Page 2

P18690

09/28/2009

HH..KK.. PPoorrtteerr®

8690 Series Disassembly and Assembly

The following disassembly and assembly procedures

apply to all models except where noted.

Disassembly:

1. Secure the tool in a vise by the right handle (handle

without the ratchet) with the left handle parallel to the

floor and the head pointing away from you.

2. TN model: Cut the rubber handle grip (P0380 ) from

the handle. Be careful not to damage the plastic sleeve.

3. FH, FSK, CK, and CS models: In the end of the left

handle (the ratcheting handle), insert a hook type tool

through the access hole in the end of the handle grip,

hook the spring, pull the spring slightly towards you,

twist 90 degrees and unhook the spring (P8678FS)

from the pin. Note: removal of the handle grip is no

longer required as a result of the added access hole to

the new grip.

3a. TN model: Unhook the spring extension (P8679TN)

from the pin on the ratchet handle using a hook type

tool.

4. Loosen nut (T3171) from bolt (P8635FS) using 7/16”

wrenches.

5. Remove the bolt and snubber (P8654FS).

6. Remove the tool from the vise.

7. Unhook the two closing springs (P8658FH).

8. Remove the closing spring bolt (P8634FS), nut

(T3171) and snubber (P8654FS).

9. Remove the cutterhead from the handles using 9/16”

wrenches. Important: Note the difference in length

between the two sets of bolts.

10. Remove the right handle assembly, with the chain

and spring still attached, from the left handle.

11. Remove the nut (P2666K) from the sprocket pivot

bolt (P8692FS) using a 9/16” wrench.

12. Remove the sprocket pivot bolt (P8692FS).

13. Remove the two side plates (P8621FS), sprocket

(P8624FS), bushing (P8642FS), detent pawl

(P8637FS), and spring (P8677FS).

14. Remove the two crank plate bushings (P8646FS).

15. Clean all parts thoroughly with solvent.

Assembly:

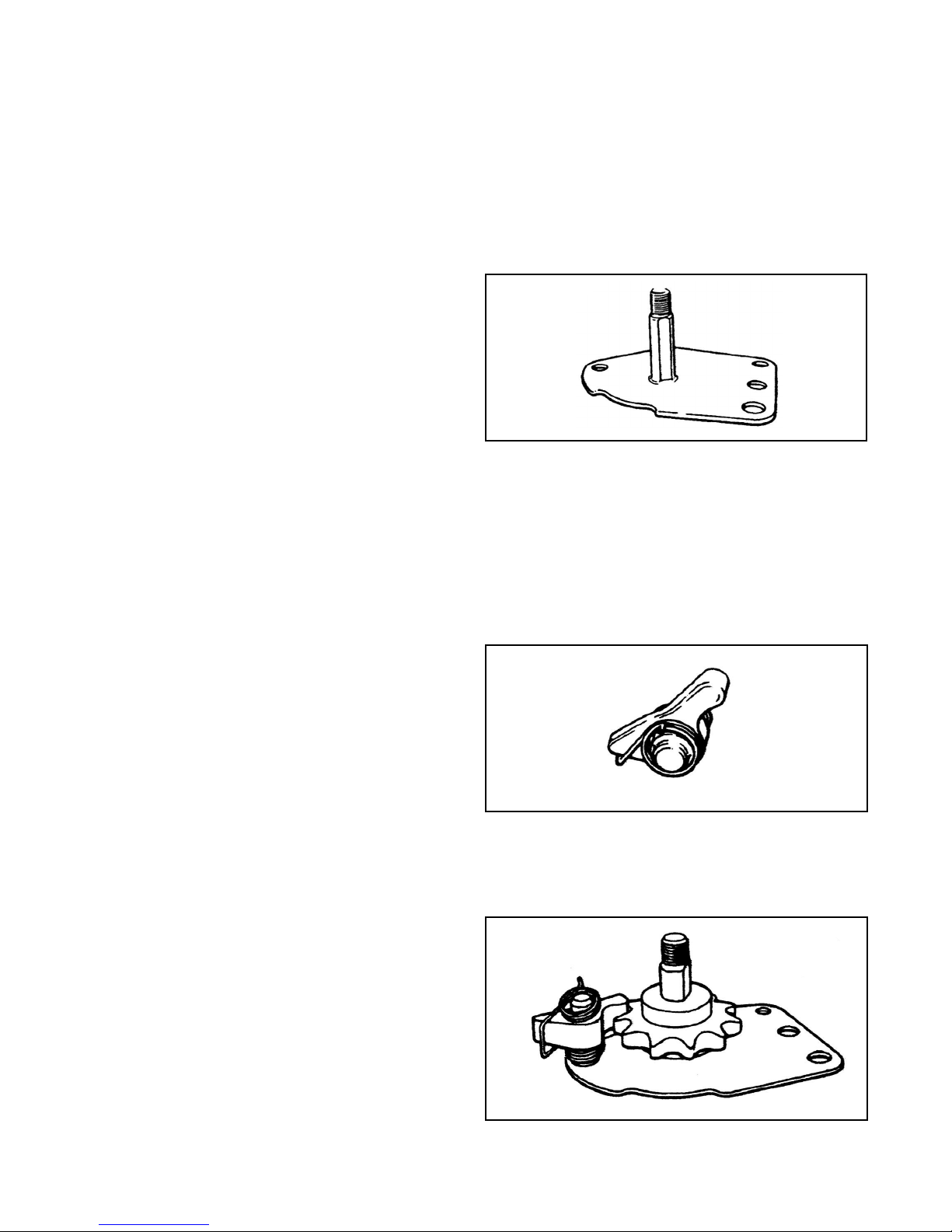

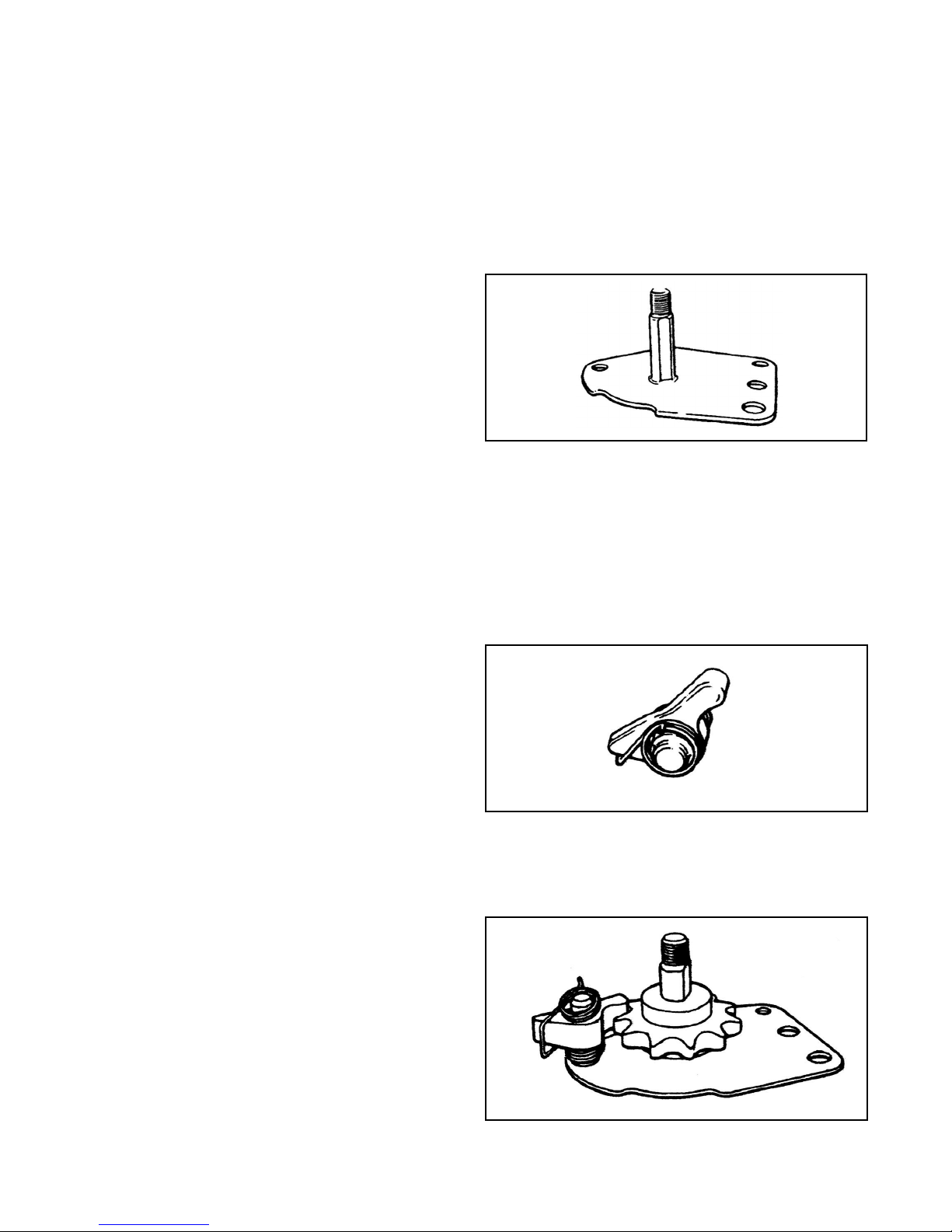

1. Assemble the pivot bolt (P8692FS) to one of the side

plates (P8621FS). atch the flat on the bolt with the flat

in the plate hole. Lay this assembly on the bench with

the bolt head down and the notched edge of the plate

nearest to you. See Illustration 1.

2. Apply a light film of grease to the shank of the pivot

bolt.

3. Slide the sprocket (P8624FS) onto the pivot bolt.

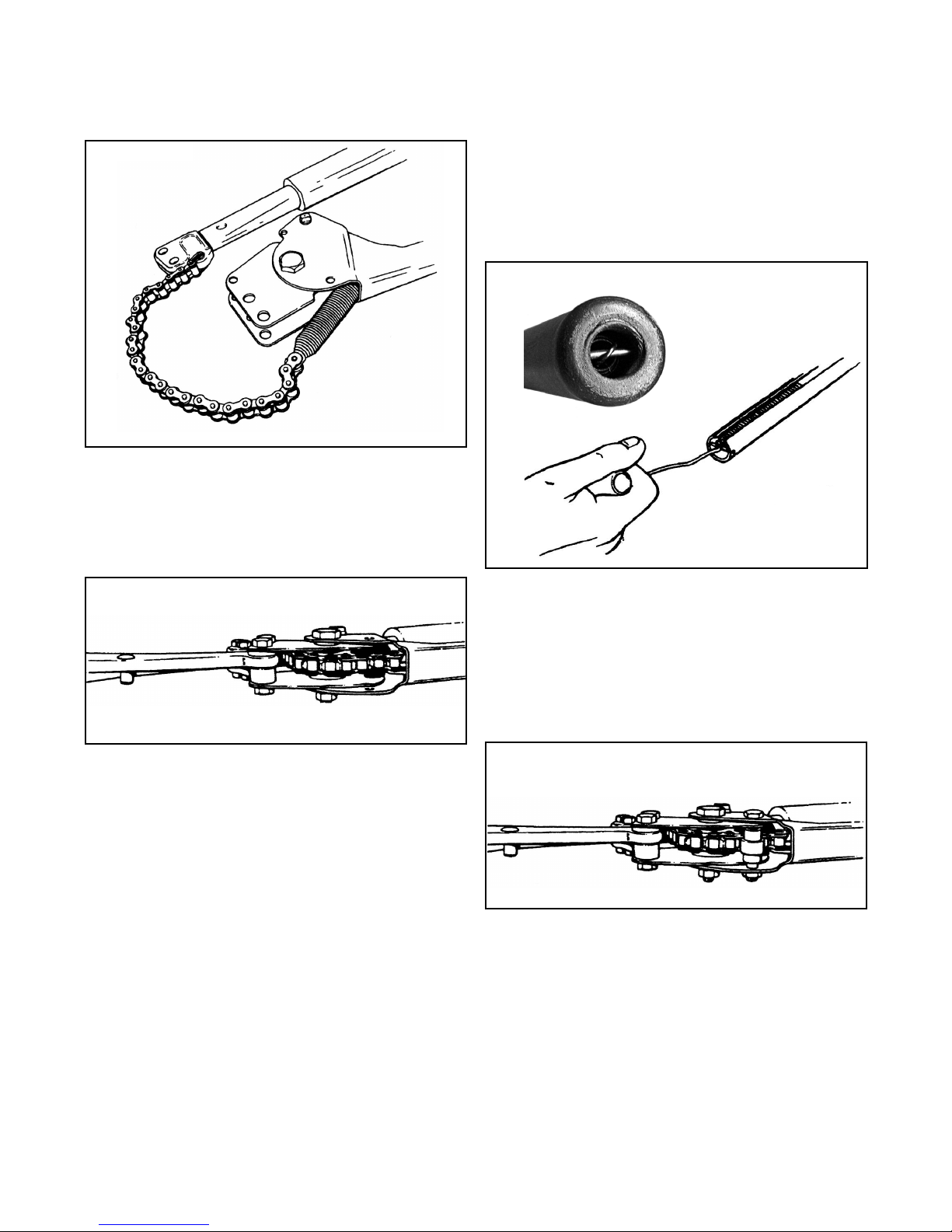

4. Apply grease to the detent spacer bushing

(P8642FS) and slide into the detent pawl. Place the

detent spring (P8677FS) onto the pin making sure the

spring ends have not been bent out of shape. The cross

arm of the spring goes under the flat side of the narrow

shaped point of the detent pawl. See Illustration 2.

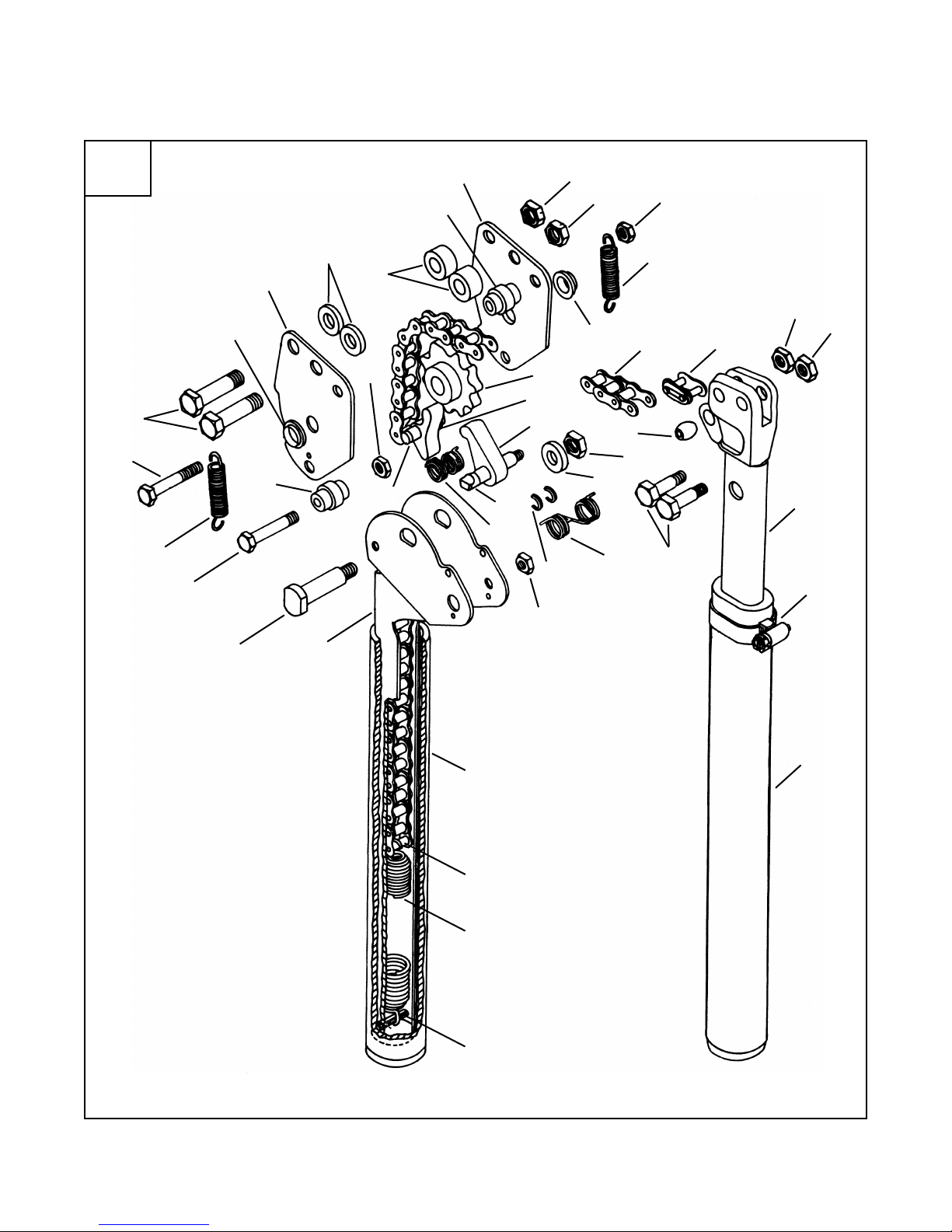

5. Assemble one end of the detent spacer bushing

(P8642FS) into the hole on the side plate (P8621FS)

and engage the rounded end of the pawl with the

sprocket (P8624FS). See Illustration 3.

Illustration 1

Illustration 2

Illustration 3