hadewe Xantos-Nail 0872 User manual

art. 0872

FB 04-182 Rev. 5

Date: 21.01.2019

Manual

Xantos-Nail

2

Contents

Safety Instructions 3

Cleaning & Disinfection 7

Getting to Know the Unit 8

Before First Use 9

Area of Application 9

Installation Site 9

Application 10

Starting up and Operating the Unit 10

Clamping the Bur/Tool 10

Setting up the Speed 10

Maintenance & Care 11

Handling Instructions 12

Troubleshooting 13

Technical Data 15

3

Safety Instructions

Read this instruction manual in its entirety

before you start operating the unit. Especially

read through any information regarding the

battery and recharging process to prevent

damage to the accumulators.

The equipment should only be used by

trained operators.

The installation of the working area has to

correspond to the relevant regulations. Set

up the unit in such a way, that the air slits are

not blocked and the extracted air can escape

well.

Only switch on the unit, if the handpiece

rests secured in the handpiece holder, or if

you hold it safely in your hand.

To avoid the risk of electrocution only

connect the device to the mains power

supply.

If you pull the power plug it will stop the

connection to the mains power supply. Set

up the unit so that the power plug is always

accessible. The power switch should also

always be easily accessible.

Prevent any liquids from entering into the

control unit, since this could damage the

electronic elements. Clean the outside of the

box only with a damped cloth. Make sure,

4

Safety Instructions

that you have unplugged the unit before.

Check the mains cable regularly for damage,

and in case of such, have it changed or

repaired by an authorized service center.

Prevent your hair from wrapping itself around

moving parts. If applicable, wear a hair net.

When working with materials, which might

create dust or moisture, use a drilling unit

with suction or spray technique. Wear a nose

and mouth protection. Always follow the

safety instructions, provided by the

manufacturer of the materials being formed

and used.

For safety reasons wear goggles during the

treatment.

Ensure that the patient’s foot and the

handpiece are held firmly in place during the

operation. To prevent injury, work with

extreme caution on the foot of the patient

and use only light pressure.

To ensure that the bur/ tool sits firmly in the

chuck, do not work with tools which

•have an oily shaft,

•are worn,

•are bent.

5

Safety Instructions

This appliance can be used by children aged

from 8 years and above and persons with

reduced physical, sensory or mental

capabilities or lack of experience and

knowledge if they have been given

supervision or instruction concerning use of

the appliance in a safe way and understand

the hazards involved.

Children should be supervised not to play

with the appliance.

Before using the equipment, assure that

•the tool can be pushed far enough into the

chuck,

(Test this with a dipstick and clean the

handpiece if necessary.)

•the inserted tool sits properly in the chuck

and will not cant/jam while clamping it,

•the tool is approved for using it at the max

speed (see manufacturer’s instructions) or

only use the speed required by the

instrument,

•the tool is absolutely dry.

For safety reasons do not change the tool

while the motor is running.

Switch off the unit immediately if

•the bur comes off during the treatment

itself,

6

Safety Instructions

•the motor blocks during the treatment.

Regularly check the mechanical safety of the

unit (look for damages to the housing or

mains cable for example).

Always follow the operating instructions.

Do not carry out any repairs, modifications or

maintenance work yourself. This is only to be

accomplished by an authorized specialist.

The mains cable may also only be changed

by the manufacturer, or an authorized

specialist. Never remove the housing,

especially not while the equipment is plugged

into the socket, since some components are

under electric voltage. Any unauthorized or

improper handling (e.g. trying to repair the

unit) of the equipment will immediately nullify

the guarantee/warranty, and any other

liabilities of the manufacturer.

7

Cleaning & Disinfection

After every treatment please carry out the following steps:

•Remove the rotating tool (e.g. bur, capper, etc.) first. Then

handle the cleaning of the tool according to the instructions

of its manufacturer.

•Remove tissue remains by wiping off the unit with a mildly

moistened paper cloth. Afterwards clean all surfaces with

disinfection cloth (e.g. Mikrozid AF Tücher of Schülke and

Mayr).

8

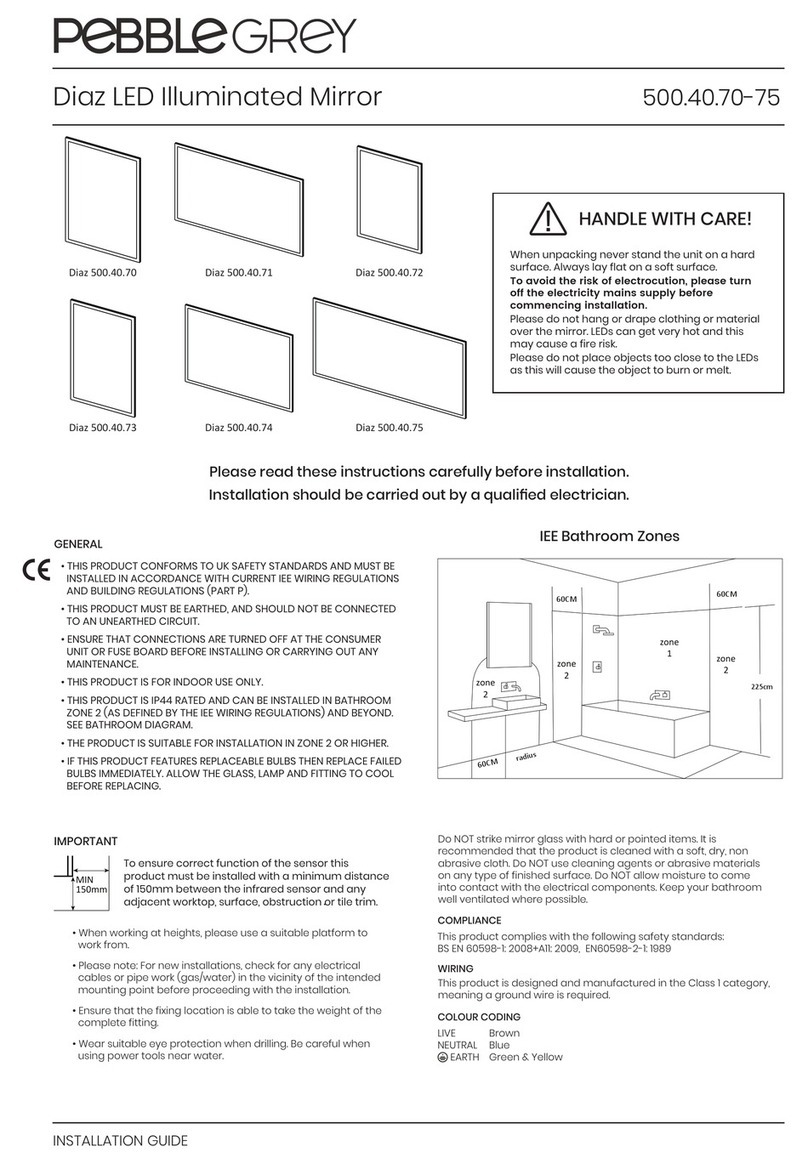

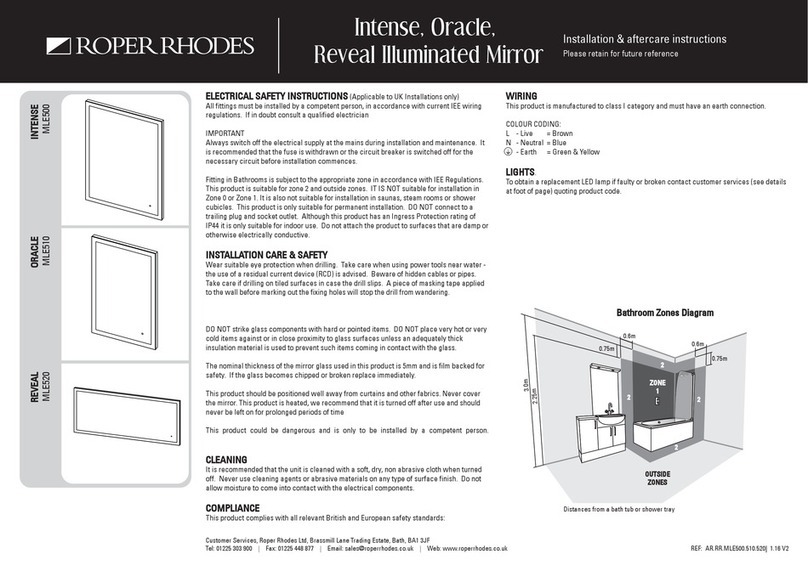

Getting to Know the Unit

1. speed display

2. LED

3. increase speed

4. change direction

of rotation

5. decrease speed

6. ON/OFF button

8

9

Before First Use

Please read through the instructions

carefully before using the unit and

carefully note the safety advice.

Always keep this manual accessible

to any users of the drill.

Area of Application

The control unit can be set up in a

cabinet or can be used as a

portable unit (e.g. in a carry case). It

is suitable for the following scopes:

•foot care/manicure

(milling, trimming and polishing)

Attention: Additional spray or

suction might have to be in

operation during foot care in your

country.

•dental technique/dental laboratory

(Milling, trimming and polishing

work at plaster casts and models)

Do not use this unit for dentist

purposes, i.e. working directly

on the patient.

•industry

(grinding, milling and polishing

works)

Installation Site

The installation of the workroom

must correspond to any regulations

according to your country laws. Set

up the control unit, so that the

ventilation slits are not covered or

blocked, and the exhaust air can

escape well.

The drill and the charging unit may

only be operated in confined

spaces. Temperature rising of the

housing is normal during operation.

Although the unit should never be

covered, nor be located near

heating devices or in direct sun

impact.

10

Application

Starting up and Operating

the Unit

Put down the handpiece in the

handpiece holder. Plug in the plug.

Turn on the unit with button 6. With

button 3 and 5 you can adjust the

speed level. Regularly the drill runs

clockwise. To change the direction,

push button 4. While the drill runs

with the left rotation the green LED

(no 2 in pic.1) is shining.

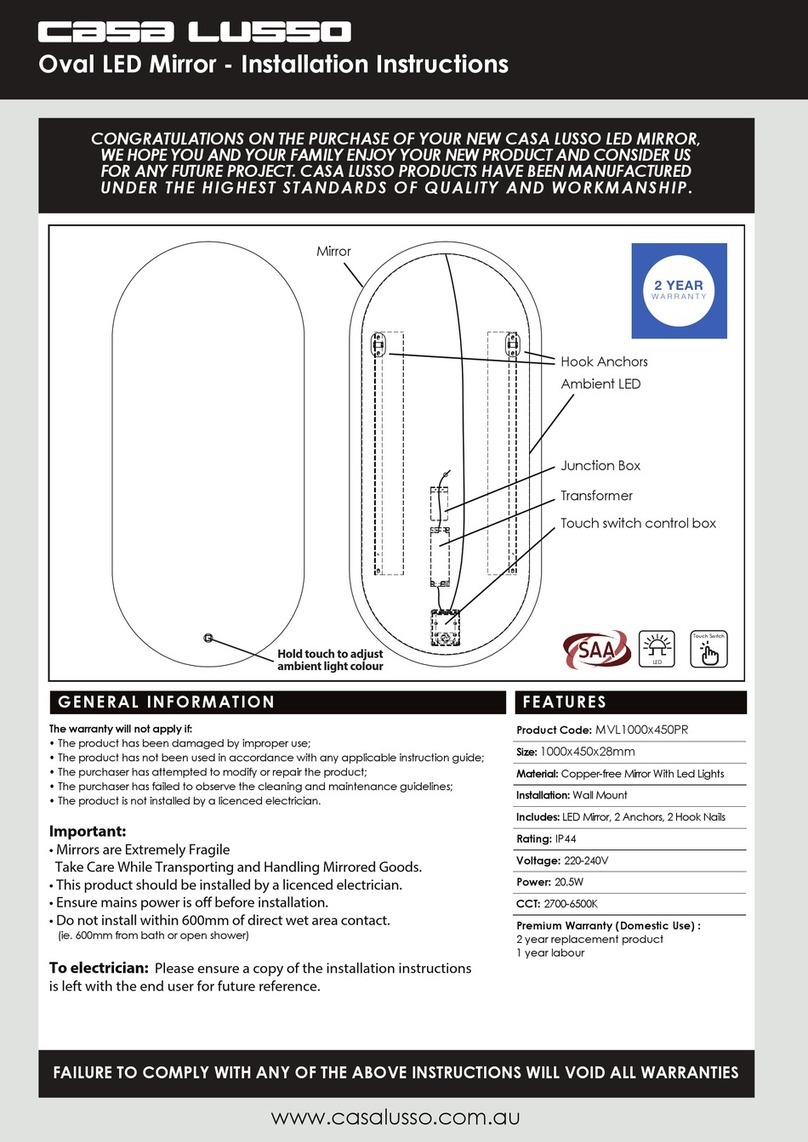

Clamping the bur/tool

The handpiece is equipped with a

chuck, which can hold all burs with

a diameter of 2,35 mm (this is the

diameter usually used for tools in

podiatry).

Keep the handpiece at spot A in

one hand. Turn the ring (spot B)

clockwise with your free hand until it

snaps. Now the chuck is opened.

Insert the bur until the end of the

chuck. Screw the ring B counter

clockwise until it snaps. Check, if

the bur sticks well.

It sticks well when you cannot pull it

out. Please do not turn on the unit

while the chuck is opened. This can

damage the motor and the

electronic devices.

For security reasons, only

change the tool if the

handpiece is turned off.

Setting up the Speed

Hold the handpiece (incl. tool) in

your hand or store it in the

handpiece holder attached to the

side of the control unit.

Switch on the unit with button (6).

Now you can also set the speed

with buttons (3) and (4). Choose the

direction of rotation with button (5).

In reverse running the LED (2) will

be on.

Table of contents

Other hadewe Personal Care Product manuals