i

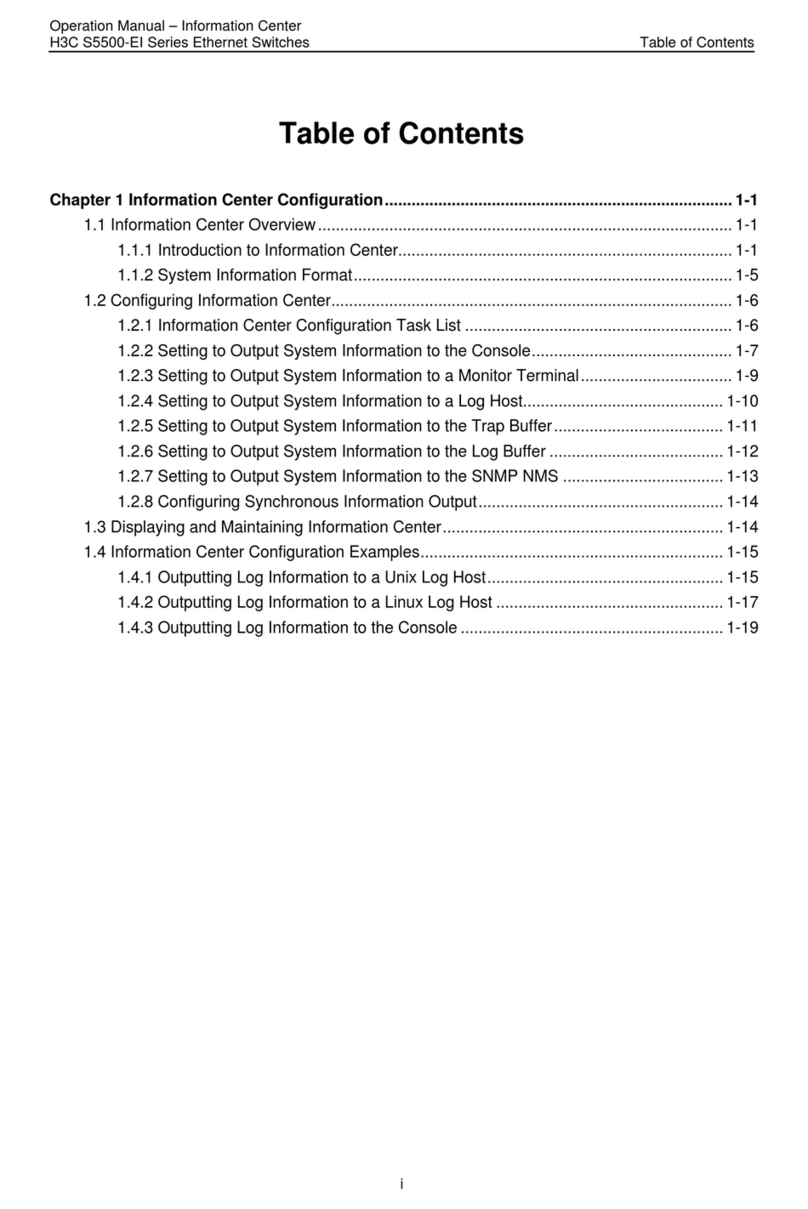

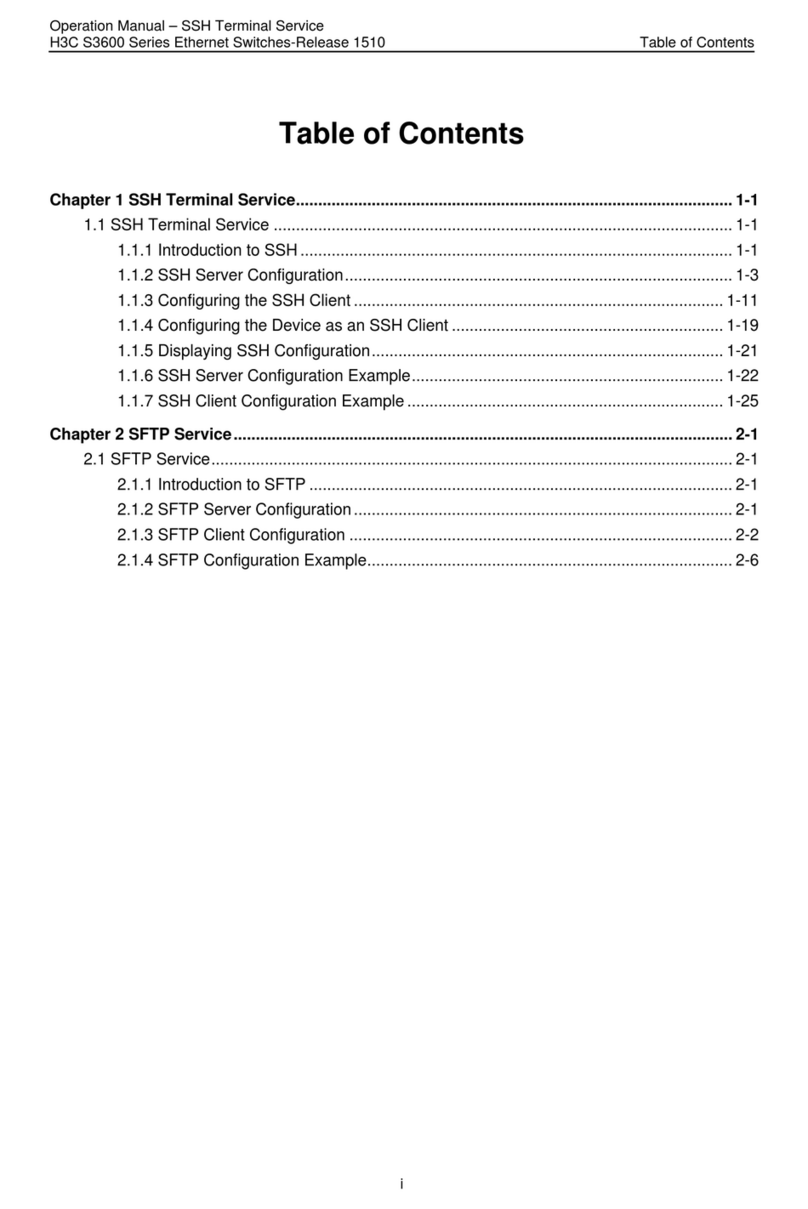

Contents

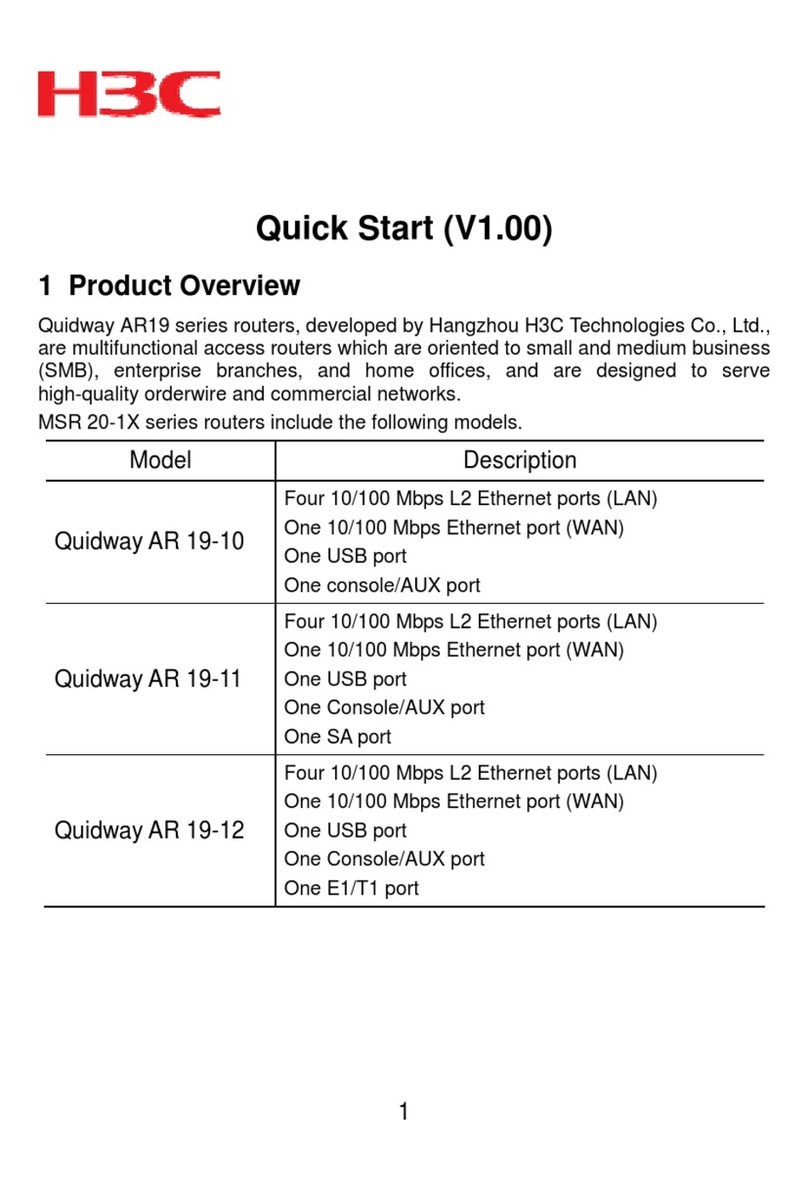

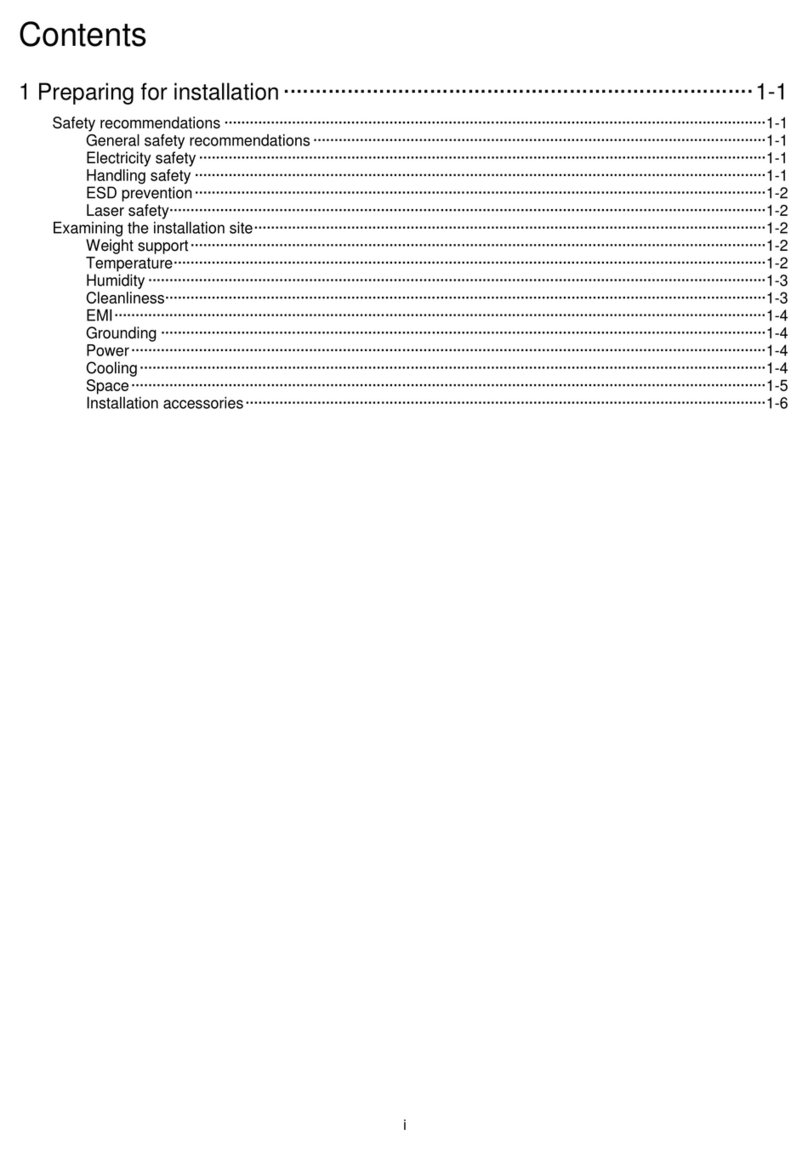

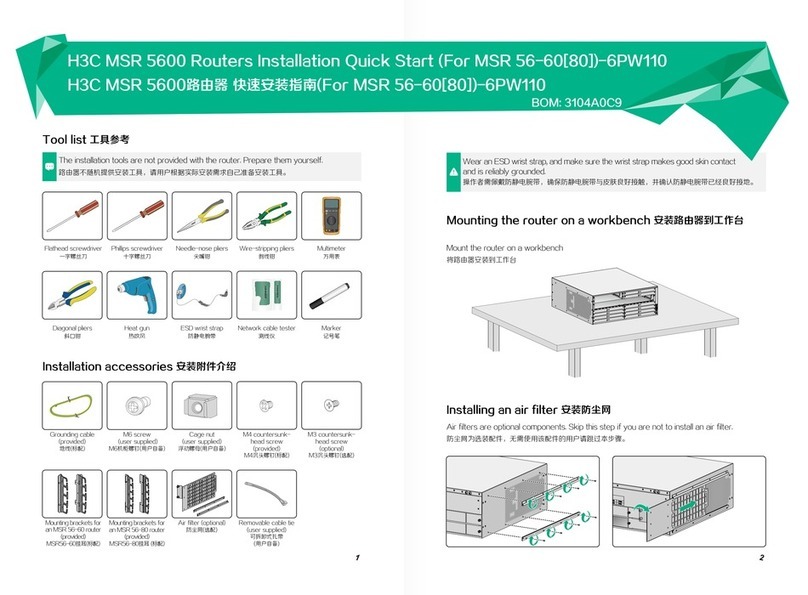

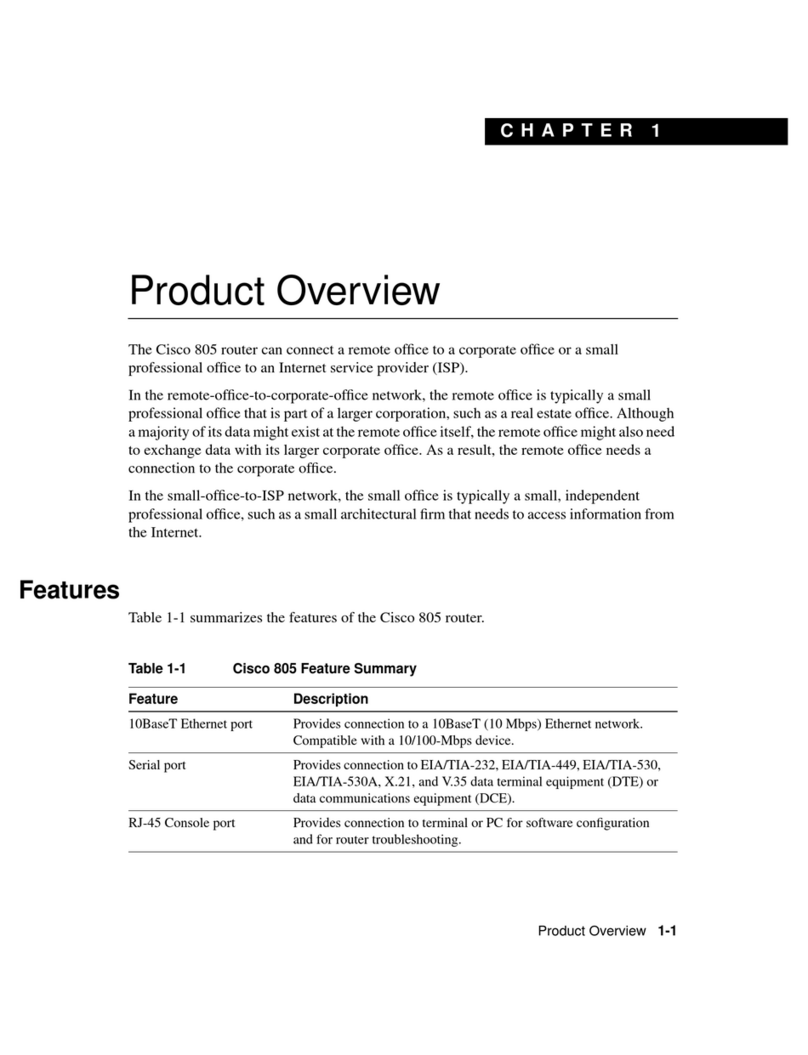

1 Preparing for installation·············································································1

ESD prevention··················································································································································1

Examining the installation site····························································································································1

Installation tools and equipment ························································································································1

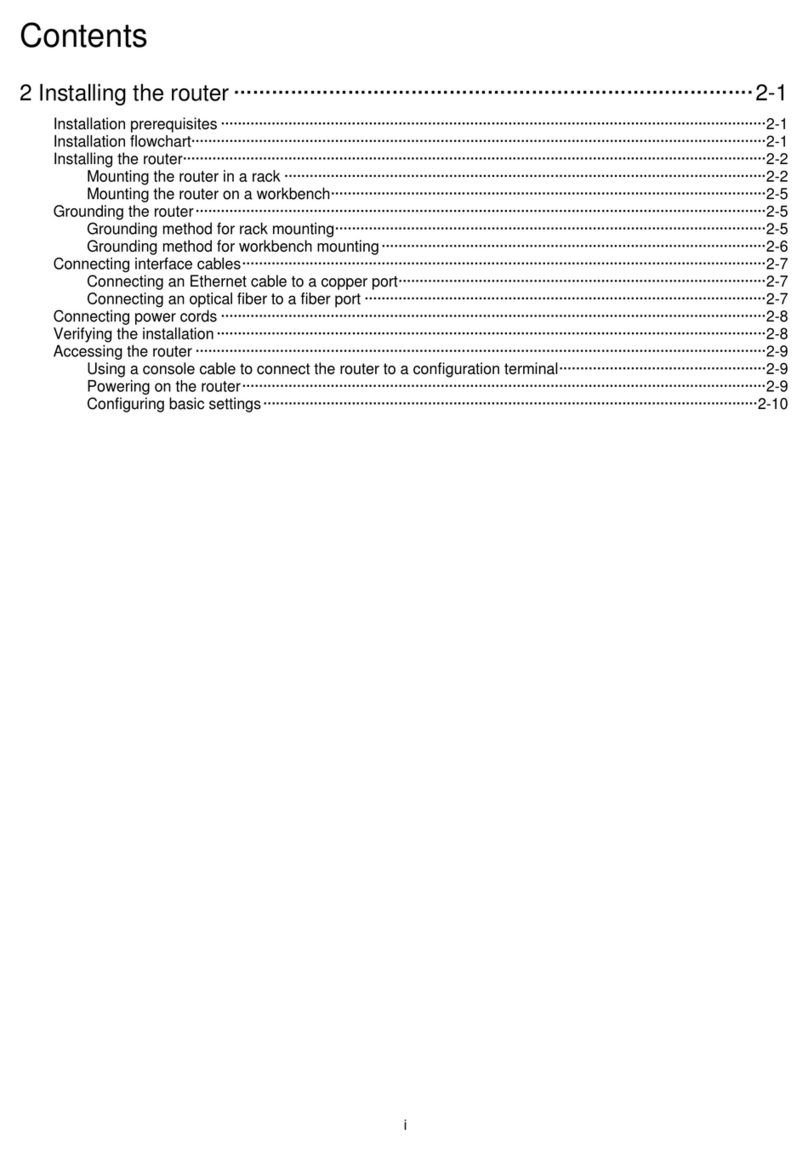

2 Installing the device····················································································2

Device dimensions·············································································································································2

Rack requirements·············································································································································3

Slide rail requirements ·······································································································································3

Installing cage nuts for attaching mounting brackets·························································································3

Mounting the device in a rack ····························································································································4

Grounding the device·········································································································································6

3 Installing removable components································································7

Attaching an ESD wrist strap ·····························································································································7

Installing cable management brackets···············································································································7

Installing SEUs···················································································································································9

(Optional.) Replace environment management modules·················································································10

Installing interface modules······························································································································11

Installing fabric modules···································································································································12

Installing fabric modules···························································································································12

Installing a filler panel in a fabric module slot···························································································15

Removing a filler panel from a fabric module slot····················································································17

Installing fan trays············································································································································18

Installing a fan tray···································································································································18

Removing the filler panel from a fan tray slot···························································································19

Installing power supplies and power trays ·······································································································21

Power trays and power supplies··············································································································21

Installing a power supply··························································································································21

Connecting power cords ··························································································································22

(Optional) Installing power trays···············································································································24

Installing the air filter in the top hood ···············································································································26

Installing transceiver modules··························································································································27

Installing a transceiver module·················································································································27

Connecting an interface cable··················································································································28

4 Cabling recommendations········································································29

5 Accessing the device················································································30

Connecting the console cable··························································································································30

Verification before login····································································································································30

Viewing device startup information ··················································································································31