the FCC rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated

in a commercial environment. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference

to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference, in which case the user will be

required to correct the interference at their expense. The following

techniques can be used to reduce interference problems:

1. Disconnect the equipment from its power source to verify that it is or

is not the source of the interference.

2. If the equipment is connected to the same outlet as the device

experiencing interference, connect the equipment to a different

outlet.

3. Move the equipment away from the device receiving the interference.

4. Reposition the receiving antenna for the device receiving the

interference.

5. Try combinations of the above.

2.2 Product overview

Respirometric Biological Oxygen Demand (BOD) is a test that measures

the quantity of oxygen consumed by bacteria that oxidize organic matter

in a water sample. The test is used to measure waste loadings at

wastewater treatment plants and to examine the efficiency of wastewater

treatment.

The instrument is sealed to prevent external atmospheric pressure

changes in the test bottle. The pressure in the sample bottles is

monitored. Bacteria in the sample use oxygen when they consume

organic matter. This oxygen consumption causes the pressure in the

bottle head space to drop. The pressure drop correlates directly to BOD.

During a test period, stir bars mix the sample and cause oxygen to move

from the air in the bottle to the sample. This helps simulate natural

conditions.

Carbon dioxide is a result of the oxidation process and can interfere with

a measurement. The instrument continuously removes carbon dioxide

from the system so that the monitored pressure difference stays

proportional to the quantity of oxygen used. Pressure changes in the

closed system are shown graphically in milligrams per liter (mg/L) on a

liquid crystal display. The instrument gives 360 uniform data points over

the selected time period.

The instrument adjusts for any negative errors produced when heat is

applied to a sample. The instrument does not start the test until the

temperature gets to equilibrium.

2.3 Product components

Make sure that all components have been received. If any of these items

are missing or damaged, contact the manufacturer or a sales

representative immediately.

• BODTrak™ II instrument

• A UL/CSA approved 115 VAC power cord with a NEMA 5-15P style

plug

• A 230 VAC harmonized power cord with a continental European plug

• Power supply, auto-switching between 115 V and 230 V

• Seal cups (6x)

• BODTrak II amber sample bottles (6x)

• BODTrak II magnetic stir bars (6x)

• Spatula scoop

• Nutrient buffer solution pillows (1 pkg)

• Potassium hydroxide pellets (1 container)

Section 3 Installation

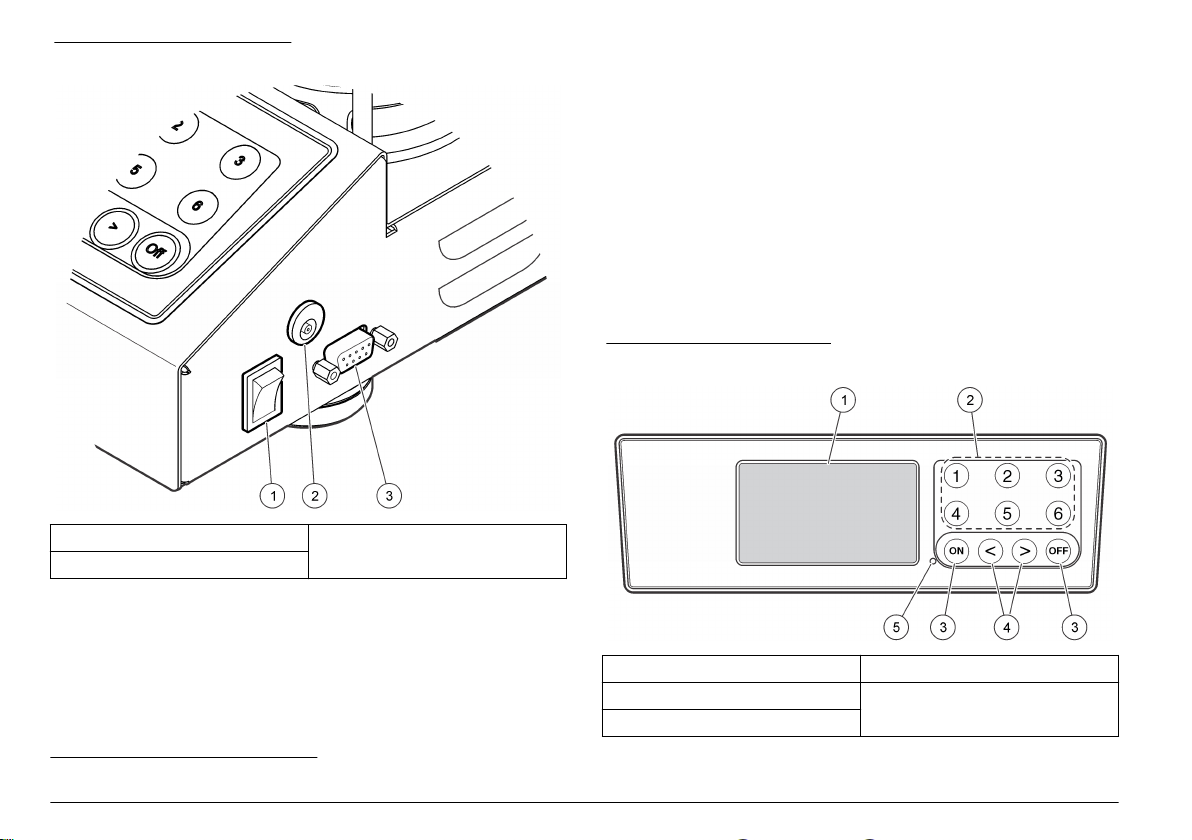

3.1 External connections

Figure 1 shows the locations of the power switch and external

connections.

English 5