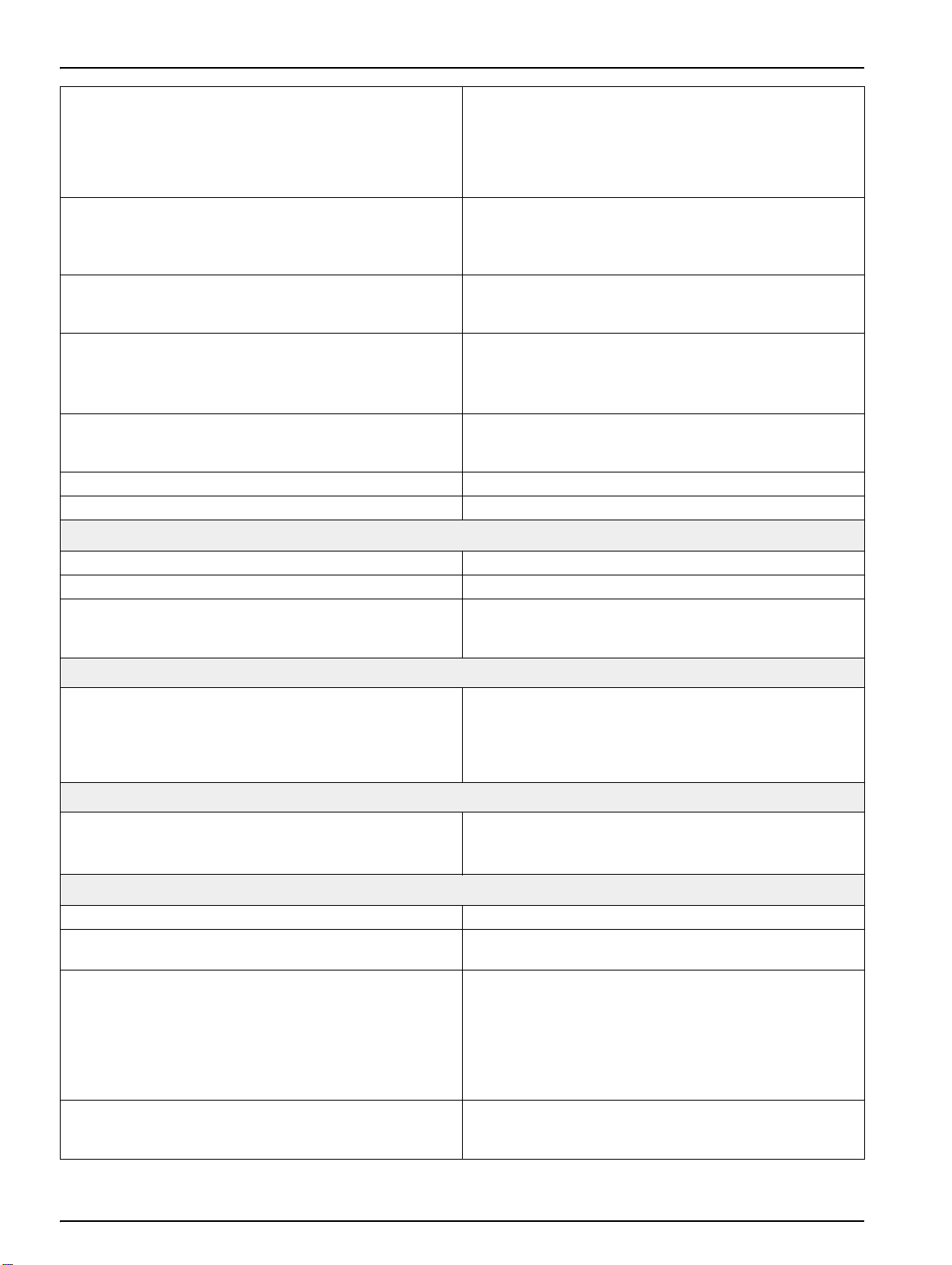

4

6.2.2.1 Liquid depth...............................................................................................................73

6.2.2.2 Sensor height ............................................................................................................74

6.2.2.3 Setting the invisible range .........................................................................................74

6.3 Submerged area/velocity sensor.................................................................................................74

6.3.1 Submerged area/velocity sensor programming..................................................................75

6.4 Submerged pressure sensor.......................................................................................................75

6.4.1 Submerged pressure sensor connection............................................................................75

6.4.2 Submerged pressure sensor programming........................................................................76

6.4.3 Submerged pressure sensor calibration.............................................................................76

6.5 Thermal sensor ...........................................................................................................................77

6.5.1 Thermal sensor programming ............................................................................................78

6.5.2 Thermal sensor calibration.................................................................................................78

Section 7 Optional device installation...................................................................................79

7.1 Rain gauge..................................................................................................................................79

7.1.1 Rain gauge programming...................................................................................................80

7.2 pH probe......................................................................................................................................80

7.2.1 pH probe connection..........................................................................................................80

7.2.2 pH probe programming.......................................................................................................82

7.2.3 pH probe calibration ...........................................................................................................82

7.3 ORP probe ..................................................................................................................................83

7.3.1 ORP probe connection.......................................................................................................83

7.3.2 ORP probe programming ...................................................................................................84

7.3.3 ORP probe calibration........................................................................................................84

7.3.3.1 ORP preamplifier/junction box calibration .................................................................84

7.4 Dissolved oxygen probe..............................................................................................................85

7.4.1 Dissolved oxygen probe connection...................................................................................85

7.4.2 Dissolved oxygen probe programming...............................................................................85

7.4.3 Dissolved oxygen probe temperature programming...........................................................85

7.4.4 Dissolved oxygen probe calibration....................................................................................85

7.5 Conductivity probe.......................................................................................................................86

7.5.1 Conductivity probe connection...........................................................................................86

7.5.2 Conductivity probe programming........................................................................................86

7.5.3 Conductivity temperature programming .............................................................................87

7.5.4 Conductivity probe calibration............................................................................................87

Section 8 Communication setup............................................................................................91

8.1 RS232 cable................................................................................................................................91

8.1.1 RS232 connection..............................................................................................................91

8.1.2 RS232 programming ..........................................................................................................91

8.2 Modem ........................................................................................................................................92

8.2.1 Modem connection.............................................................................................................92

8.2.2 Modem programming .........................................................................................................92

8.2.2.1 Pager option..............................................................................................................93

8.2.2.2 Reporting devices......................................................................................................94

8.3 4–20 mA option...........................................................................................................................96

8.3.1 4–20 mA programming.......................................................................................................96

8.3.2 4–20 mA calibration............................................................................................................97

8.4 Alarm relays ................................................................................................................................98

8.4.1 Alarm relays connection.....................................................................................................99

8.4.2 Alarm relays programming ...............................................................................................100

8.4.2.1 Trouble alarms.........................................................................................................100

8.4.2.2 Set Point alarms......................................................................................................101

8.5 Analog inputs.............................................................................................................................102

8.5.1 Analog inputs connection.................................................................................................102

Goodnal STP ST041 Pre Treatment (Sigma 900 MAX All Weather Refrigerated Sampler) Vendor Manual