Please read through the instructions

carefully before using the unit and

carefully note the safety advice.

Always keep this manual accessible

to any users of the drill.

Area of Application

The control unit can be set up in a

cabinet, or can be used as a

portable unit (e.g., in a carry case).

It is suitable for the following

scopes: foot care / manicure

(milling, trimming and polishing).

Attention: Additional spray or

suction might have to be in

operation during foot care in your

country.

Installation Site

The installation of the workroom

must correspond to any regulations

according to your country laws. Set

up the control unit, so that the

ventilation slits are not covered or

blocked, and the exhaust air can

escape well. The unit may only be

used in closed rooms.

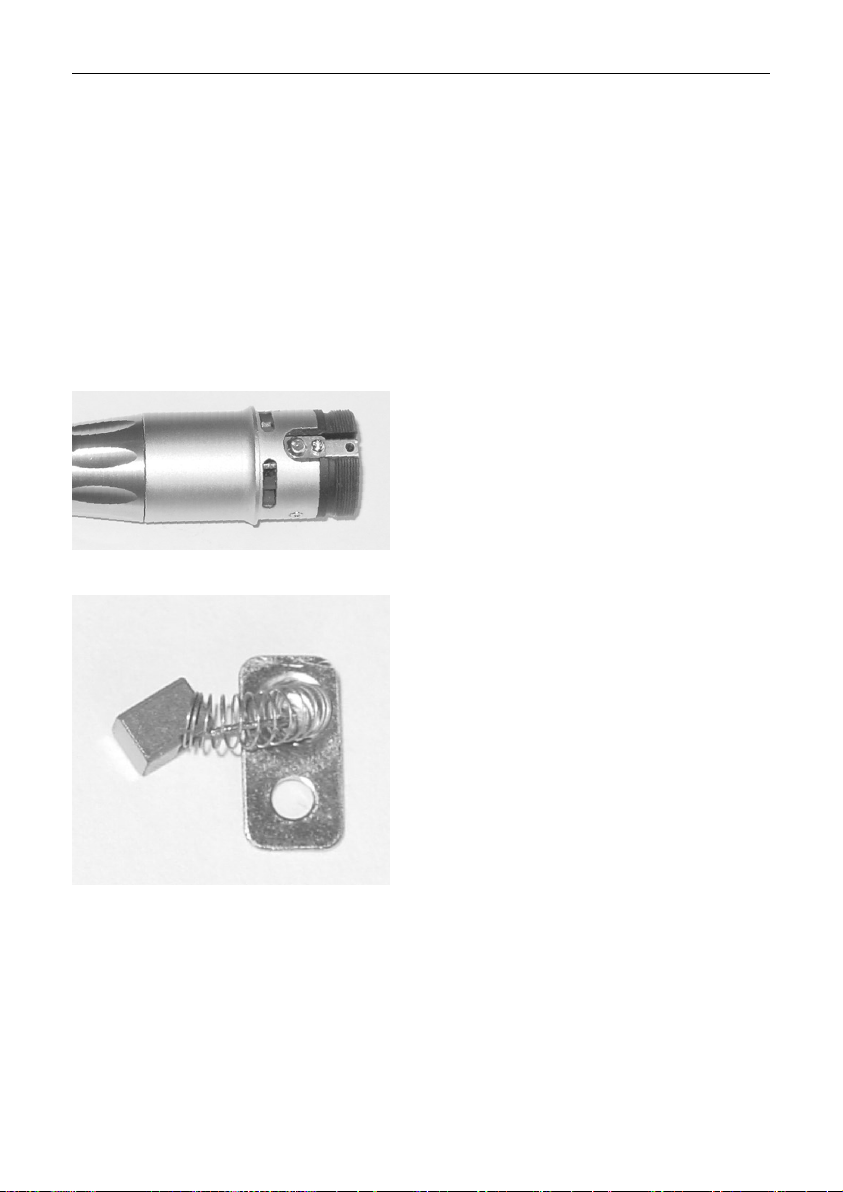

Clamping the Bur/Tool

Hold the handpiece with one hand

at the A area. Turn with your other

hand ring B clockwise until it snaps

in. Now the clamp is open. Insert

the bur all the way to the stop. Turn

ring B counter clockwise until it

snaps in.

Check that the bur is clamped

correctly and cannot be pulled out.

You may never turn on the unit

while the chuck is open. This may

cause damages at the motor and

the electronic.

For security reasons, only

change the tool if the

handpiece is turned off.

Adjusting the Speed

Switch on the unit by turning the

button clockwise from position OFF

to MIN.

The handpiece only starts at

minimum speed. By turning the

button more in a clockwise

direction, you will raise the speed.

Cleaning & Disinfection

After every treatment please

carry out the following steps:

Remove the rotating tool (e.g. bur,

capper etc.) first. Then handle the

cleaning of the tool according to the

instructions of its manufacturer.

Remove tissue remains by wiping

off the unit with a mildly moistened

paper cloth. Afterwards clean all

surfaces with disinfection cloth (e.g.

Mikrozid AF Tücher of Schülke and

Mayr).

The charging unit is only to be

cleaned with a dry cloth.