table of contents

1. General Information......................................................... 3

1.1 Description.....................................................................3

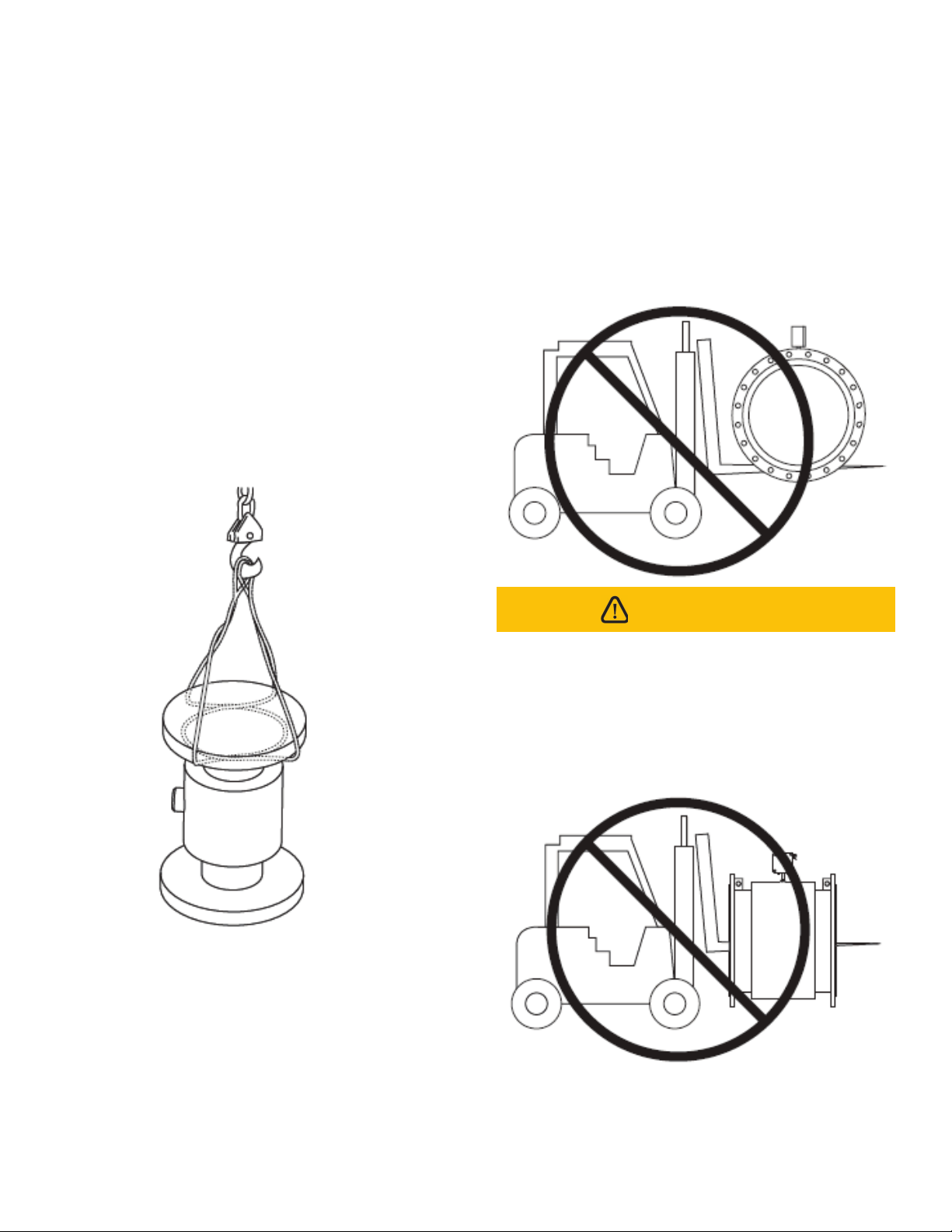

1.2 Unpacking and Inspection........................................4

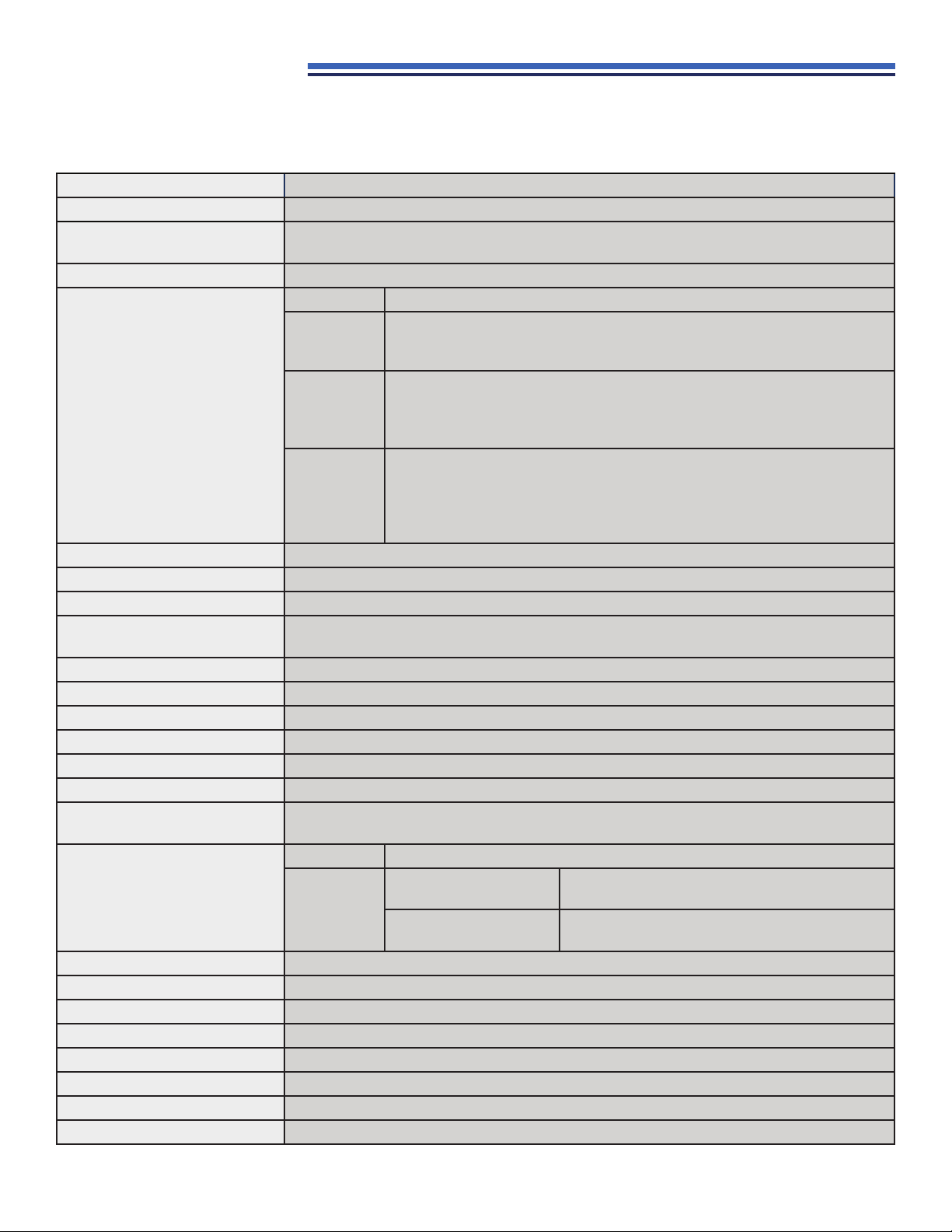

2. Technical Data .................................................................. 5

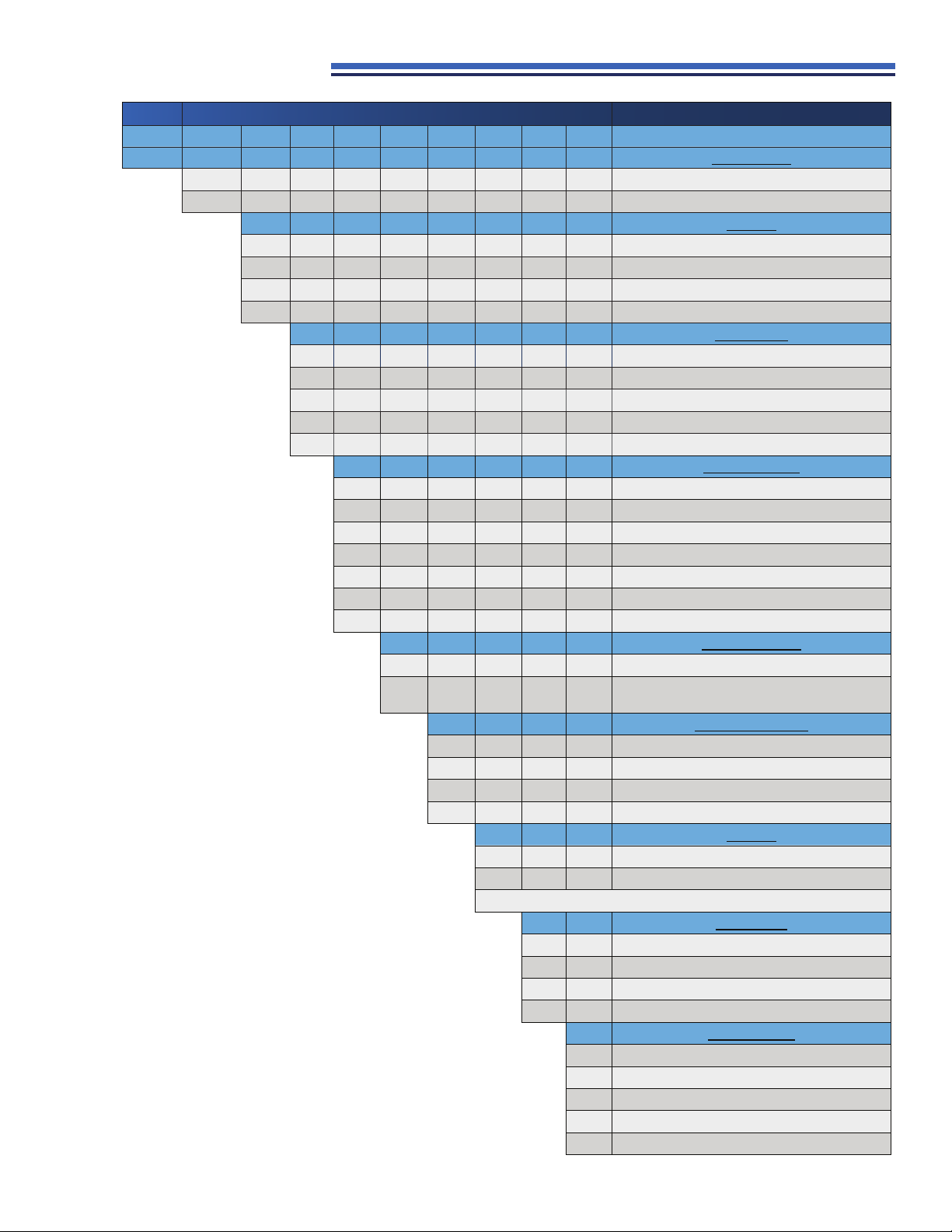

3. Measurable Flow Ranges ............................................... 6

4. Model Selection................................................................ 7

5. Installation Considerations............................................. 8

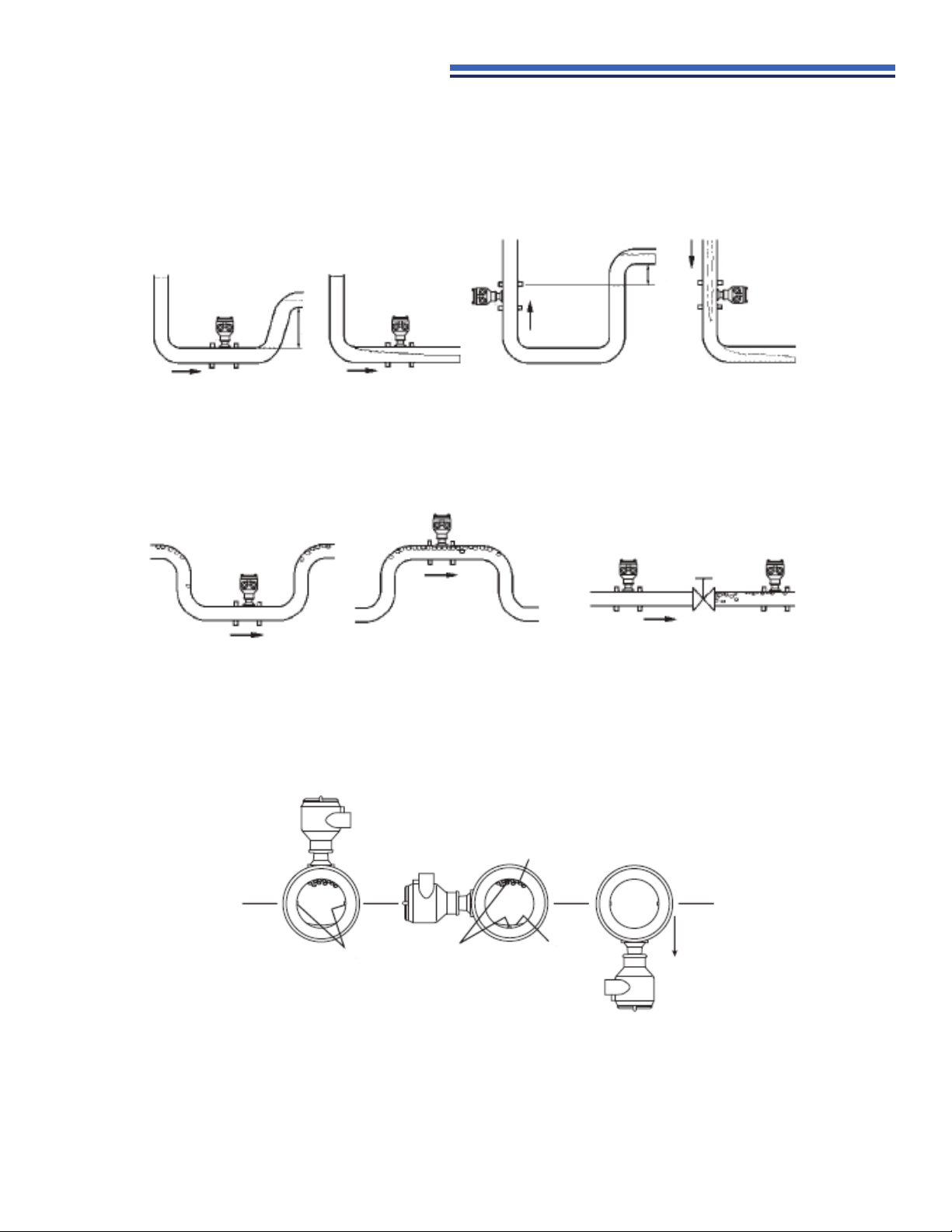

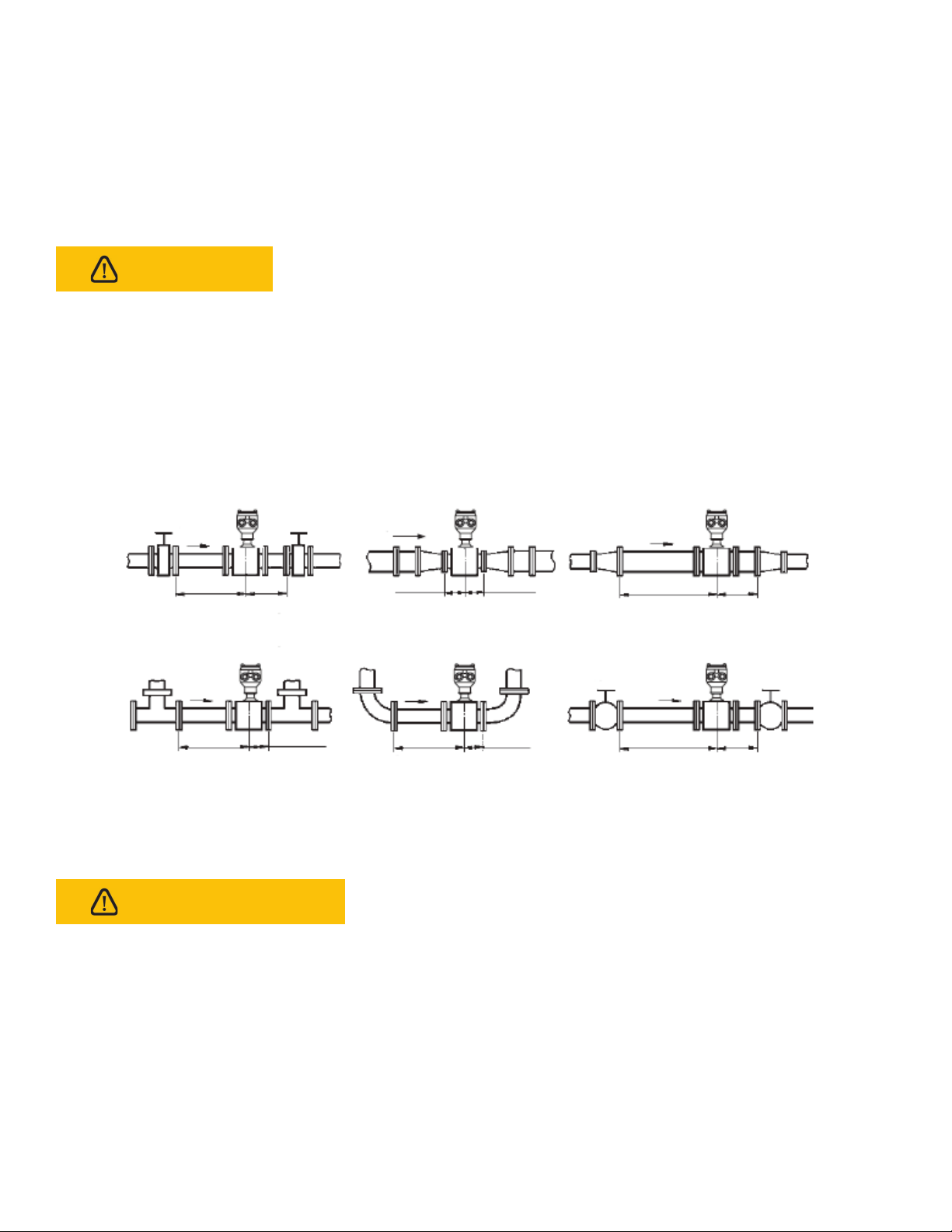

5.1 Mounting Positions......................................................8

5.2 Required Lengths of Straight Runs ........................9

5.3 Grounding ......................................................................10

5.4 Connections ..................................................................10

6. Converter Connection..................................................... 13

6.1 Terminal Wiring and Marking (Compact Type)....13

6.2 Terminal Wiring and Marking (Remote Type) ......14

6.3 Connection Wire and Cable Characteristics

and Connection Requirements ...............................14

6.4 Output and Power Cord ............................................15

7. Setting Parameters .......................................................... 18

7.1 Flow Setup.....................................................................18

7.2 Alarm Setup...................................................................22

7.3 Output Setup.................................................................24

7.4 Sensor Setup.................................................................26

7.5 Communication Setup................................................27

7.6 Parameter Modification Tag......................................27

8. Instrument Display and Operation................................ 28

8.1 Key Function and Remote Control Function

(Compact Type) ............................................................28

8.2 Key Function and Remote Control Function

(Remote Type)...............................................................29

8.3 Function Selection Screen and Parameter

Setting Operation ........................................................31

9. Product Performance and Indicators ........................... 32

9.1 Basic Functions ............................................................32

9.2 Special Functions ........................................................32

9.3 Normal Working Conditions .....................................32

9.4 Connection Method with Sensor............................32

9.5 Sensor Matching Requirements..............................32

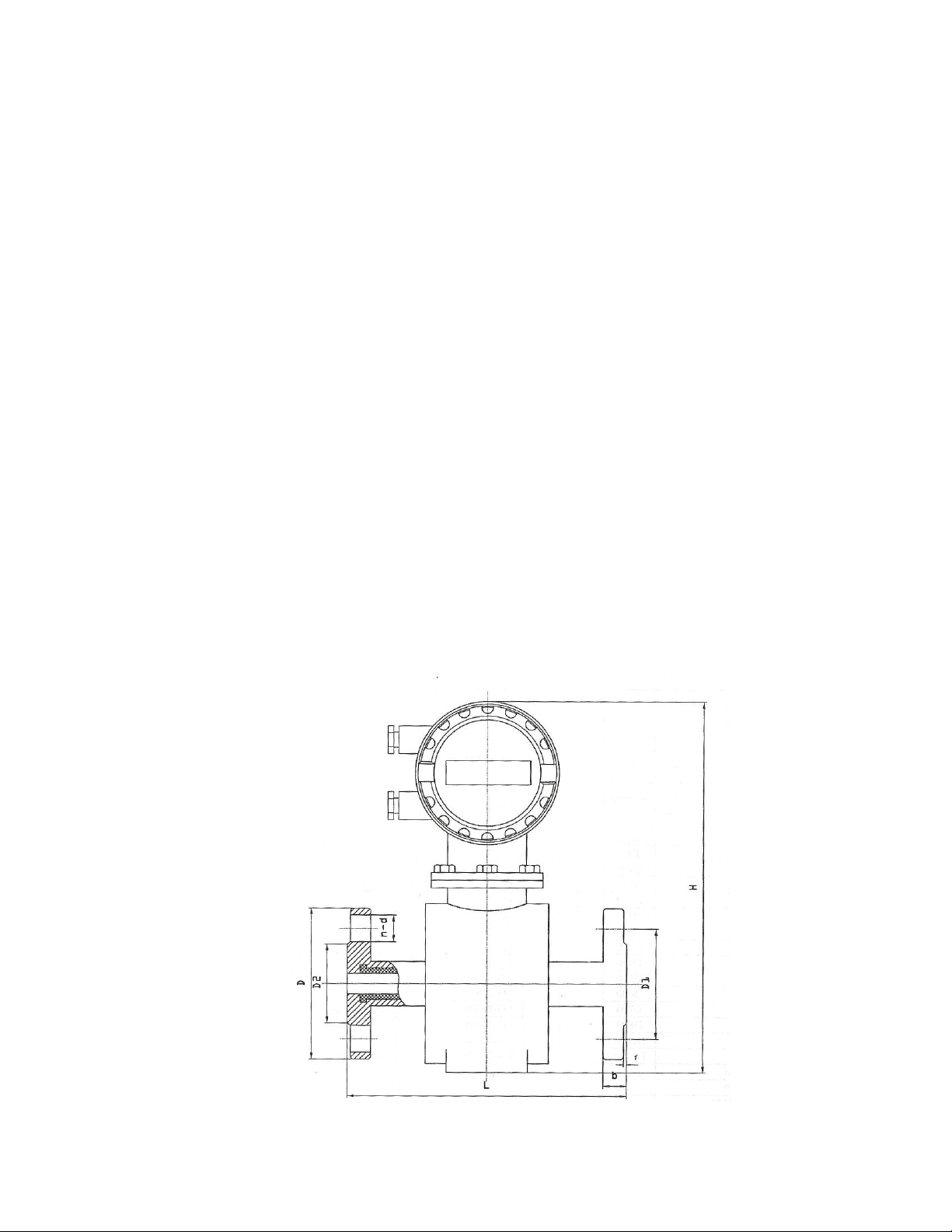

9.6 Installation Dimension Drawing...............................33

9.7 Measuring Accuracy...................................................34

9.8 Analog Current Output ..............................................35

9.9 Digital Frequency Output..........................................35

9.10 Digital Pulse Output ....................................................35

9.11 Alarm Output.................................................................35

9.12 Digital Communication Interface and

Communication Protocol...........................................35

9.13 Electrical Isolation........................................................36

9.14 Digital Output and Calculation ................................36

9.15 Analog Output and Calculation...............................38

10. Alarm Information ............................................................ 40

11. Troubleshooting ............................................................... 40

12. Storage ........................................................................ 41

Appendix I Non-linear Correction Function Description... 41

Appendix II List of Instrument Menus.................................... 43

Appendix III Passwords ............................................................. 46

Product Warranty ........................................................................ 47