20 Eye Bolt (14) and Washer (13) on the end

with the brass insert, and a 1/4" Eye Screw (15) and Washer

(13) on the other end.

9. Repeat Step 8 to install the rear Spreader Bar Assembly.

10. Tighten Eye Bolts and Eye Screws until snug, then back off

about 1/2 turn.The Spreader Bars should move up and down

freely in the oblong holes.

11. Attach four Coil Springs (6) from the Spreader Bar Eye Bolts

to the Stabilizer Tube Eye Bolts on each side of the frame as

shown at right.

12. Attach the Strap with Bolt Snaps (7; not shown) to the Eye

Bolts on the top of the frame.

Setting Up Superspreader System

for Mortar Spreading Application

1. Remove Grout Float Pads. (Store Wing Nuts on the float

studs.)

2. Turn Superspreader Frame over and open forward Spreader

Bar Assembly (5).

3. Orient two matching Trowel Blades (21) so that the ends have

notches against each Frame Angle.

4. Install trowel blades to the inside of the forward Spreader

Bar Assembly using six Weld Screws (16), six washers (18),

and six High Crown Acorn Nuts (17). Install these screws

from the inside out with Acorn Nuts on the outside. Leave nuts

loose until you turn the Superspreader Frame over and make

sure bottoms of both blades are flush with a flat surface.

5. Tighten Acorn Nuts (no need to hold screws on inside while

tightening).

Setting Up Superspreader System

for Grout Spreading Application

1. Remove Trowel Blades from the forward Spreader Bar Assembly.

2. Close (adjust) frame width until the holes in the Spreader

Bar Assemblies line up.

3. Install Grout Float Pads (20) to the front and rear Spreader

Bar Assemblies with Wing Nuts (19).

Orient horizontally and

do not overtighten.

15

13

2

2