3

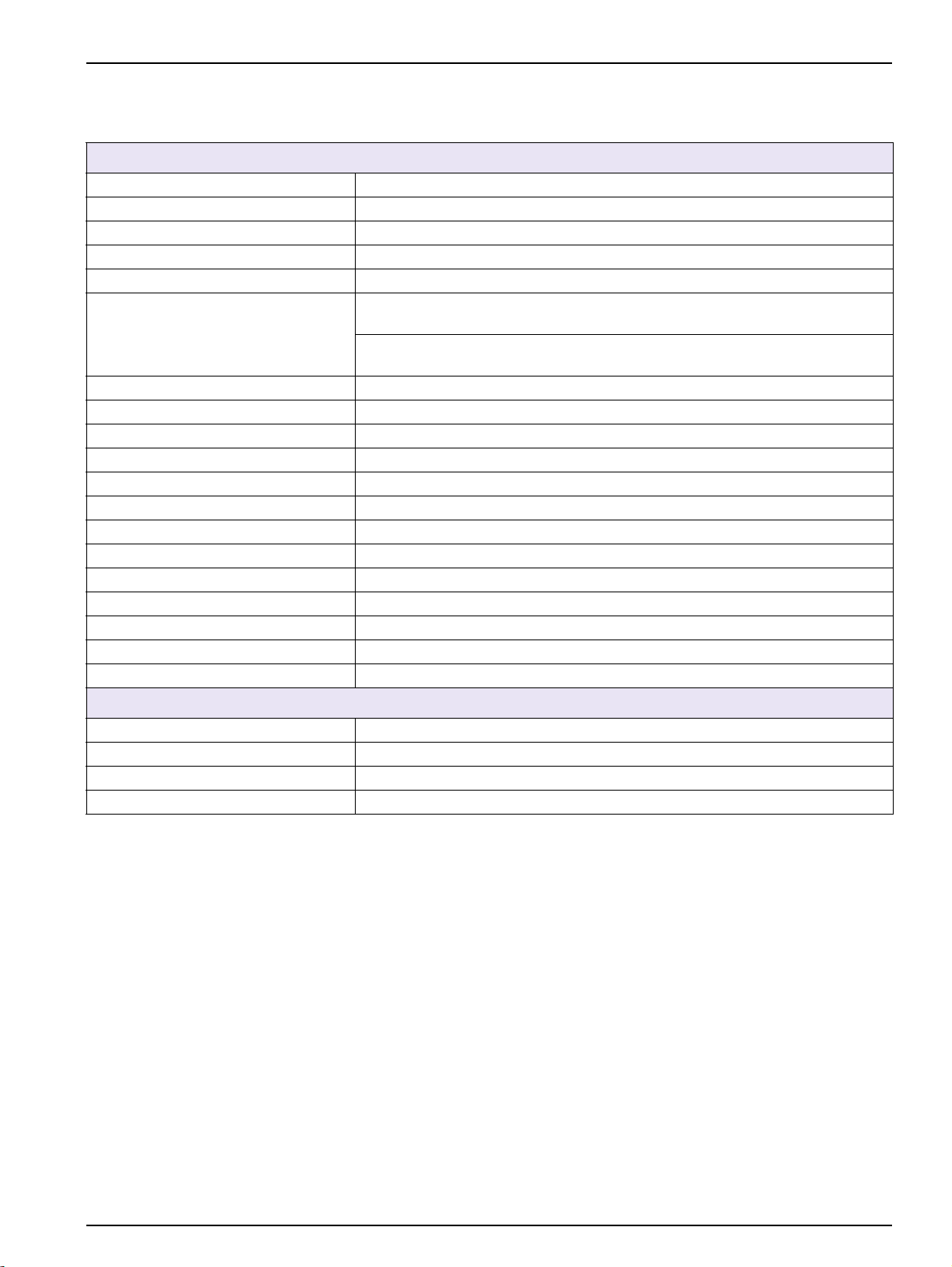

Table of Contents

Section 1 Specifications....................................................................................................................5

Section 2 General Information.........................................................................................................7

2.1 Safety information........................................................................................................................7

2.1.1 Use of hazard information...................................................................................................7

2.1.2 Precautionary labels ...........................................................................................................7

2.1.3 Laser safety information...................................................................................................... 8

2.1.4 Battery safety information...................................................................................................8

2.1.5 Electrostatic discharge (ESD) considerations.....................................................................8

2.2 General product information ........................................................................................................9

2.3 Theory of operation......................................................................................................................9

Section 3 Installation........................................................................................................................11

3.1 Unpack the instrument...............................................................................................................11

3.2 Installation guidelines for the MET ONE 227 particle counter ...................................................11

3.3 Mechanical installation...............................................................................................................12

3.3.1 Install the isokinetic probe.................................................................................................12

3.3.2 Install the purge filter.........................................................................................................12

3.3.3 Install the charging stand..................................................................................................13

3.3.4 Connect the AC adapter ...................................................................................................13

3.3.5 Install the RH/T probe.......................................................................................................13

3.4 Connections and adjustments....................................................................................................13

Section 4 Operation..........................................................................................................................15

4.1 Power up....................................................................................................................................15

4.2 Factory default settings..............................................................................................................15

4.3 Manual mode.............................................................................................................................15

4.4 Automatic mode.........................................................................................................................16

4.4.1 Unlock the program mode.................................................................................................19

4.4.2 Set display (DSP) functions..............................................................................................19

4.4.3 Set serial input/output (SIO) functions..............................................................................21

4.4.4 Set clock (CLK) functions..................................................................................................21

4.5 Average mode............................................................................................................................23

4.6 Concentration mode...................................................................................................................24

4.7 Beep mode.................................................................................................................................26

4.8 Program the temperature probe.................................................................................................28

Section 5 Maintenance ....................................................................................................................29

5.1 Maintenance guidelines.............................................................................................................29

5.2 Clean the sensor........................................................................................................................29

Section 6 Troubleshooting .............................................................................................................31

6.1 Common problems.....................................................................................................................31

6.2 Reset the counter.......................................................................................................................31

6.3 Troubleshoot the pump..............................................................................................................32

6.3.1 Disassemble and clean the pump.....................................................................................32

6.3.2 Optimize the pump............................................................................................................35

Section 7 Replacement Parts and Accessories.........................................................................37

7.1 Accessories................................................................................................................................37

7.2 Optional accessories..................................................................................................................37

Section 8 Service Contact Information........................................................................................39

Section 9 Limited Warranty ............................................................................................................40

Section 10 Certification...................................................................................................................41