www.h2flow.net •Tel: 888-635-0296 (Toll Free) OR (+1) 419-841-7774 (International)

table of contents

Description .............................................................................................................3

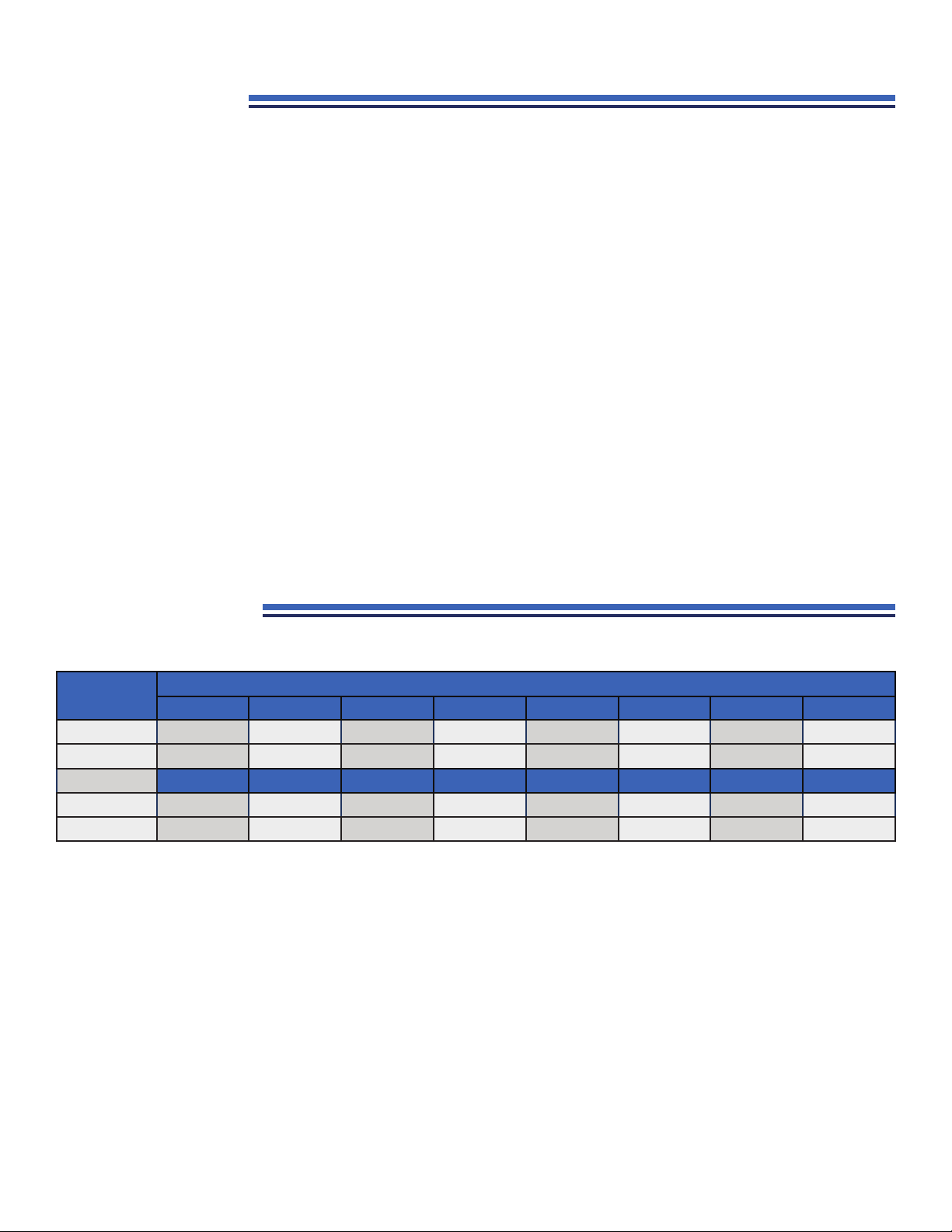

Flow Ranges ..........................................................................................................3

Technical Data ......................................................................................................4

Dimensions.............................................................................................................5

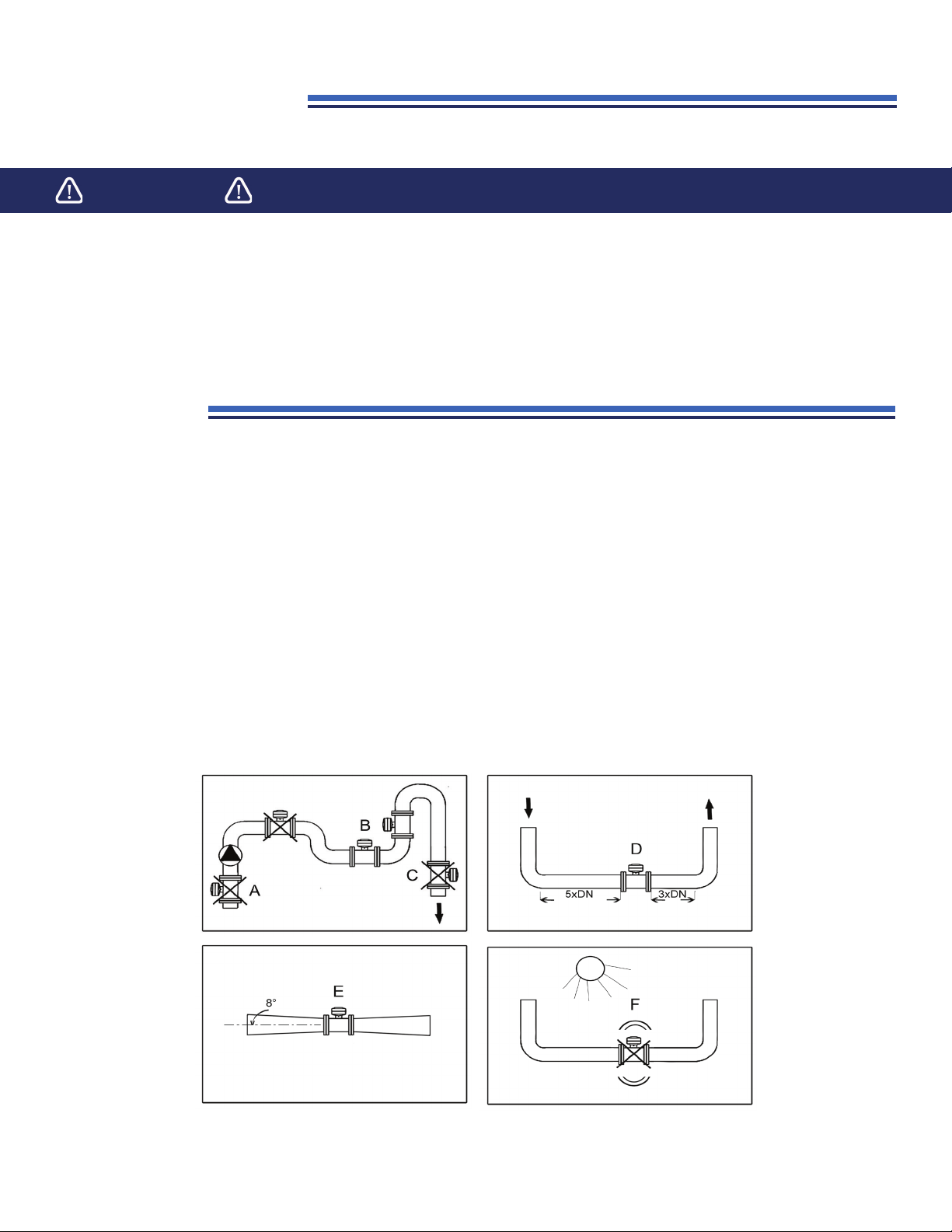

Installation Note ....................................................................................................6

Location ...................................................................................................................6

Electrical Connections ......................................................................................7

Instrument Start ...................................................................................................9

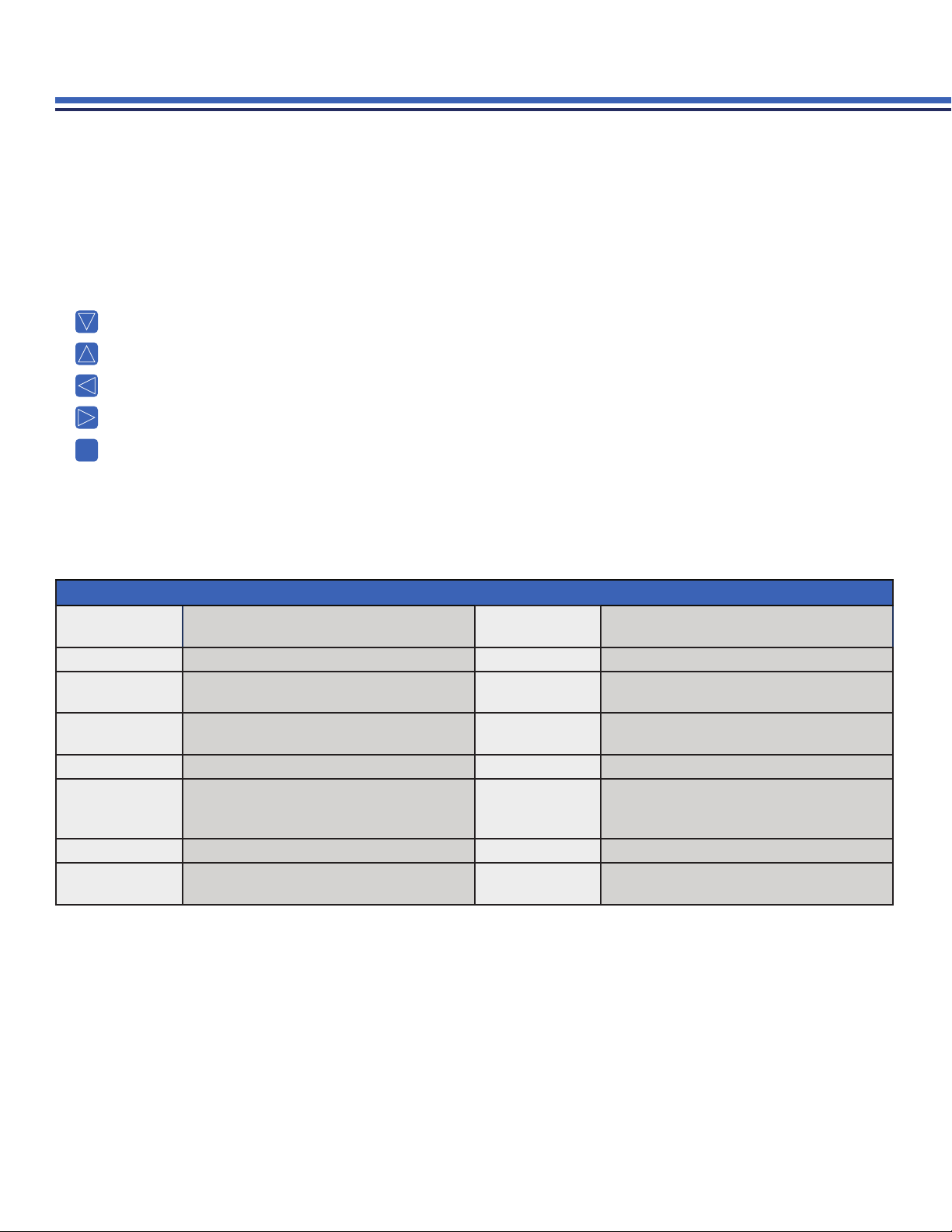

Instrument Configuration ................................................................................9

A. menu options, commands........................................................................ 10

B. multi-functional outputs............................................................................. 11

B-1. pulse setting .................................................................. 11

B-2. status report setting ................................................... 12

C. analog output............................................................................................... 12

D. display ................................................................................................... 13

E. damping ................................................................................................... 13

F. dead band setting ....................................................................................... 14

G. datalogger ................................................................................................... 14

G-1. datalogger setting without time mask................... 15

G-2. datalogger setting with time mask........................ 15

G-3. examples of time mask setting............................... 16

G-4. datalogger sub-menu................................................ 16

H. function of the third electrode................................................................ 17

I. password setting........................................................................................... 17

J. GSM module activation.............................................................................. 18

Troubleshooting...................................................................................................18

Notes.........................................................................................................................19

Warranty .................................................................................................................. 20

2

SECTION

1

2

3

4

5

6

7

8

9

10

11

12