Table of Contents

Section 1 Product overview................................................................................. 3

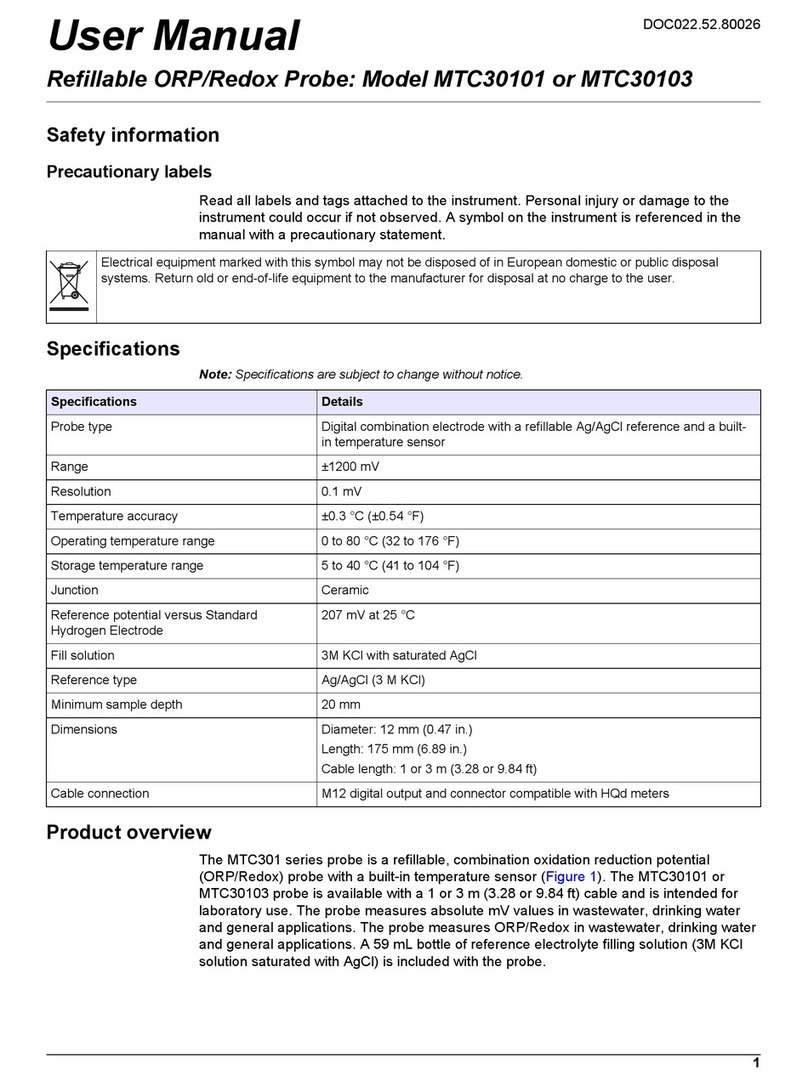

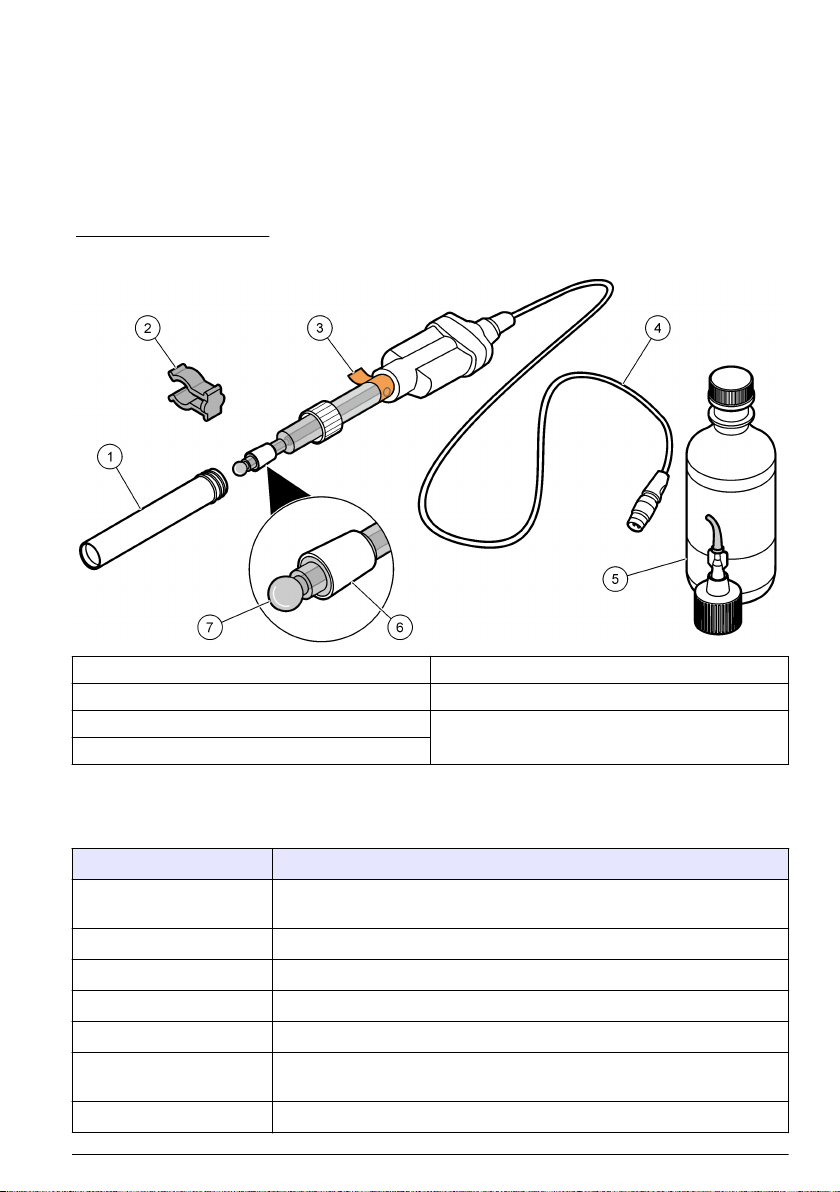

Section 2 Specifications........................................................................................ 3

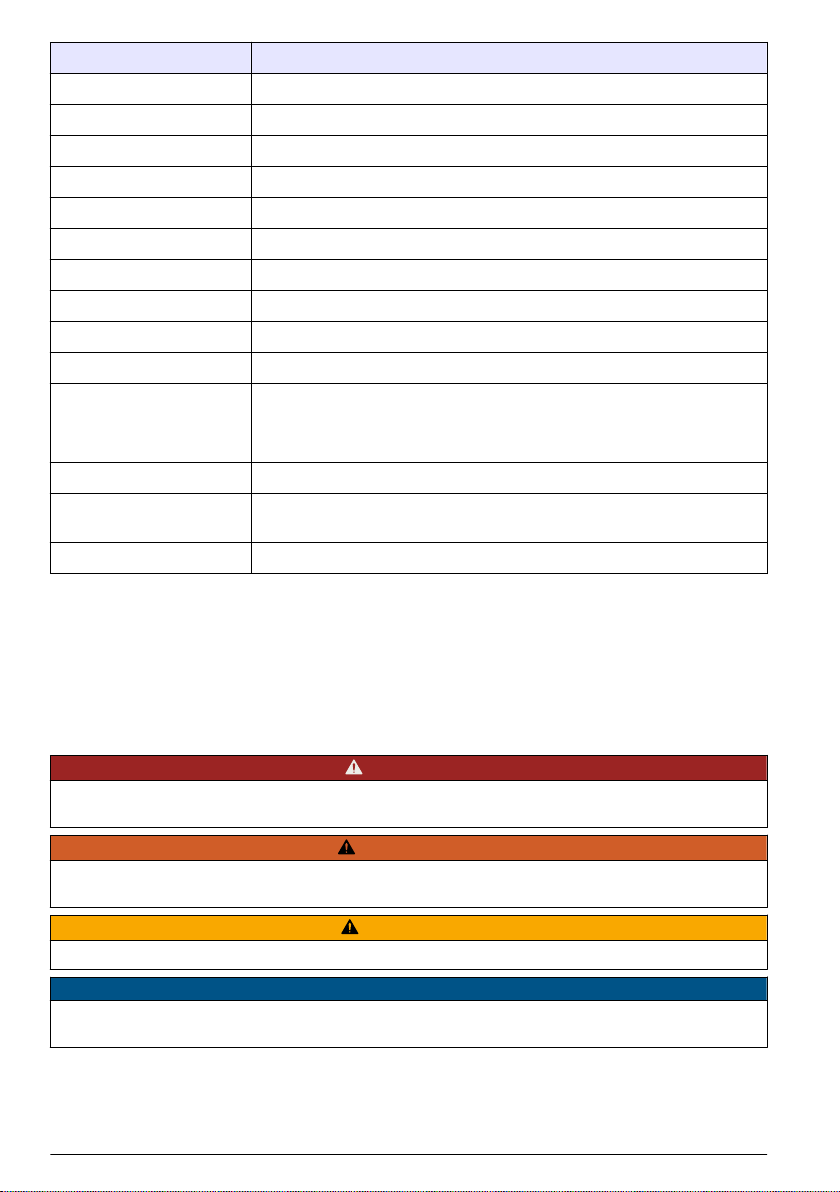

Section 3 Safety information............................................................................... 4

3.1 Intended use ....................................................................................................... 4

3.2 Use of hazard information..................................................................................... 4

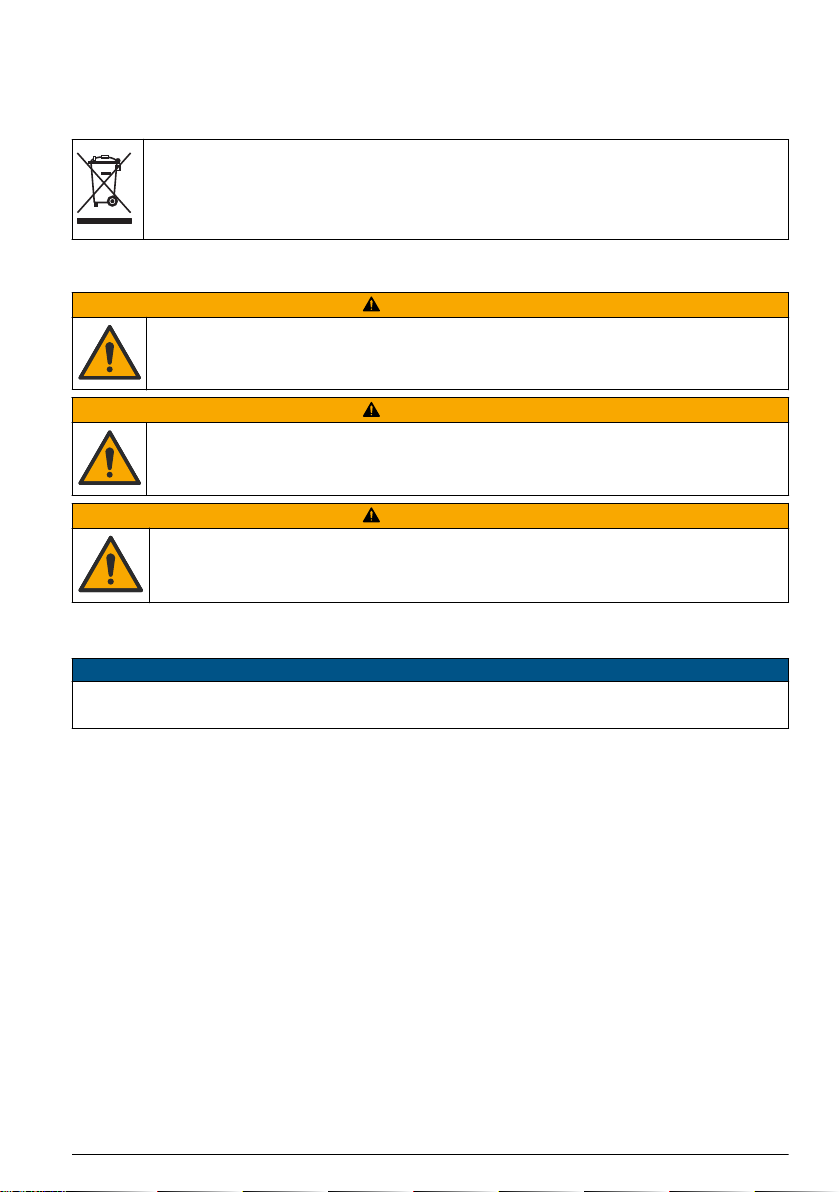

3.3 Precautionary labels............................................................................................. 5

3.4 Product hazards.................................................................................................... 5

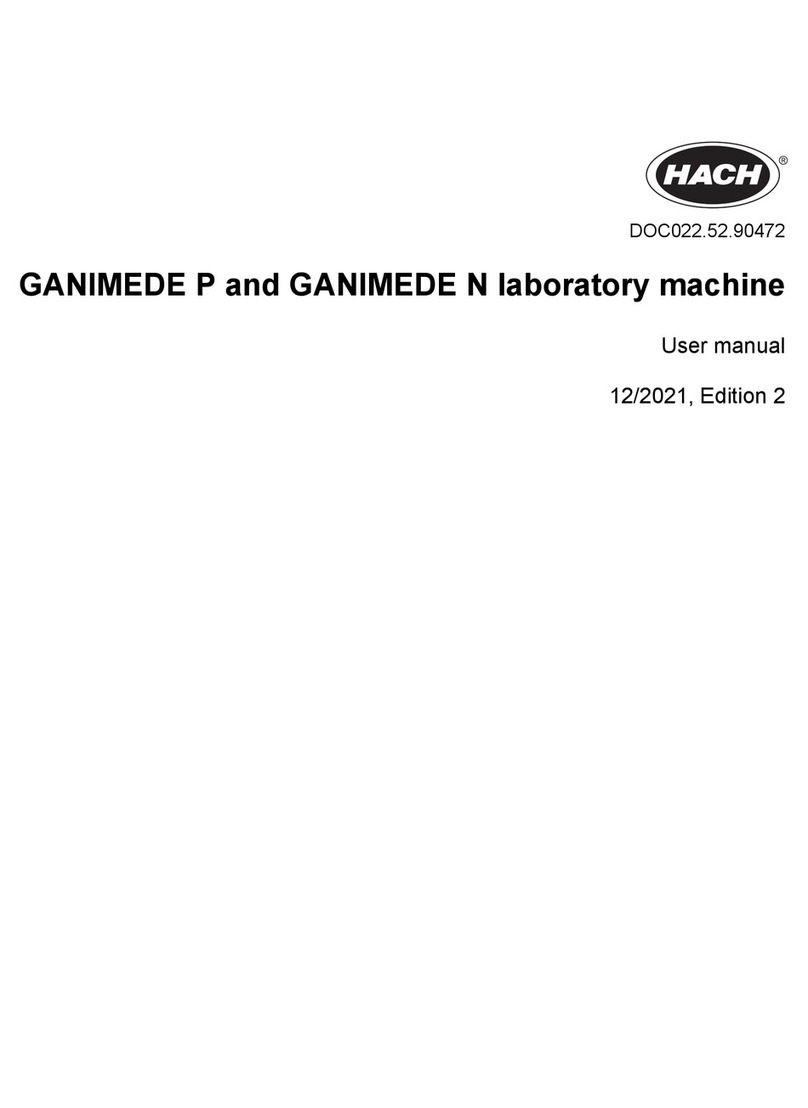

Section 4 Preparation for use.............................................................................. 5

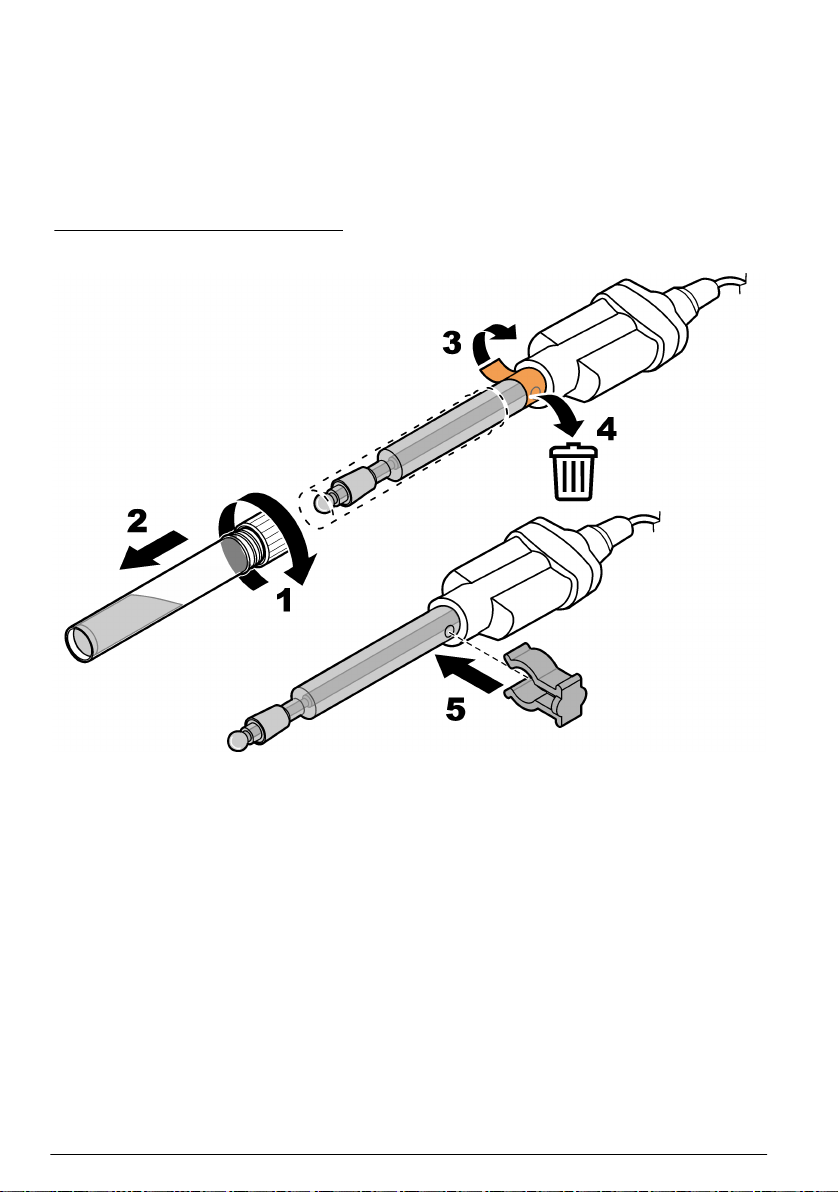

4.1 Operate the sleeve junction.................................................................................. 7

Section 5 Calibration.............................................................................................. 8

5.1 Calibration notes................................................................................................... 8

5.2 Calibration procedure........................................................................................... 9

Section 6 Sample measurement .................................................................... 10

6.1 Sample requirements.......................................................................................... 10

6.2 Sample measurement notes............................................................................... 10

6.3 Sample measurement procedure....................................................................... 10

Section 7 Verify the calibration........................................................................ 11

7.1 Verification procedure......................................................................................... 11

Section 8 Maintenance......................................................................................... 12

8.1 Clean the probe.................................................................................................. 12

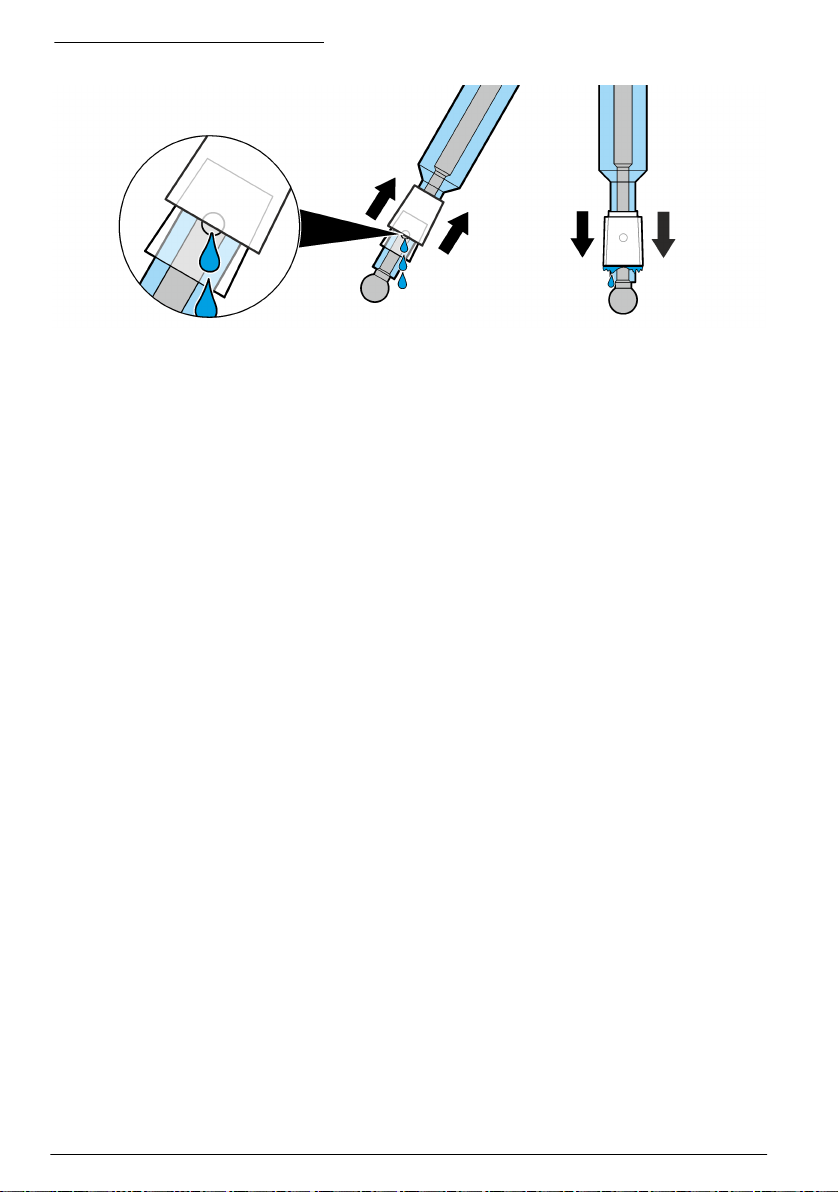

8.1.1 Clean the sleeve junction......................................................................... 13

8.2 Fill the probe....................................................................................................... 14

8.3 Add KCl crystals to the probe............................................................................. 14

8.4 Replace the filling solution.................................................................................. 16

8.5 Soak procedure for dry probes........................................................................... 17

8.6 Storage............................................................................................................... 17

Section 9 Troubleshooting ............................................................................... 18

Section 10 Consumables..................................................................................... 19

10.1 Recommended standards................................................................................. 19

10.2 Accessories...................................................................................................... 20

1